Preparation method of composite copper-based SCR molecular sieve catalyst

A molecular sieve and catalyst technology, applied in the field of the preparation of composite copper-based SCR molecular sieve catalyst, can solve the problems of environmental pollution, metal loss, poor NOx removal effect, etc., achieve high catalytic conversion efficiency, enhance thermal stability, and improve adsorption and storage effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of a kind of composite copper-based SCR molecular sieve catalyst that the present invention proposes comprises the following steps:

[0030] S1. Mix N,N,N-trimethyl-1-adamantyl ammonium hydroxide with water, stir, then add aluminum sulfate, stir, adjust the pH value, then add silica sol, stir to obtain the initial gel mixture ;

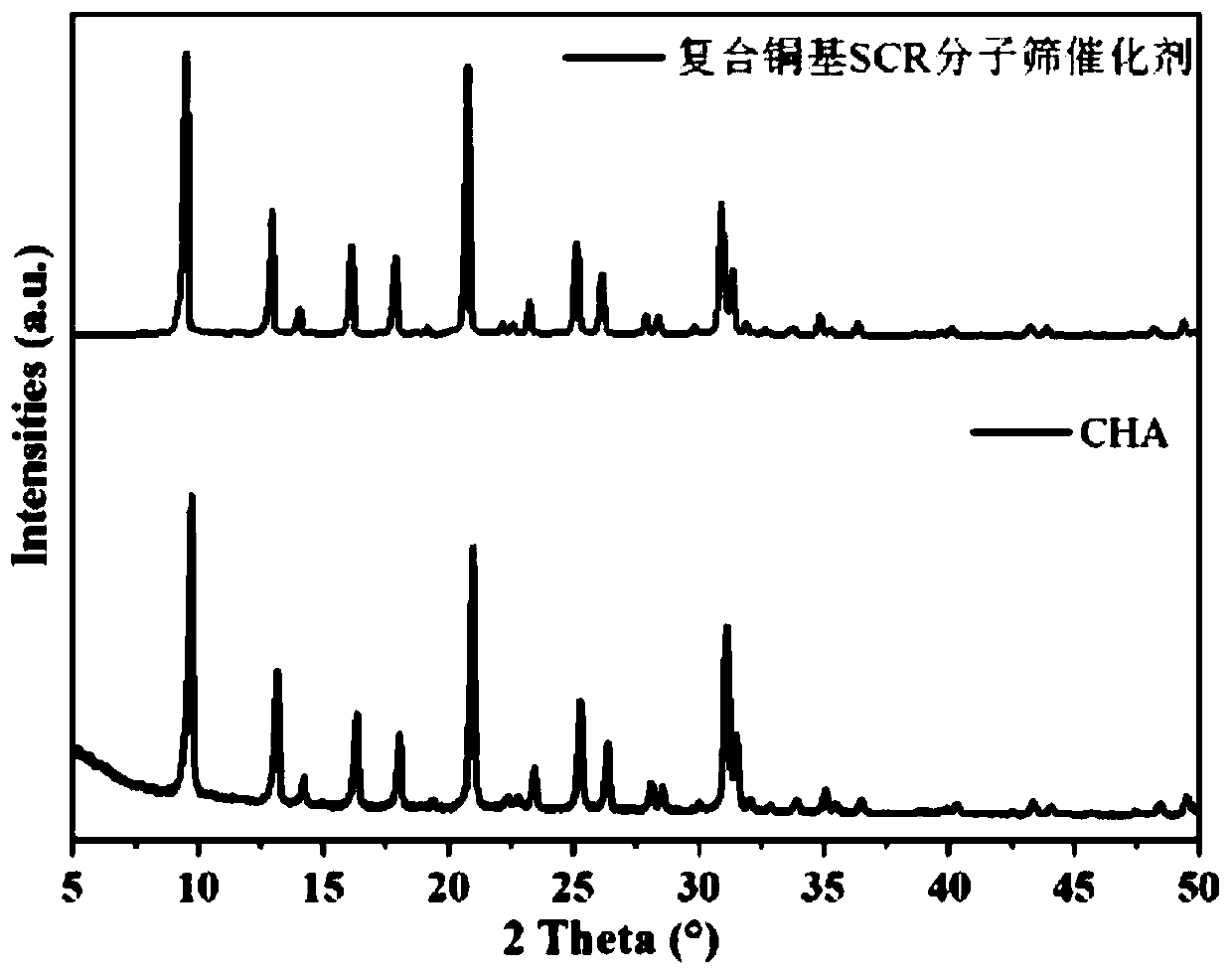

[0031] S2. Constant temperature crystallization of the initial gel mixture, cooling, washing, drying, and roasting to obtain CHA-type molecular sieves;

[0032] S3. Using CHA-type molecular sieve as a carrier, impregnating manganese nitrate, cerium nitrate, palladium nitrate and copper acetate step by step, and then drying to obtain a composite copper-based SCR molecular sieve catalyst.

Embodiment 2

[0034] The preparation method of a kind of composite copper-based SCR molecular sieve catalyst that the present invention proposes comprises the following steps:

[0035] S1. Mix N,N,N-trimethyl-1-adamantyl ammonium hydroxide with water, stir for 8 minutes, then add aluminum sulfate, stir until the aluminum sulfate is fully dissolved, adjust the pH of the system to 11 with sodium hydroxide , then add silica sol, and stir for 5 minutes to obtain the initial gel mixture; wherein, the molar ratio between N,N,N-trimethyl-1-adamantyl ammonium hydroxide, water, aluminum sulfate, and silica sol is 0.08 :16:0.03:0.8;

[0036] S2. The initial gel mixture was crystallized at a constant temperature of 155°C for 4.5 days, cooled, filtered and washed with deionized water, dried at 95°C for 11 hours to obtain the original powder of SSZ-13 molecular sieve, and then roasted at 590°C for 6.5 hours to obtain CHA type molecular sieve;

[0037] S3. Using CHA molecular sieve as a carrier, impreg...

Embodiment 3

[0039] The preparation method of a kind of composite copper-based SCR molecular sieve catalyst that the present invention proposes comprises the following steps:

[0040] S1. Mix N,N,N-trimethyl-1-adamantyl ammonium hydroxide with water, stir for 5 minutes, then add aluminum sulfate, stir until the aluminum sulfate is fully dissolved, adjust the pH of the system to 12 with sodium hydroxide , then add silica sol, and stir for 5 minutes to obtain an initial gel mixture; wherein, the molar ratio between N,N,N-trimethyl-1-adamantyl ammonium hydroxide, water, aluminum sulfate, and silica sol is 0.1 :20:0.04:1;

[0041] S2. The initial gel mixture was crystallized at a constant temperature of 160°C for 4 days, cooled, washed with deionized water, and dried at 90°C for 12 hours to obtain the original powder of SSZ-13 molecular sieve, which was then roasted at 600°C for 6 hours to obtain a CHA type molecular sieve;

[0042]S3. Using CHA molecular sieve as a carrier, impregnate mangan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com