Metal monoatomic catalyst loaded by flexible carbon-based carrier and preparation method and application of catalyst

A carbon-based carrier, metal-loaded technology, applied in the field of electrocatalysis, can solve the problems of limiting large-scale practical application, increasing electrode contact resistance, low mechanical strength, etc., and achieving uniform dispersion of single atoms, reduced contact resistance, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

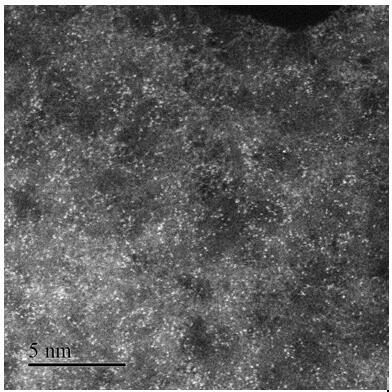

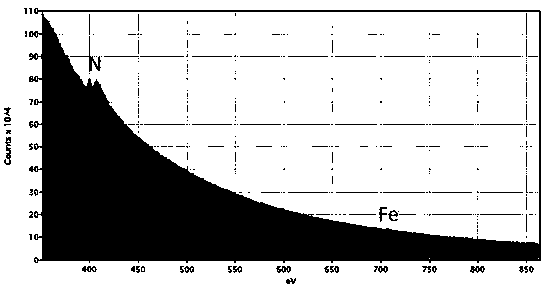

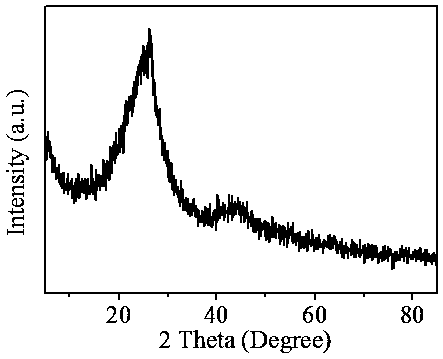

[0054] (1) Weigh 50 mg of graphene, 3 g of melamine and 0.5 g of porphyrin iron, and disperse them in 100 ml of anhydrous methanol, sonicate for 30 min, then stir at room temperature for 12 h to obtain a uniform mixture Slurry; (2) Choose flexible graphene film as the substrate, uniformly load the prepared homogeneous slurry on both surfaces of the graphene film by scraping method, and the loading thickness on both sides is 35 mm, and then place it Dry naturally at room temperature; (3) Place the dried composite membrane in step (2) in a high-purity argon atmosphere, and perform slow multi-step high-temperature pyrolysis treatment, and raise the temperature to 180 °C at a rate of 2 °C / min Hold for 2 hours, then raise the temperature to 360°C at a rate of 2°C / min and hold for 2 hours, then raise the temperature to 800°C at a rate of 2°C / min and hold for 2 hours, and finally cool down to room temperature at a rate of 2°C / min, the whole gas flow rate 10 ml / min; (4) Soak the heat-...

Embodiment 2

[0057] (1) Weigh 40 mg of graphene, 5 g of urea and 0.45 g of porphyrin zinc, and disperse the three in 300 ml of ultrapure water, ultrasonicate for 50 min, and then stir at room temperature for 12 h to obtain a uniform mixture Slurry; (2) Choose flexible carbon fiber cloth as the base, soak the carbon fiber cloth into the prepared homogeneous slurry by the soaking method, soak for 30 min, take it out and vacuum dry it in an oven at 70 °C for 2 h, and then place it Wet again, repeated 5 times, and dried in vacuum; (3) Place the dried composite film in step (2) in a high-purity argon atmosphere, and perform slow multi-step high-temperature pyrolysis treatment at a rate of 3 ℃ / min The temperature was raised to 200°C for 1.5 h, then raised to 380°C at a rate of 3°C / min and held for 2 h, then raised to 850°C at a rate of 3°C / min and held for 2 h, and finally lowered to At room temperature, the whole gas flow rate is 9 ml / min; (4) Soak the heat-treated carbon fiber composite cloth ...

Embodiment 3

[0059] (1) Weigh 45 mg of graphene, 4.5 g of dicyandiamide and 0.6 g of copper phthalocyanine, and disperse the three in 400 ml of anhydrous methanol, ultrasonicate for 60 min, and then stir at room temperature for 15 h to obtain a uniform (2) Choose flexible bamboo fiber cloth as the substrate, and load the prepared homogeneous slurry on the bamboo fiber cloth by spin coating method, the spin coating thickness is 30 mm, and the spin coating speed is 500 rpm, and then set Vacuum-dried in an oven at 90 °C for 10 h, repeated 3 times, and then vacuum-dried; (3) The composite film dried in step (2) was placed in a high-purity nitrogen atmosphere, and it was subjected to slow multi-step high-temperature pyrolysis treatment, The temperature was raised to 150°C at a rate of 5°C / min and kept for 1.5 h, then raised to 350°C at a rate of 5°C / min and held for 1.5 h, then raised to 780°C at a rate of 5°C / min and held for 2 h, and finally heated at 5°C / min down to room temperature, the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com