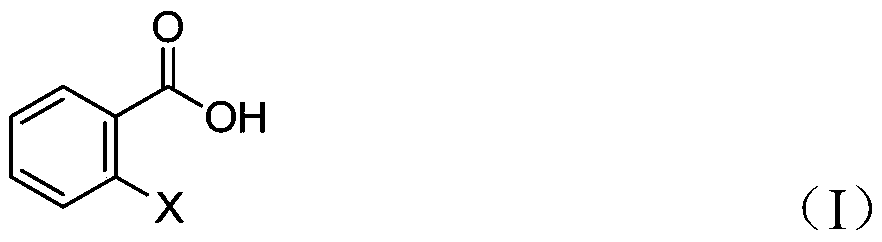

Synthesis method of 2-halogen-5-iodobenzoic acid

A technology of iodobenzoic acid and synthesis method, which is applied in the direction of chemical instruments and methods, carboxylate preparation, organic compound preparation, etc., can solve the problems of excessive three wastes, low economic benefit, unfavorable industrialization, etc., and achieve the improvement of product quality, The effect of reducing environmental pollution and cleaning production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 (comparative example 1)

[0032] In a four-neck flask equipped with a thermometer and agitator, add 15.6g of o-chlorobenzoic acid and dissolve it in 320.0g of 90% sulfuric acid, then add 3.8g of sodium periodate and 13.0g of iodine into the reaction solution, start stirring, and control the reaction temperature 25 ~ 30 ℃, heat preservation reaction for 1 hour, the reaction solution turns black, after the reaction of the raw materials is completed, the reaction solution is poured into cold sodium thiosulfate aqueous solution to quench, the reaction solution is spin-dried, filtered, the purity of the crude product is 65%, a Content 18%, b content 10%. Recrystallized with 46.8ml of methanol to obtain 12.6g of crude product. Yield 45%. 98.2% purity.

[0033] When adopting Tetrahedron, 60 (2004), when the reaction condition of 9113-9119 was used o-chlorobenzoic acid, the reaction solution was black, the product quality was poor, and there were many impurities...

Embodiment 2

[0035] In a four-necked flask equipped with a thermometer and an agitator, add 15.6g of o-chlorobenzoic acid to dissolve in 78.0g of sulfuric acid and 62.4g of DCM, then add 3.8g of sodium periodate and 13.0g of iodine into the reaction solution, start stirring, and control The reaction temperature is 25-30°C, and the heat preservation reaction is carried out for 1 hour. A purple solid is precipitated in the reaction solution. After the reaction of the raw materials is completed, the product content in the reaction solution is 88%, and the content of 3-iodo-2-halo-benzoic acid (a) is 8%. 3, 5-diiodo-2-halo-benzoic acid (b) content 2%. Pour the reaction solution into cold sodium thiosulfate aqueous solution to quench, spin the reaction solution to dryness, filter, and recrystallize with 46.8ml of methanol to obtain 19.3g of 2-chloro-5-iodobenzoic acid. Yield 68.6%, purity 99.1%. 1 H NMR (CDCl 3 ,400MHz), δ: 11.26(s,1H); 8.32(d,1H); 7.77(dd,1H); 7.23(d,1H).

Embodiment 3

[0037] In a four-necked flask equipped with a thermometer and agitator, add 15.6g of o-chlorobenzoic acid and dissolve in 78.0g of sulfuric acid and 62.4g of DCM, then add 4.0g of potassium iodate and 13.0g of iodine into the reaction solution, start stirring, and control the reaction The temperature is 25-30°C, heat preservation reaction for 1 hour, a purple solid is precipitated in the reaction solution, after the reaction of the raw materials, the product content in the reaction is 89%, the content of 3-iodo-2-halo-benzoic acid (a) is 9%, and the content of 3,5- The content of diiodo-2-halo-benzoic acid (b) is 0.5%. Pour the reaction solution into cold sodium thiosulfate aqueous solution to quench, spin the reaction solution to dryness, filter, and recrystallize with 46.8ml of methanol to obtain 19.6g of 2-chloro-5-iodobenzoic acid. Yield 69.6%, purity 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com