Method and system for recycling graphene waste sulfuric acid

A technology of waste sulfuric acid and graphene, applied in the field of resources and environment, can solve the problems of no resource utilization, etc., and achieve the effect of low cost, less investment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

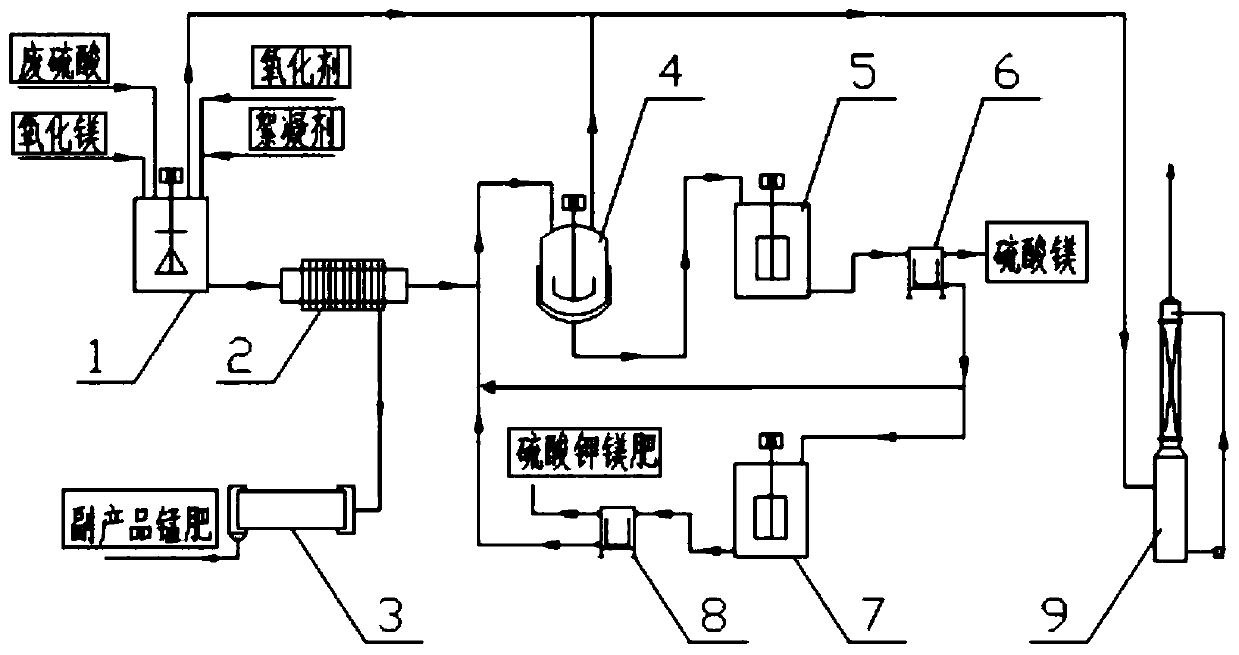

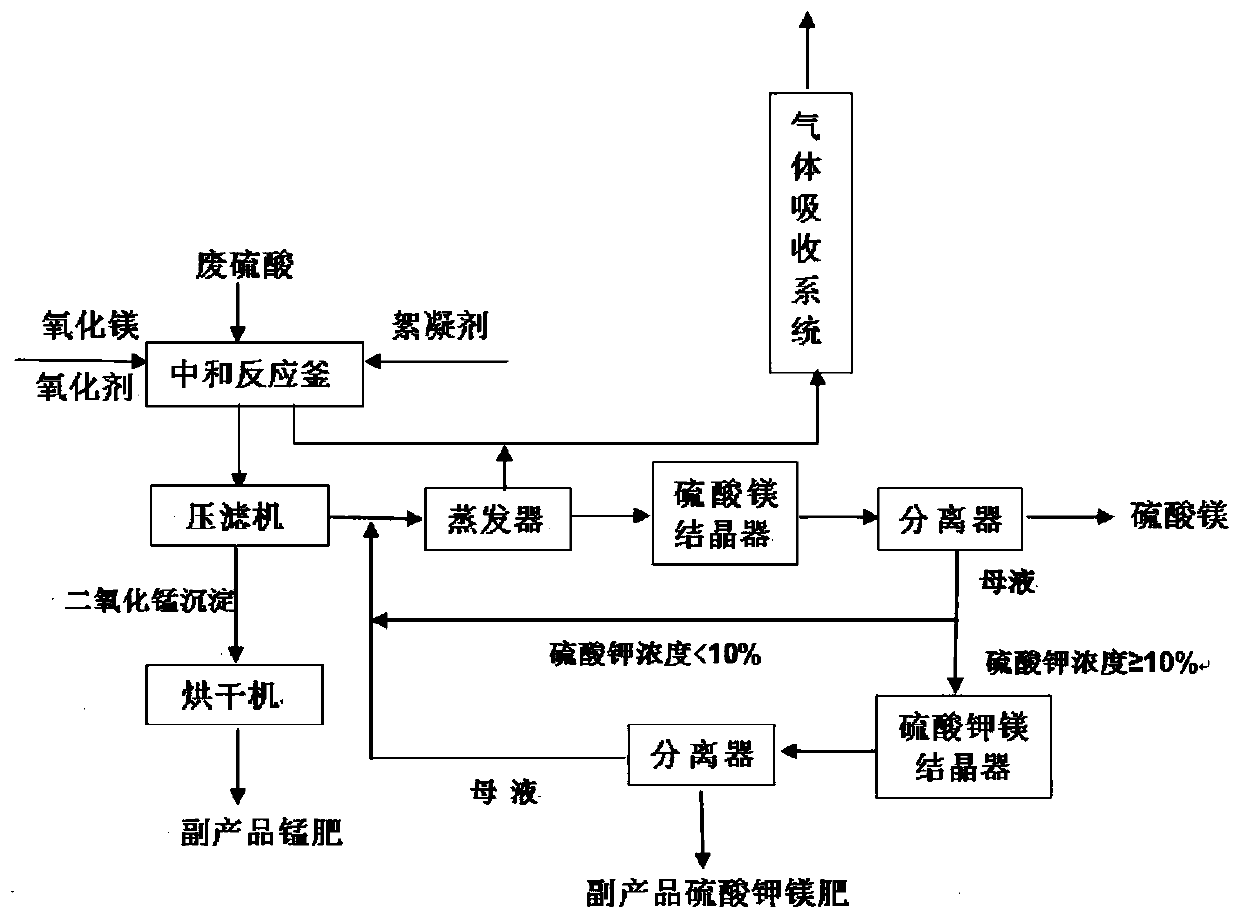

Method used

Image

Examples

Embodiment 1

[0080] (1) open reactor and stir, adding sulfuric acid mass content by sulfuric acid metering tank is 40% graphene waste sulfuric acid 1000kg and 90% light-burning magnesium oxide 182kg, until pH value reaches 7, temperature of reaction keeps 30 minutes at 90 DEG C;

[0081] (2) the solution of step (1) adds the hydrogen peroxide of 6.5kg mass concentration 30%, oxidizes divalent manganese ion (waste manganese ion content is 0.3%), generates manganese dioxide precipitation; After 1 hour of reaction, add 1kg polysulfuric acid Aluminum flocculant, filtering and separating manganese dioxide precipitate, and drying the precipitate to obtain 5kg of manganese fertilizer (manganese mass content is 60%);

[0082] (3) the filtrate from step (2) is mainly magnesium sulfate and a small amount of potassium sulfate solution (waste acid contains potassium ion 0.4%), through circulating concentration and cooling crystallization, obtain 950kg of magnesium sulfate that meets HG / T 2680-2017 tech...

Embodiment 2

[0086] (1) open reactor and stir, adding sulfuric acid mass content by sulfuric acid metering tank is 50% graphene waste sulfuric acid 1000kg and 90% light-burning magnesium oxide 227kg, until pH value reaches 6, and temperature of reaction keeps 30 minutes at 90 DEG C;

[0087] (2) the solution of step (1) adds 7.2kg of sodium hypochlorite, oxidizes divalent manganese ions (the content of waste manganese ions is 0.5%), and generates manganese dioxide precipitation; after 1 hour of reaction, 1.2kg of polyaluminum sulfate flocculant is added, Filter and separate manganese dioxide precipitate, and the precipitate is dried to obtain 8kg of manganese fertilizer (manganese content is 60%);

[0088] (3) the filtrate from step (2) is mainly magnesium sulfate and a small amount of potassium sulfate solution (waste acid contains potassium ion 0.2%), through cyclic concentration and cooling crystallization, obtain 1225kg of magnesium sulfate that meets the technical requirements of HG / T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com