Preparation of porous sulfur-doped graphite phase carbon nitride-reduced graphene oxide nanosheets

A technology of graphite phase carbon nitride and graphene nanosheets, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low utilization rate of visible light and avoid thermal stripping and solvent Exfoliation, good photoelectrochemical performance, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

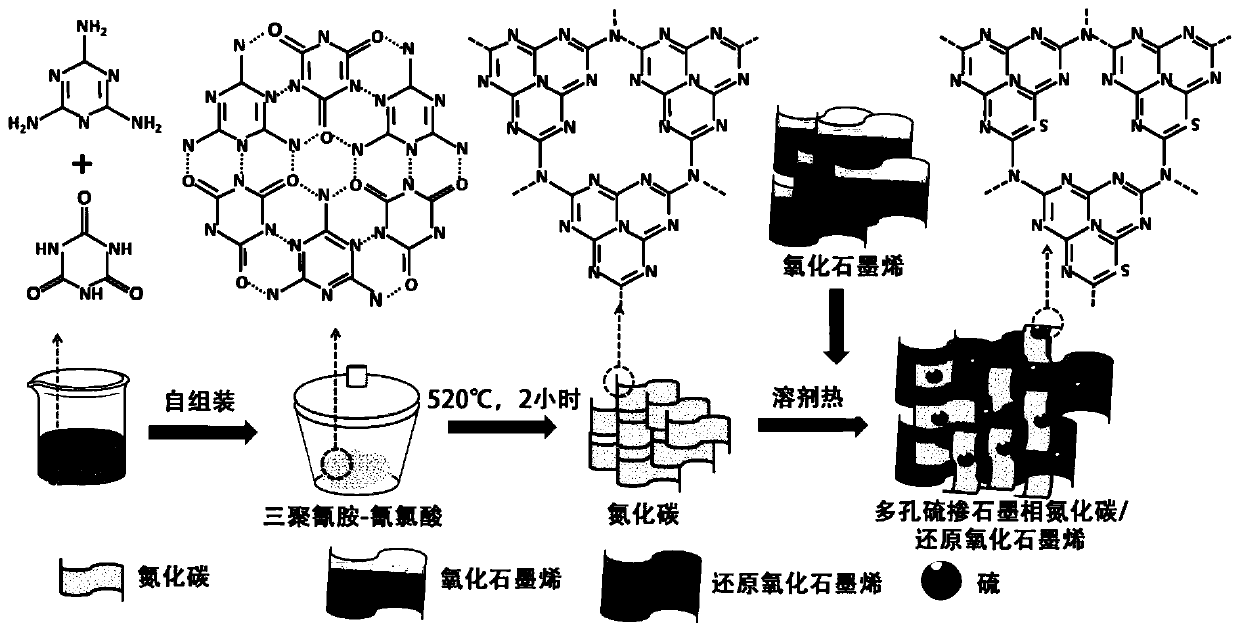

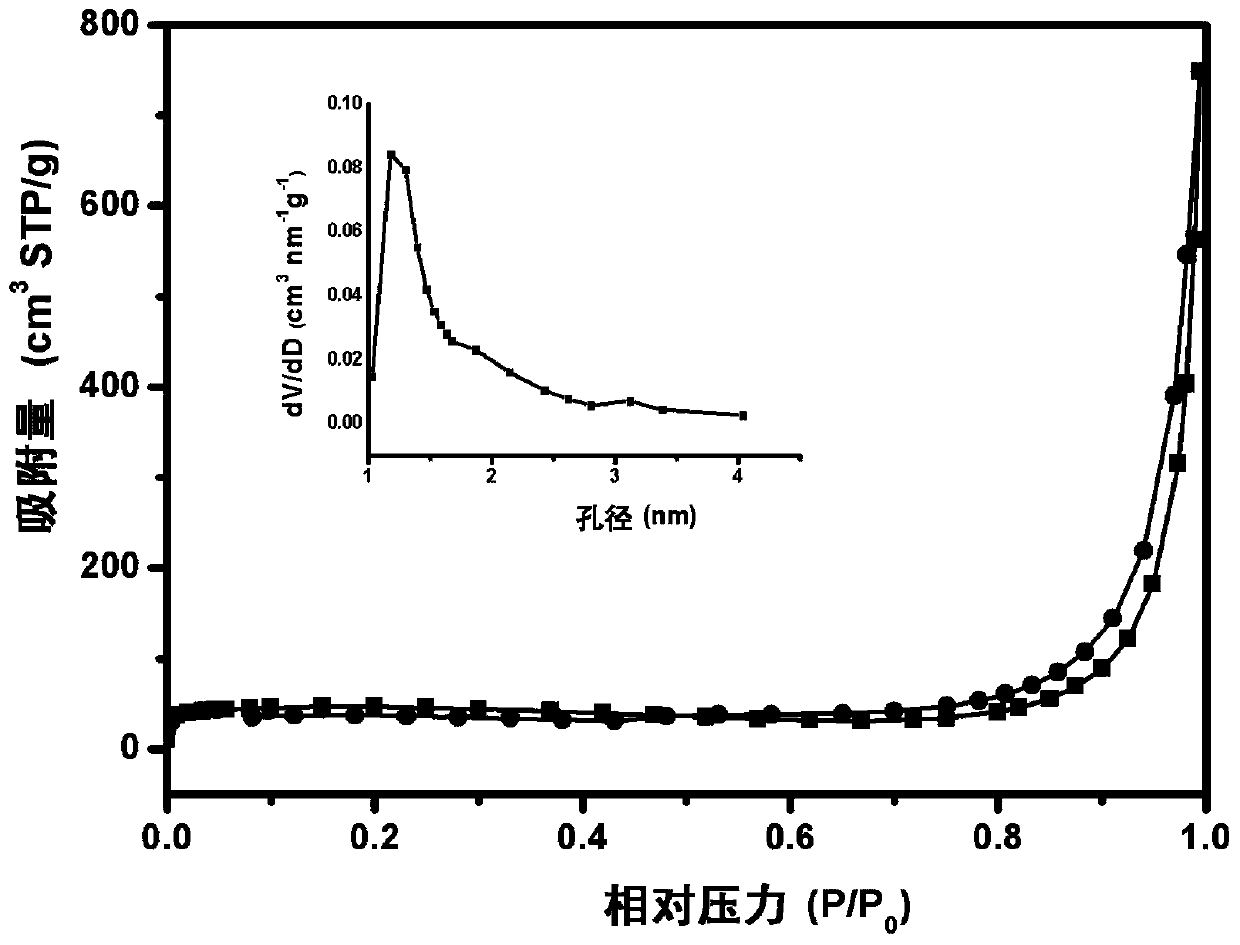

[0025] 2.5g melamine and 2.55g cyanuric acid were dissolved in 100mL and 50mL dimethyl sulfoxide respectively, after ultrasonic treatment to complete dissolution, it was mixed and stirred for 10 minutes to obtain a white precipitate. Subsequently, the mixture was centrifuged at 3000 rpm for 5 minutes to remove the solvent, and washed several times with ethanol. The resulting white powder was dried at 60°C overnight and calcined in a muffle furnace at 550°C for 4 hours at a heating rate of 5°C per minute. Curly light brown graphene carbon nitride nanosheets were obtained. Its microscopic appearance is as figure 2 b, with curled nanosheet structure, image 3 The nitrogen adsorption curves show that the prepared nanosheet structure has a high specific surface area and porous structure, and the photoelectrochemical and photocatalytic properties are as follows: Figure 5 , Image 6 It is shown that the porous nanosheets can improve the photoelectrochemical performance of the m...

example 2

[0027] Graphite carbon nitride / reduced graphene oxide composites were obtained by solvothermally combining porous graphitic carbon nitride nanosheets and graphene oxide. Add 200 mg of graphitic carbon nitride to 50 mL of dimethyl sulfoxide. Then, a certain amount of graphene oxide (such as 1.25%, 2.5%, 5%) obtained by the improved Hummers method was added to the graphite phase carbon nitride nanosheet solution, and ultrasonically dispersed for 1 hour. The mixed solution was then transferred to a Teflon-lined stainless steel autoclave (100 mL) and heated at 180°C for 12 hours. After cooling to room temperature, it was filtered and the prepared complex was dried at 60°C overnight. Figure 4 XPS curve of porous sulfur-doped graphite phase carbon nitride / reduced graphene oxide nanosheets, Figure 4 (d) The characteristic peak of sulfur appears, indicating that sulfur can be doped in graphene carbon nitride by DMSO solvothermal. combine Figure 5 Photoelectrochemical performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com