MnO2@Mn3O4 core-shell octahedral particle/net-shaped graphene composite electrode material

A technology of meshed graphene and composite electrodes, which is applied in the fields of hybrid capacitor electrodes and hybrid/electric double layer capacitor manufacturing, etc., achieves the effects of simple experimental device and preparation process, good industrial application prospects and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] mn 3 o 4 Preparation of octahedral nanoparticles:

[0034] Weigh 0.57g of manganese acetate tetrahydrate and 0.3g of polyvinylpyrrolidone and dissolve them in 35mL of water. After magnetically stirring for 30 min, the mixed solution was transferred to a 50 mL polytetrafluoroethylene reactor, and reacted at a constant temperature of 150° C. for 3 hours. After being naturally cooled to room temperature, it was centrifuged at 8000 rpm, washed three times with deionized water and ethanol, and finally dried in an oven at 60 degrees Celsius to obtain Mn 3 o 4 octahedral particles.

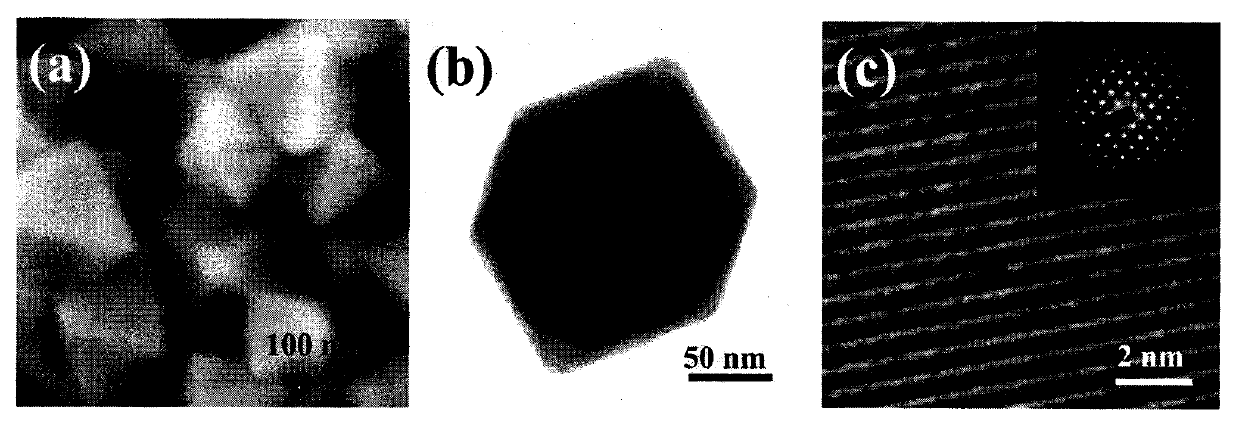

[0035] figure 1 a is the SEM figure of the product obtained in Example 1. It can be seen from the figure that the product presents a regular octahedral morphology with a relatively narrow size distribution. figure 1 b is a high-magnification TEM image, the edges and corners of the octahedron are clear, and each face is very smooth. From the HRTEM plot ( figure 1 c) It can be seen that the...

Embodiment 2

[0037] Core-shell MnO 2 @Mn 3 o 4 Preparation of nanoparticles:

[0038]Weigh 0.04g of the above Mn 3 o 4 The particles and 0.0316 g of potassium permanganate were dissolved in 30 mL of deionized water, then transferred to a 50 mL autoclave, and reacted at 160 °C for 10 hours. After centrifugation, repeated washing, and drying in an oven at 60 degrees Celsius, MnO with a core-shell structure is obtained. 2 @Mn 3 o 4 Nanoparticles.

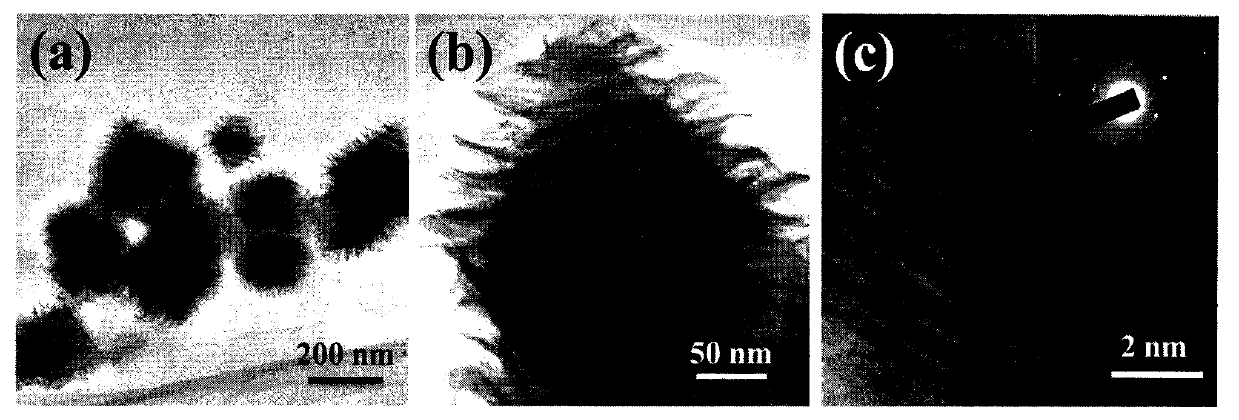

[0039] figure 2 a is the SEM figure of the product prepared in Example 2. From figure 2 It can be seen in a that the product still retains the octahedral appearance, but the surface is very rough and the size becomes larger. The surface of each octahedral particle is uniformly covered with nanosheets. figure 2 b is a high-magnification TEM image. It can be seen that the thickness of the nanosheets is about 50 nm, and the nanosheets cross each other. From the HRTEM map ( figure 2 c) It is concluded that the surface-covered nanoshee...

Embodiment 3

[0041] MnO 2 @Mn 3 o 4 / NG composite electrode material preparation:

[0042] Weigh 0.01g of graphite oxide and disperse it in 34mL of deionized water. After ultrasonication at 540W for 80min, add 0.01g of the above core-shell structure MnO 2 @Mn 3 o 4 Particles were stirred by magnetic force for 1 hour; then 1 mL of ethylenediamine was added, and stirring was continued for 15 minutes. Transfer the mixed solution to a 50mL reactor, and react at a constant temperature of 150 degrees Celsius for 3 hours to obtain a columnar product. After soaking in deionized water for 12 hours, freeze-dry to obtain the final product MnO 2 @Mn 3 o 4 / NG.

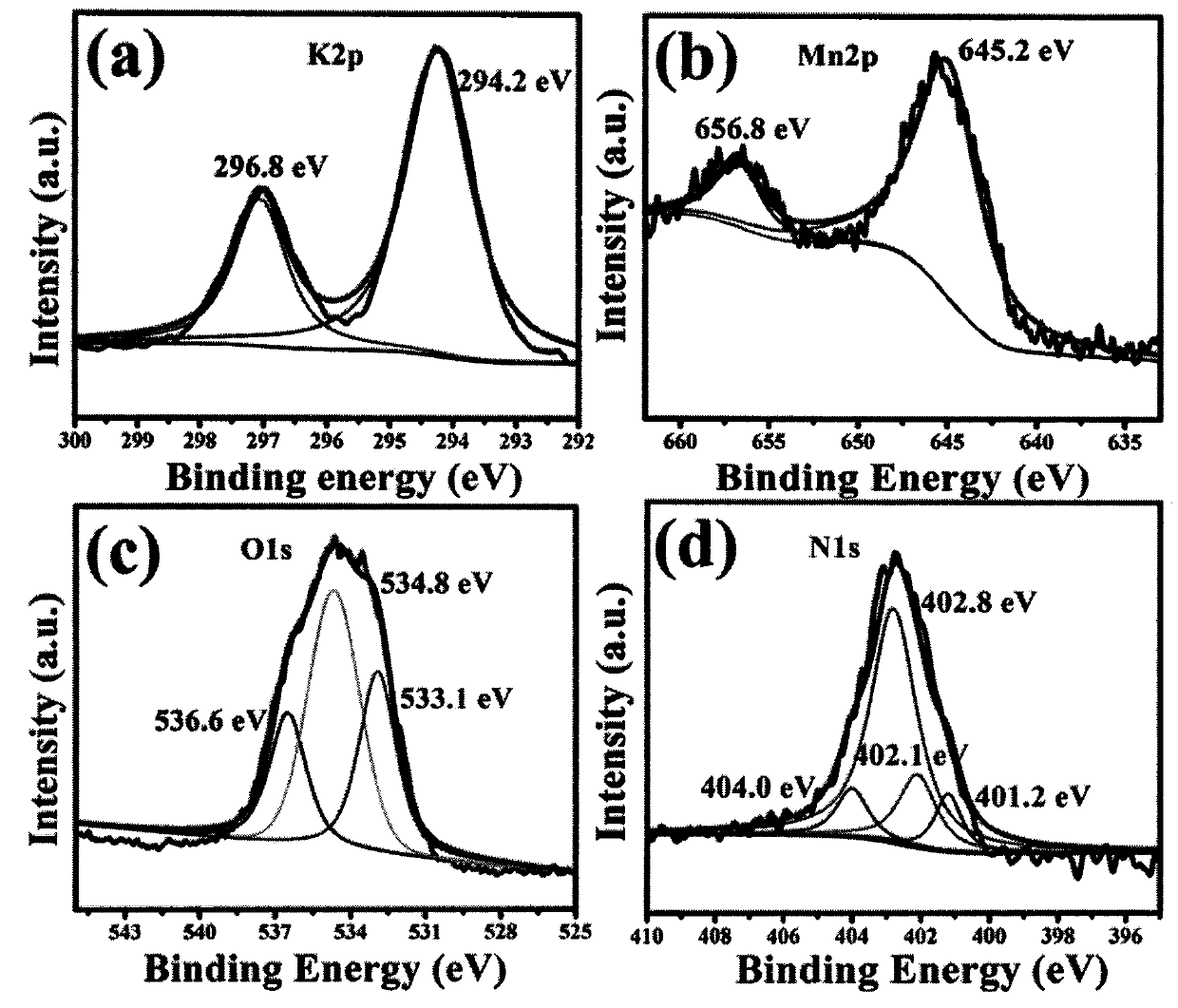

[0043] image 3 Final product MnO prepared for embodiment 3 2 @Mn 3 o 4 / NG high-resolution XPS spectrum. The high-resolution XPS spectrum of K2p ( image 3 a) shows that K+ exists in MnO 2 in phase. In the high resolution XPS spectrum of Mn2p ( image 3 In b), the two characteristic peaks are located at 645.2eV and 656.8eV re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interplanar spacing | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com