Nano composite hydrogen storage material and preparation method thereof

A hydrogen storage material and nano-composite technology, applied in chemical instruments and methods, metal material coating technology, hydrogen, etc., can solve the problems of unsuitable commercial practical conditions, unfavorable portability, difficult control, etc., and achieve the potential of improving commercial application , reliable synthesis method, high mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

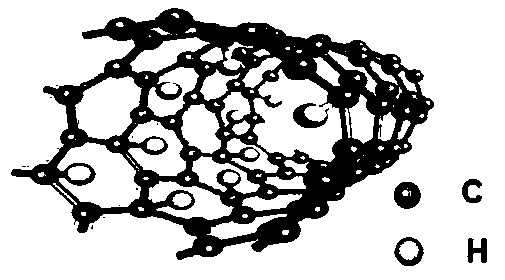

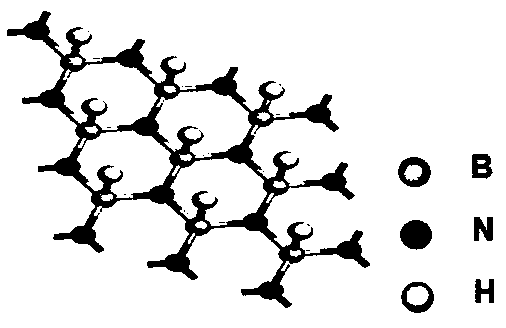

[0046] Example 1 h-BN / CNT-30-1 (h-BN / CNT-X-Y, where X represents the chemical vapor deposition time, Y represents the Ni / h-BN mass ratio:

[0047] (1) Preparation of functionalized two-dimensional hexagonal boron nitride powder: put two-dimensional hexagonal boron nitride powder into concentrated HNO 3 In the solution, reflux at 140° C. for 8 hours, cool to room temperature, wash with deionized water until neutral and dry to obtain functionalized two-dimensional hexagonal boron nitride nanosheets.

[0048] (2) Preparation of functionalized two-dimensional hexagonal boron nitride supported nickel catalyst: 0.5 g functionalized two-dimensional hexagonal boron nitride nanosheet and 2.4661 g Ni(NO 3 ) 2 ·6H 2 O (the mass ratio of nickel to two-dimensional hexagonal boron nitride is 1:1) was added to 35mL of acetone reagent, ultrasonically mixed and then dried; the dried powder was calcined in an argon atmosphere at 450°C for 4h , and then reduced in a hydrogen atmosphere at 460...

Embodiment 2

[0054] Example 2 h-BN / CNT-15-1

[0055] (1) Compared with Example 1 in this example, only the vapor deposition time is changed to 15 minutes.

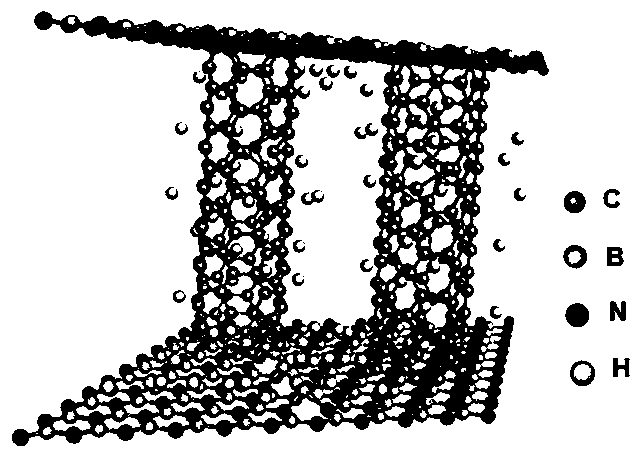

[0056] Figure 6 For h-BN / CNT-15-1, with Figure 5 h-BN / CNT-30-1 is significantly shorter than carbon nanotubes.

[0057] The h-BN / CNT-15-1 prepared in this example reaches saturated hydrogen absorption within 20 minutes, reaches the maximum hydrogen absorption of 8.3wt% at 300K, and releases 7.9wt% of hydrogen within 30 minutes at 500K.

Embodiment 3

[0058] Example 3 h-BN / CNT-30-3

[0059] (1) Compared with Example 1, this example only changes the mass ratio of nickel to two-dimensional hexagonal boron nitride, and Ni(NO 3 ) 2 ·6H 2 The amount of O was changed to 7.3983g (the mass ratio of nickel to two-dimensional hexagonal boron nitride was 3:1).

[0060] Figure 7 For h-BN / CNT-30-3, with Figure 5 The forest of h-BN / CNT-30-1 is obviously denser than that of CNT.

[0061] The h-BN / CNT-30-3 prepared in this example reaches saturated hydrogen absorption within 20 minutes, reaches the maximum hydrogen absorption of 11wt% at 300K, and releases 10.7wt% of hydrogen within 30 minutes at 500K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com