Method for preparing rice flour by combining pure strain fermentation with semidry method flour grinding

A semi-dry method and rice noodle technology, applied to bacteria, lactobacillus, food heat treatment, etc. used in food preparation, can solve the problems of not being able to obtain the flavor of traditional rice noodle, reduce the nutritional value of rice noodle, and the loss of beneficial metabolites, so as to shorten fermentation time, inhibition of bacterial contamination, and the effect of stabilizing the flavor of fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

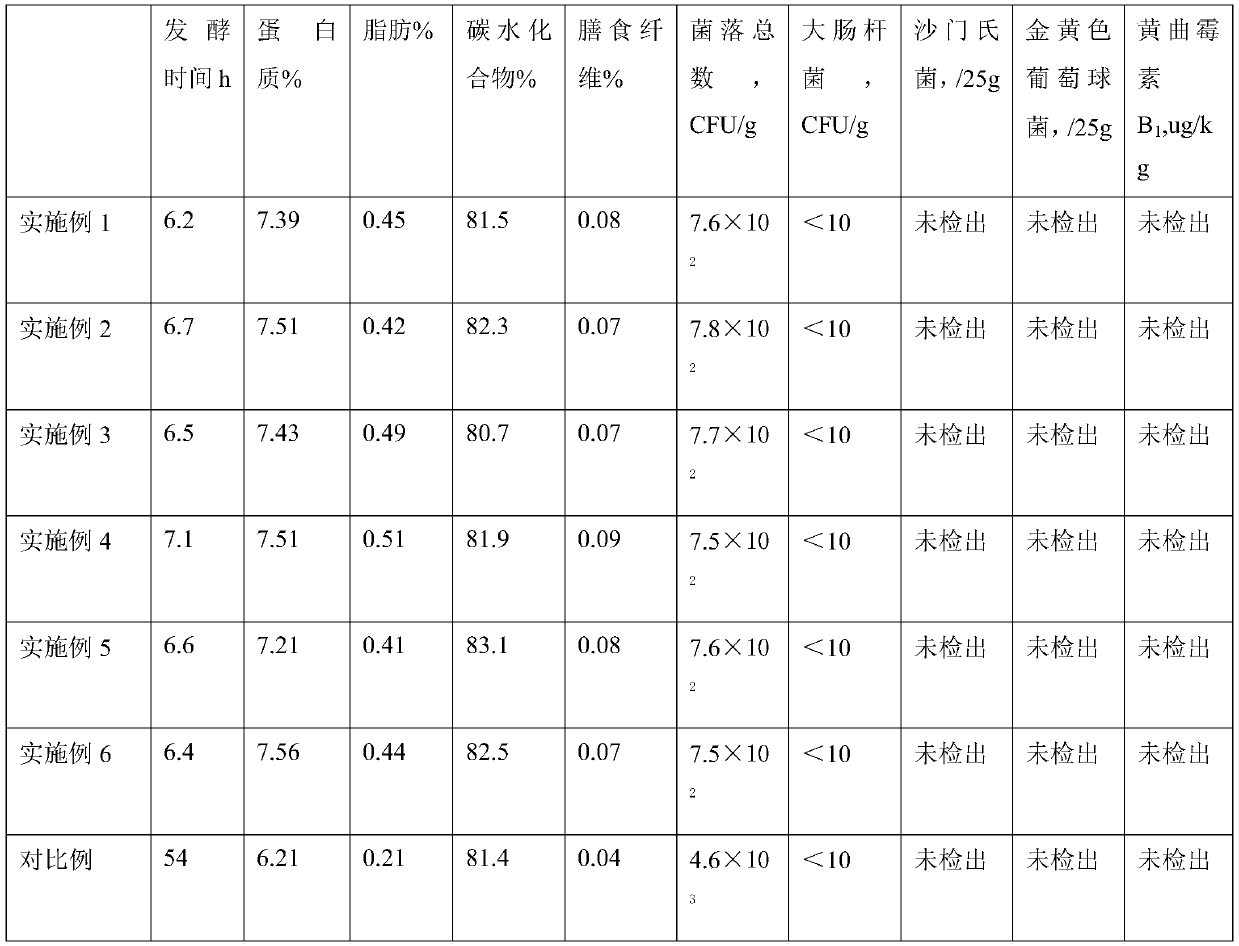

Examples

Embodiment 1

[0028] 1) Applying water to the indica rice grains quantitatively by spraying, and then continuously stirring, so that the indica rice grains are in uniform contact with the water, so that the moisture content of the indica rice grains is 28%;

[0029] 2) The indica rice grains processed in step 1 are pulverized by an airflow mill, and the indica rice flour passes through a 80-mesh sieve to obtain indica rice flour;

[0030] 3) mixing and stirring the indica rice flour and water to obtain indica rice slurry with a water content of 48%;

[0031] 4) Add a starter to the indica rice slurry and ferment in a sealed fermenter. The fermentation temperature is 35°C and the fermentation time is 4h. The starter is 40 parts by mass of Lactobacillus plantarum powder, 33 parts of Lactobacillus fermentum, 18 parts of saccharomyces, 1 part of Aspergillus oryzae, the starter is 0.1% of the dry weight of indica rice flour (calculated according to the 85% purity of the compound enzyme preparati...

Embodiment 2

[0037] 1) Apply water quantitatively to the indica rice grains by spraying, and then continuously stir, so that the indica rice grains are in uniform contact with the water, so that the moisture content of the indica rice grains is 32%;

[0038] 2) The indica rice grains processed in step 1 are pulverized by an airflow mill, and the indica rice flour passes through a 80-mesh sieve to obtain indica rice flour;

[0039] 3) mixing and stirring the indica rice flour and water to obtain indica rice slurry with a water content of 57%;

[0040] 4) Add a starter to the indica rice slurry and ferment in a sealed fermenter. The fermentation temperature is 37° C. and the fermentation time is 8 hours. The starter is 45 parts by mass of Lactobacillus plantarum powder, 38 parts of Lactobacillus fermentum, 22 parts of yeast, 2 parts of Aspergillus oryzae, the starter is 0.2% of the dry weight of indica rice flour (calculated according to the 85% purity of the compound enzyme preparation);

...

Embodiment 3

[0046] 1) Applying water to the indica rice grains quantitatively by spraying, and then continuously stirring, so that the indica rice grains are in uniform contact with the water, so that the moisture content of the indica rice grains is 29%;

[0047] 2) The indica rice grains processed in step 1 are pulverized by an airflow mill, and the indica rice flour passes through a 80-mesh sieve to obtain indica rice flour;

[0048] 3) mixing and stirring the indica rice flour and water to obtain indica rice slurry with a water content of 54%;

[0049] 4) Add a starter to the indica rice slurry and ferment in a sealed fermenter. The fermentation temperature is 37° C. and the fermentation time is 6.5 hours. The starter is 42 parts by mass of Lactobacillus plantarum powder and 35 parts of Lactobacillus fermentum , 21 parts of saccharomycetes, 1 part of Aspergillus oryzae, and described leavening agent is 0.1% of the dry weight of indica rice flour (calculated according to the 85% purity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com