A kind of preparation method of hydrangea cellulose facial mask

A hydrangea and cellulose technology, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of low degree of polymerization of biological cellulose, low degree of cellulose forming, and fiber bundle network Short and other problems, to achieve the effect of improving carding performance, increasing moisture content, and continuous fiber bundles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

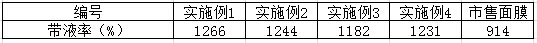

Examples

Embodiment 1

[0026] Wash the fresh hydrangea with clean water to remove impurities such as silt, and remove its roots at the same time, cut into pieces appropriately, put them in a drying oven at 40°C to dry, dry to constant weight, put them into a pulverizer, and crush them. The hydrangea powder is passed through a 40-mesh sieve, put into a clean and dry beaker, and stored dry until use. Accurately weigh 100 g of hydrangea fruiting body dry powder, add 1000ml of water, and extract by ultrasonic for 1 min. The ultrasonic power is 200W, and the extraction temperature is set to Suction filter the polysaccharide extract at 50°C to obtain the filter cake and filtrate, retain the filtrate, and use the filter cake to proceed to the next step;

[0027] Soak the filter cake with 500ml of ethyl acetate at room temperature for 3 hours, then wash the remaining organic solvent with 1000ml of distilled water, filter it with suction, and dry it to obtain a degreased sample. Add 20% dilute sulfuric acid s...

Embodiment 2

[0031]Wash the fresh hydrangea with clean water to remove impurities such as silt, and remove its roots at the same time, cut into pieces appropriately, put them in a drying oven at 40°C to dry, dry to constant weight, put them into a pulverizer, and crush them. The hydrangea powder is passed through a 40-mesh sieve, put into a clean and dry beaker, and stored dry until use. Accurately weigh 100 g of hydrangea fruiting body dry powder, add 1000ml of water, and extract by ultrasonic for 3 minutes. The ultrasonic power is 100W, and the extraction temperature is set to At 90°C, suction filter the polysaccharide extract to obtain a filter cake and filtrate, retain the filtrate, and use the filter cake to proceed to the next step;

[0032] Soak the filter cake with 500ml of ethyl acetate at room temperature for 3 hours, then wash the residual organic solvent with 1000ml of distilled water, filter it with suction, and dry it to obtain a degreased sample. Hydrolyze in a water bath fo...

Embodiment 3

[0036] Wash the fresh hydrangea with clean water to remove impurities such as silt, and remove its roots at the same time, cut into pieces appropriately, put them in a drying oven at 40°C to dry, dry to constant weight, put them into a pulverizer, and crush them. The hydrangea powder is passed through a 40-mesh sieve, put into a clean and dry beaker, and stored dry until use. Accurately weigh 100 g of hydrangea fruiting body dry powder, add 1000ml of water, and extract by ultrasonic for 3 minutes. The ultrasonic power is 150W, and the extraction temperature is set to At 70°C, suction filter the polysaccharide extract to obtain a filter cake and filtrate, retain the filtrate, and use the filter cake to proceed to the next step;

[0037] Soak the filter cake with 500ml of ethyl acetate at room temperature for 3 hours, then wash the residual organic solvent with 1000ml of distilled water, filter it with suction, and dry it to obtain a degreased sample. Add 10% dilute sulfuric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com