Carbon fiber and preparation method thereof, and application of carbon fiber, electrode and vanadium redox flow battery

A carbon fiber and fiber technology, applied in the field of flow batteries, can solve the problems of complex preparation process, low surface activity, low conductivity, etc., and achieve the effects of high surface activity, improved surface reactivity, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

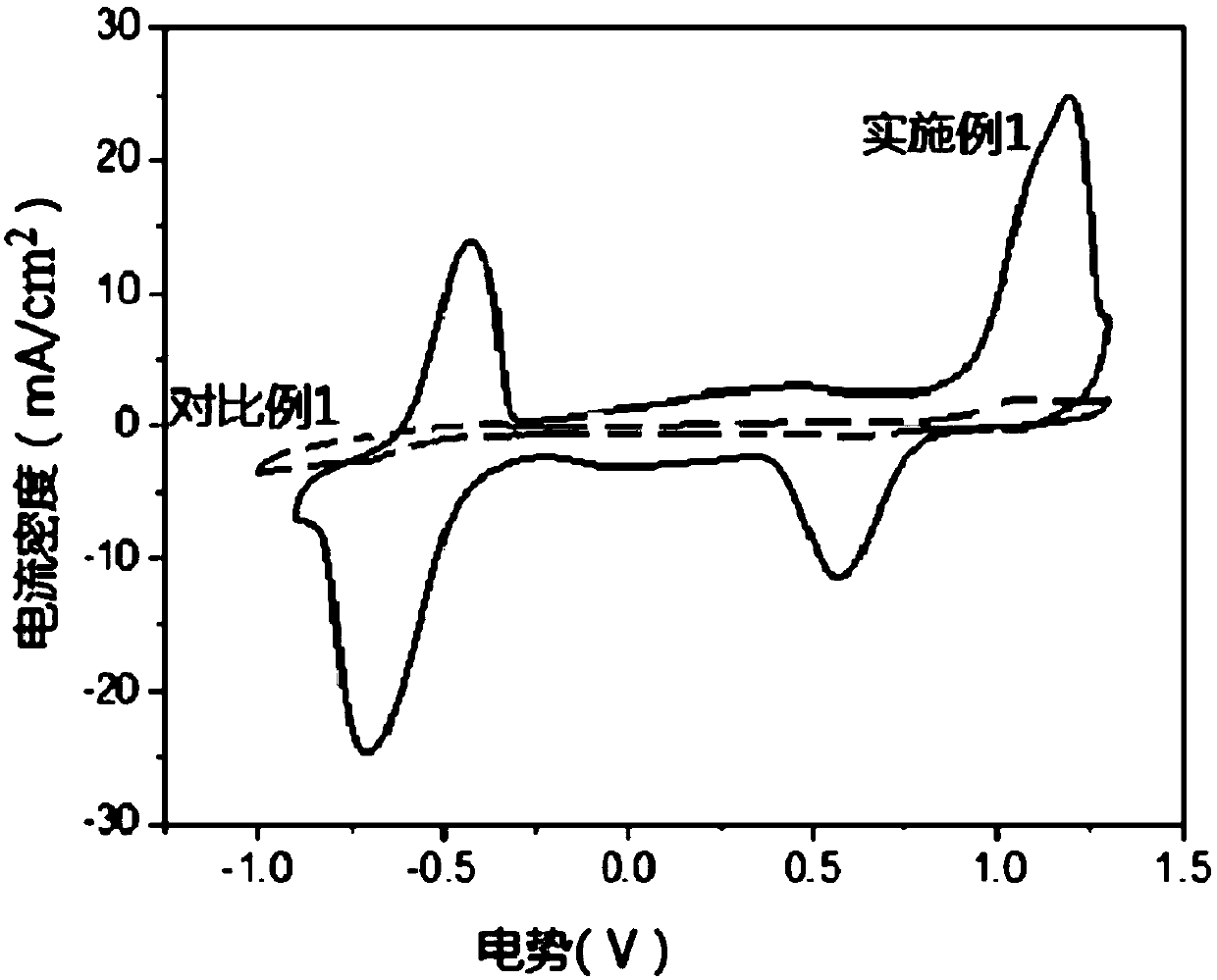

Image

Examples

Embodiment approach

[0028] According to a preferred embodiment of the present invention, the interlayer distance d002 of the carbon fiber has a value of 0.3354-0.3396 nm, more preferably 0.3354-0.3370 nm. The interlayer d002 value of the carbon fiber provided by the present invention is smaller than that provided by the prior art, and the interlayer d002 value of the carbon fiber provided by the prior art is generally greater than 0.3450nm.

[0029] According to a preferred embodiment of the present invention, the radial graphite crystallite size Lc of the carbon fiber is 35.6-86.7 nm, more preferably 40-60 nm. The carbon fiber provided by the present invention has a relatively large Lc value of graphite crystallite size in the radial direction of the fiber, and the Lc value of the carbon fiber provided by the prior art is generally less than 2nm.

[0030] According to a preferred embodiment of the present invention, the fiber axial graphite crystallite size La value of the carbon fiber is 43-80 ...

Embodiment 1-3

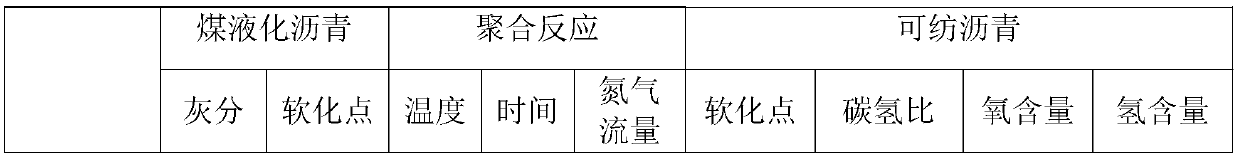

[0065] (1) 600g of coal liquefied pitch (provided by Shenhua Group Coal-to-Liquid Chemical Industry Research Institute) is broken into powder, added to the reactor, and polymerized to obtain spinnable pitch, the ash content (% by weight) and softening point (weight %) of coal liquefied pitch ( ℃), polymerization reaction temperature (℃), time (h), nitrogen flow rate (ml / min / g) and the softening point (℃) of the obtained spinnable pitch, carbon-hydrogen ratio, oxygen content (weight %), hydrogen See Table 1 for content (weight %) data.

[0066] (2) Spinnable pitch is added to the spinning tank, and spinning is carried out to obtain pitch fiber precursors, spinning temperature (°C), spinning pressure (MPa), spinning speed (m / min) and the fibers of pitch fiber precursors See Table 2 for diameter (μm) data.

[0067] (3) The pitch fiber precursors were oxidized and stabilized to obtain pre-oxidized fibers. The temperature (° C.), time (h) and air flow (ml / min / g) data of the oxidat...

Embodiment 4

[0078] According to the method of Example 1, the difference is that the temperature of oxidation modification in step (5) is 450° C., and the time is 1 h to obtain carbon fibers. The results of carbon fiber analysis are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com