Application of liquid phase stripped niobium disulfide nano sheet

A niobium disulfide, liquid phase exfoliation technology, applied in nanotechnology, niobium compounds, inorganic chemistry and other directions, can solve the problems of low feasibility, difficult operation, long time consumption, etc., to achieve good electrochemical performance and stability, High controllability and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

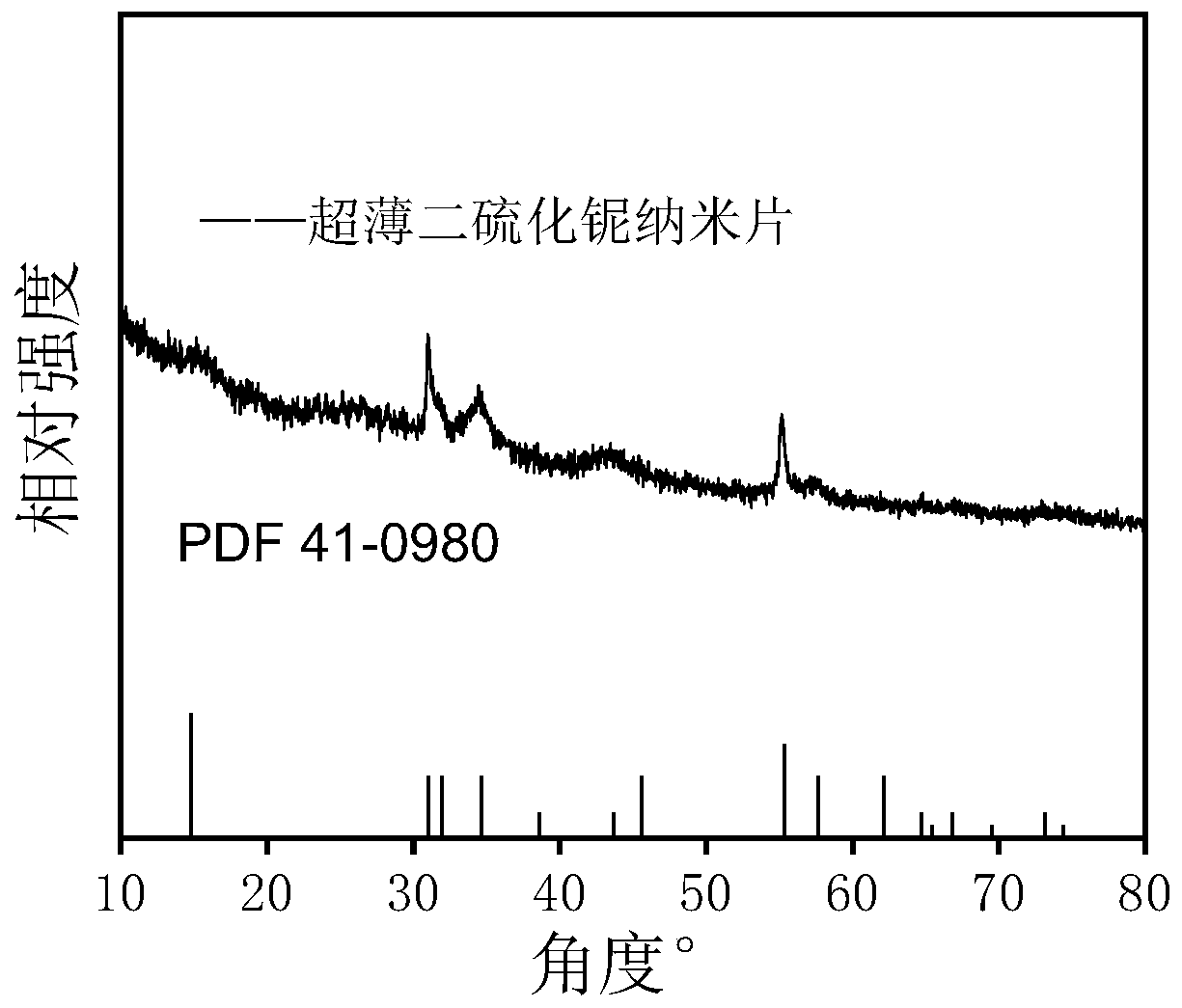

[0036] 1. Preparation of niobium disulfide powder

[0037] (1) Sulfur powder and niobium powder are mixed according to the stoichiometric ratio, and after fully grinding, the mixture is sealed in a vacuum quartz glass tube;

[0038] (2) Use a tube furnace to heat the mixture from room temperature, the heating temperature is 1050°C, the holding time is 10h, the heating rate is 5°C / min, and the temperature is naturally lowered after the heating is completed to obtain niobium disulfide powder.

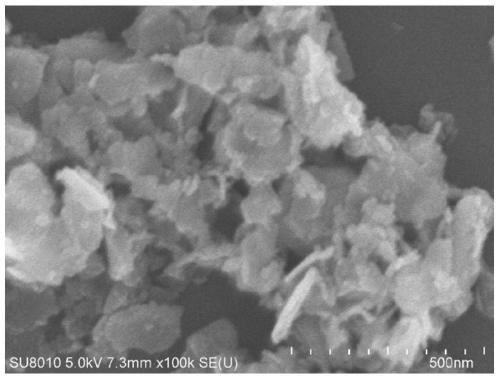

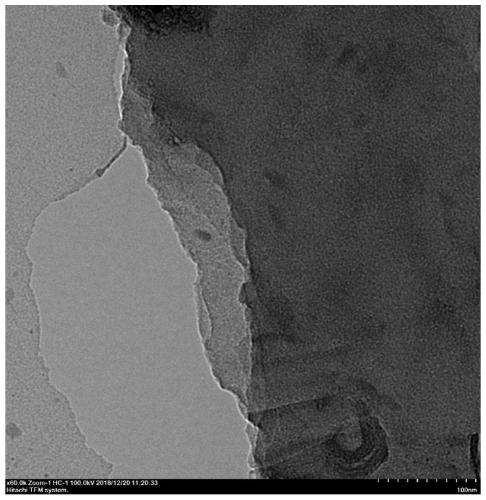

[0039] 2. Liquid phase exfoliation

[0040] Disperse niobium disulfide powder into N-methylpyrrolidone, and perform ultrasonic crushing treatment with an ultrasonic crusher. The ultrasonic power is 350W, and the ultrasonic time is 10h, in which the ultrasonic works for 1 s and pauses for 0.5 s.

[0041] 3. Centrifugation and Washing

[0042] (1) Centrifuge the niobium disulfide flakes and the N-methylpyrrolidone dispersion, the centrifugal speed is 2000rpm, the centrifugation time is 3...

Embodiment 2

[0059] The liquid phase exfoliation of niobium disulfide nanosheets was prepared as shown in Example 1, except that the dispersion solvent used in the ultrasonic process was isopropanol, and other conditions were the same. When the prepared niobium disulfide nanosheets are used as the cathode catalyst in electrochemical nitrogen fixation in acidic electrolyte, the ammonia production rate is 27.61 μg h when the applied voltage is -0.5V (vs.RHE). -1 mg -1 cat , the corresponding Faraday efficiency is 8.57%;

Embodiment 3

[0061] The liquid phase exfoliation of niobium disulfide nanosheets was prepared as shown in Example 1, except that the dispersion solvent used in the ultrasonic process was dimethyl sulfoxide, and other conditions were the same. When the prepared niobium disulfide nanosheets are used as the cathode catalyst in electrochemical nitrogen fixation in acidic electrolyte, the ammonia production rate is 25.84μg h when the applied voltage is -0.5V (vs.RHE). -1 mg -1 cat ., the corresponding Faraday efficiency is 7.46%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com