Diamond coating cutter with microstructural cooling function suitable for titanium alloy processing

A diamond coating and titanium alloy technology, which is applied in metal processing equipment, metal material coating technology, metal processing machinery parts, etc., can solve problems affecting tool life, reduce consumption, improve coating adhesion, and improve cooling effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and embodiments.

[0026] Such as Figure 1-5 Shown.

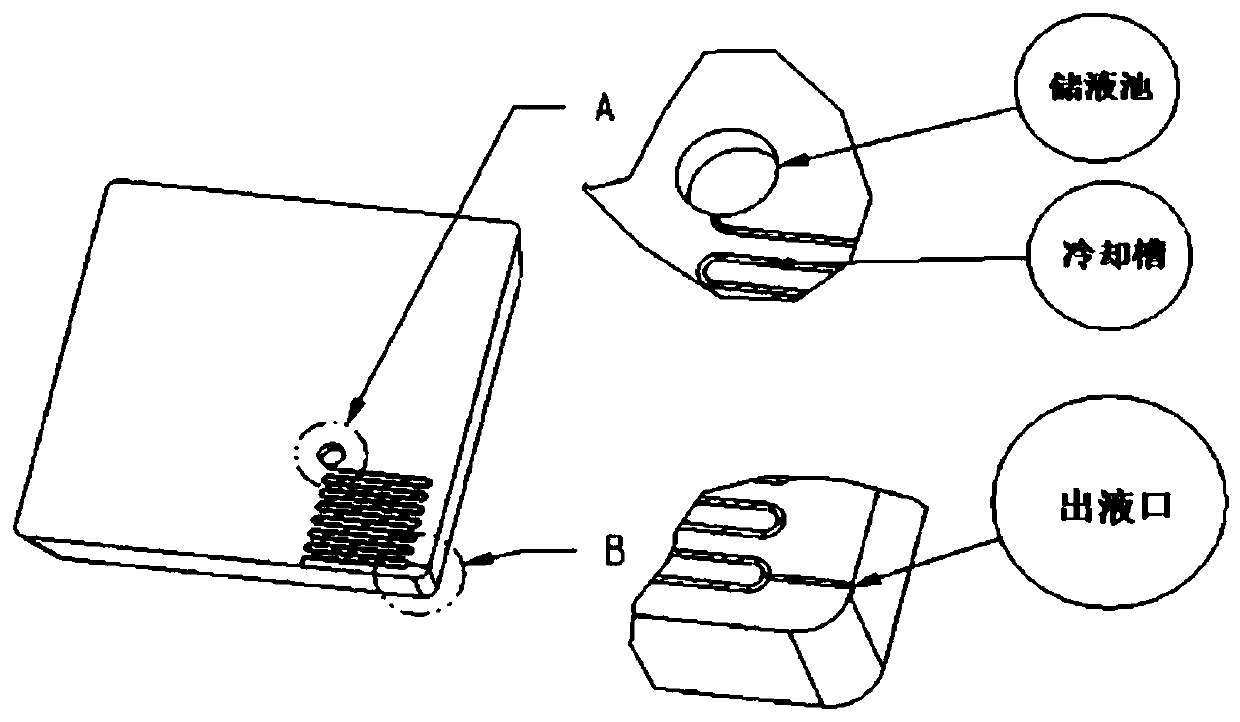

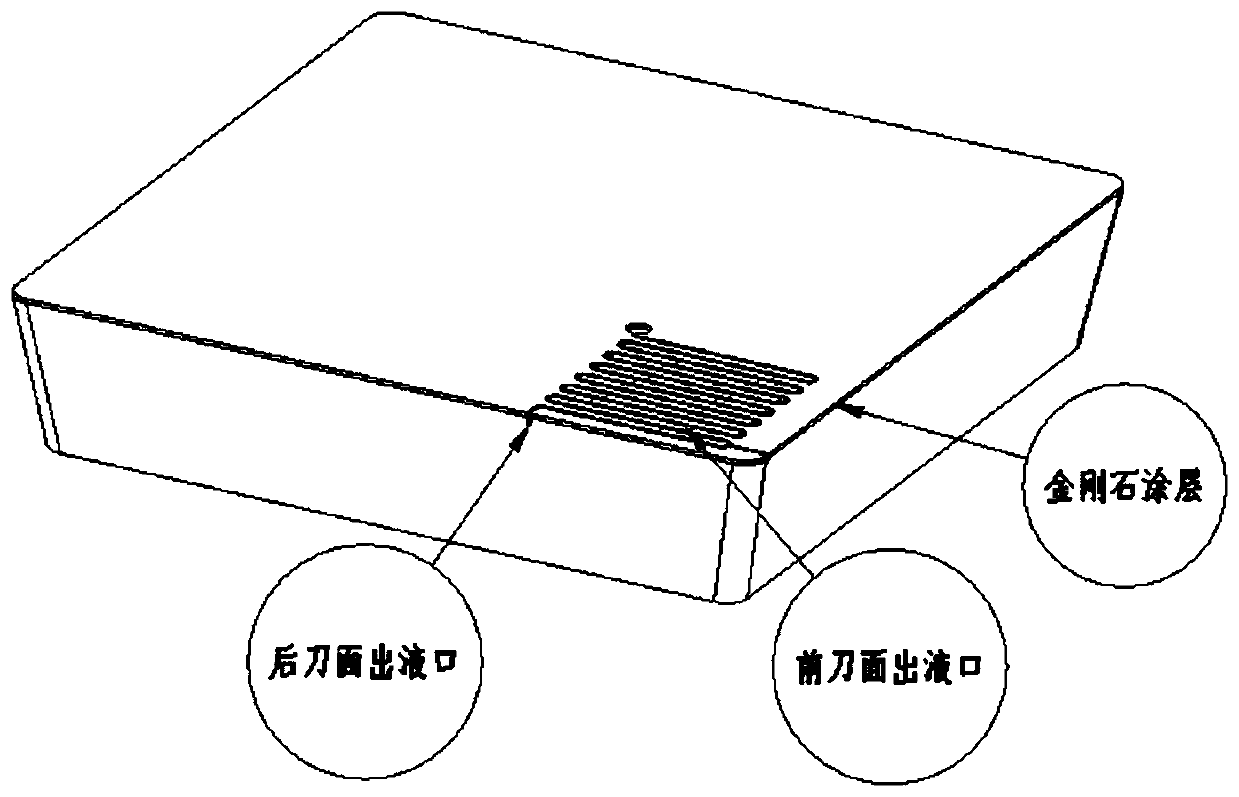

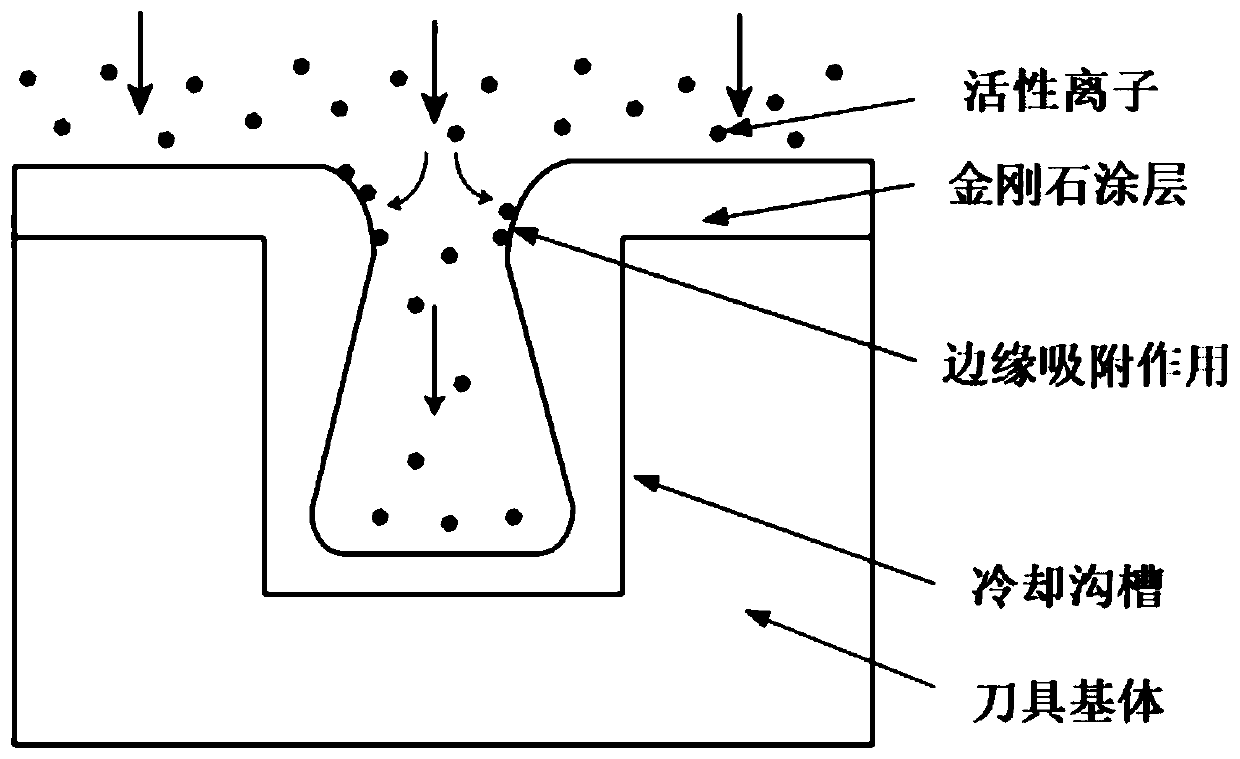

[0027] A diamond-coated tool with micro-structure cooling function suitable for titanium alloy processing. The tool tip and the crescent crater area are prepared with micro-textures, such as figure 1 , 2 As shown, a diamond coating is deposited on the micrograin. The micrograin includes a reservoir, a cooling tank, and a cutting fluid outlet; the reservoir is connected to at least one cooling tank, and the cooling tanks communicate with each other. The outlet is arranged on the front and rear knife surfaces and communicates with the cooling groove; the cooling groove is a bag-shaped pipe structure with a narrow upper and a wide lower part, such as image 3 , 4 As shown. It is prepared using the following steps:

[0028] First, prepare the tool matrix and clean it with an ultrasonic cleaning machine;

[0029] Secondly, prepare diamond po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com