Low-temperature type artificial lawn filling rubber-plastic particles and preparation method thereof

A kind of artificial turf, low-temperature type technology, applied in the direction of coating, construction, reflection/signal coating, etc., can solve the problems of low refractive index, skin damage, agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

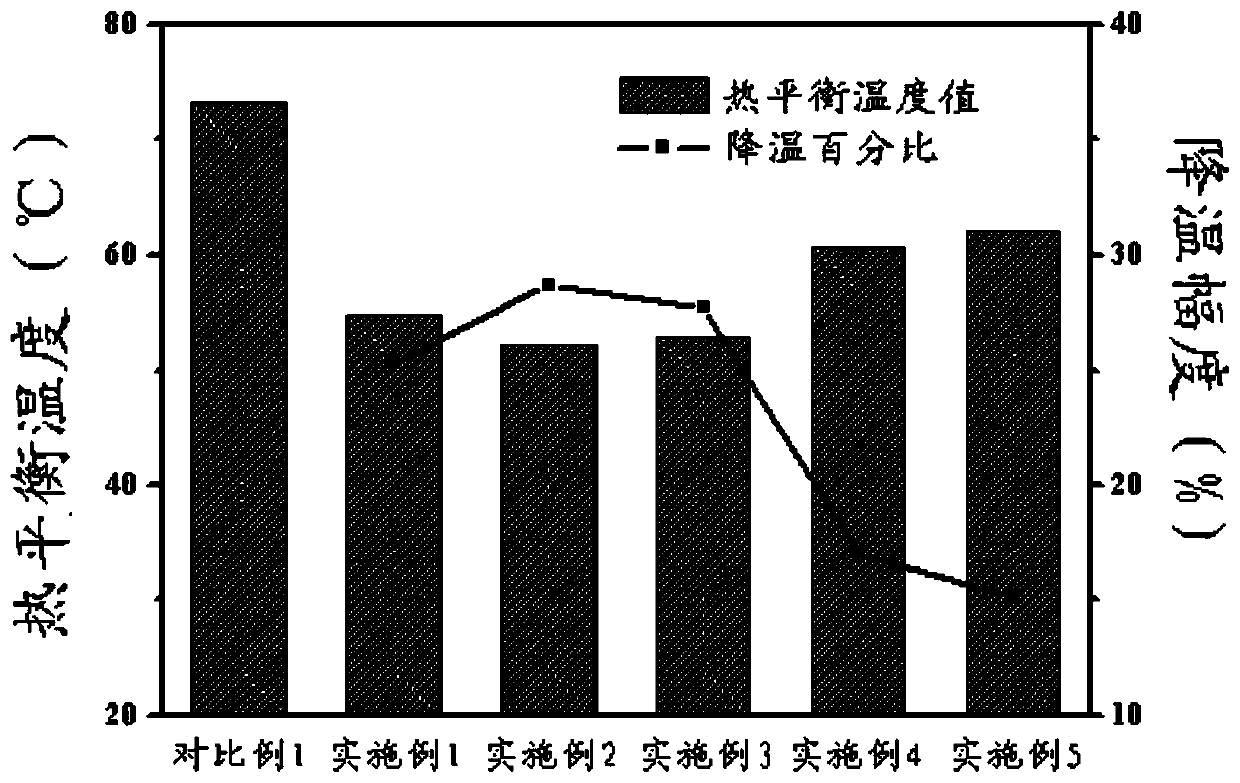

Embodiment 1

[0060] (1) Preparation of light / heat reflective coating:

[0061] S1) 40kg of diluent, 1.2kg of dispersant, 1.5kg of defoamer, 0.5kg of thickener were mechanically stirred for 20 minutes to mix evenly, and slowly added 8kg of heavy calcium carbonate (Jiangsu Hongda Environmental Protection Materials Co., Ltd., 325 mesh, spherical ) and 2.5kg TiO 2 Powder (Jiangsu Taibai Group Co., Ltd., rutile titanium dioxide ZR-940 + , 600 mesh) stirred to a uniformly dispersed suspension to obtain a premix;

[0062] S2) Take 20kg of premix, set the stirring speed to 240r / min, slowly add 6kg of epoxy resin emulsion, 0.2kg of color paste, and 0.5kg of adhesive, stir for 30min until the mixture has no precipitation, and set aside.

[0063] (2) Preparation of rubber and plastic particles for low-temperature artificial turf filling:

[0064] S1) POE 40kg, color masterbatch 1.5kg, UV light stabilizer 0.2kg, antioxidant 0.2kg, antistatic agent 0.2kg, dispersant 0.3kg, mineral oil 10kg, heavy ca...

Embodiment 2

[0068] (1) Preparation of light / heat reflective coating:

[0069] S1) 40kg of diluent, 1.2kg of dispersant, 1.5kg of defoamer, 0.5kg of thickener were mechanically stirred for 20 minutes to mix evenly, and slowly added 8kg of heavy calcium carbonate (Jiangsu Hongda Environmental Protection Materials Co., Ltd., 325 mesh) and 2.5kg TiO2 2 Powder (Dongjia Fanhua Chemical Technology Co., Ltd., rutile titanium dioxide IR-1000, 800 mesh) was stirred to a uniformly dispersed suspension to obtain a premix;

[0070] S2) Take 20kg of premix, set the stirring speed to 240r / min, slowly add 6kg of epoxy resin emulsion, 0.2kg of color paste, and 0.5kg of adhesive, stir for 30min until the mixture has no precipitation, and set aside.

[0071] (2) Preparation of rubber and plastic particles for low-temperature artificial turf filling:

[0072] S1) POE 40kg, color masterbatch 1.5kg, UV light stabilizer 0.2kg, antioxidant 0.2kg, antistatic agent 0.2kg, dispersant 0.3kg, mineral oil 10kg, heav...

Embodiment 3

[0076] (1) Preparation of light / heat reflective coating:

[0077] S1) 40kg of diluent, 1.2kg of dispersant, 1.5kg of defoamer, 0.5kg of thickener were mechanically stirred for 20 minutes to mix evenly, and slowly added 8kg of heavy calcium carbonate (Jiangsu Hongda Environmental Protection Materials Co., Ltd., 325 mesh) and 2.5kg BN powder (Suzhou Napo Material Technology Co., Ltd., hexagonal boron nitride, 2000 mesh) was stirred to a uniformly dispersed suspension to obtain a premix;

[0078]S2) Take 20kg of premix, set the stirring speed to 240r / min, slowly add 6kg of epoxy resin emulsion, 0.2kg of color paste, and 0.5kg of adhesive, stir for 30min until the mixture has no precipitation, and set aside.

[0079] (2) Preparation of rubber and plastic particles for low-temperature artificial turf filling:

[0080] S1) Put 40kg of POE, 1.5kg of color masterbatch, 0.2kg of UV stabilizer, 0.2kg of antioxidant, 0.2kg of antistatic agent, 0.3kg of dispersant, 10kg of mineral oil, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com