Oilfield produced water microorganism water quality modification treatment method

A treatment method and technology for produced water, applied in biological water/sewage treatment, mining wastewater treatment, special compound water treatment, etc., which can solve the damage characteristics, pay little attention, and exacerbate the high salinity produced water treatment and reinjection system Corrosion and other problems, to achieve the effect of increasing fluidity and improving oil recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

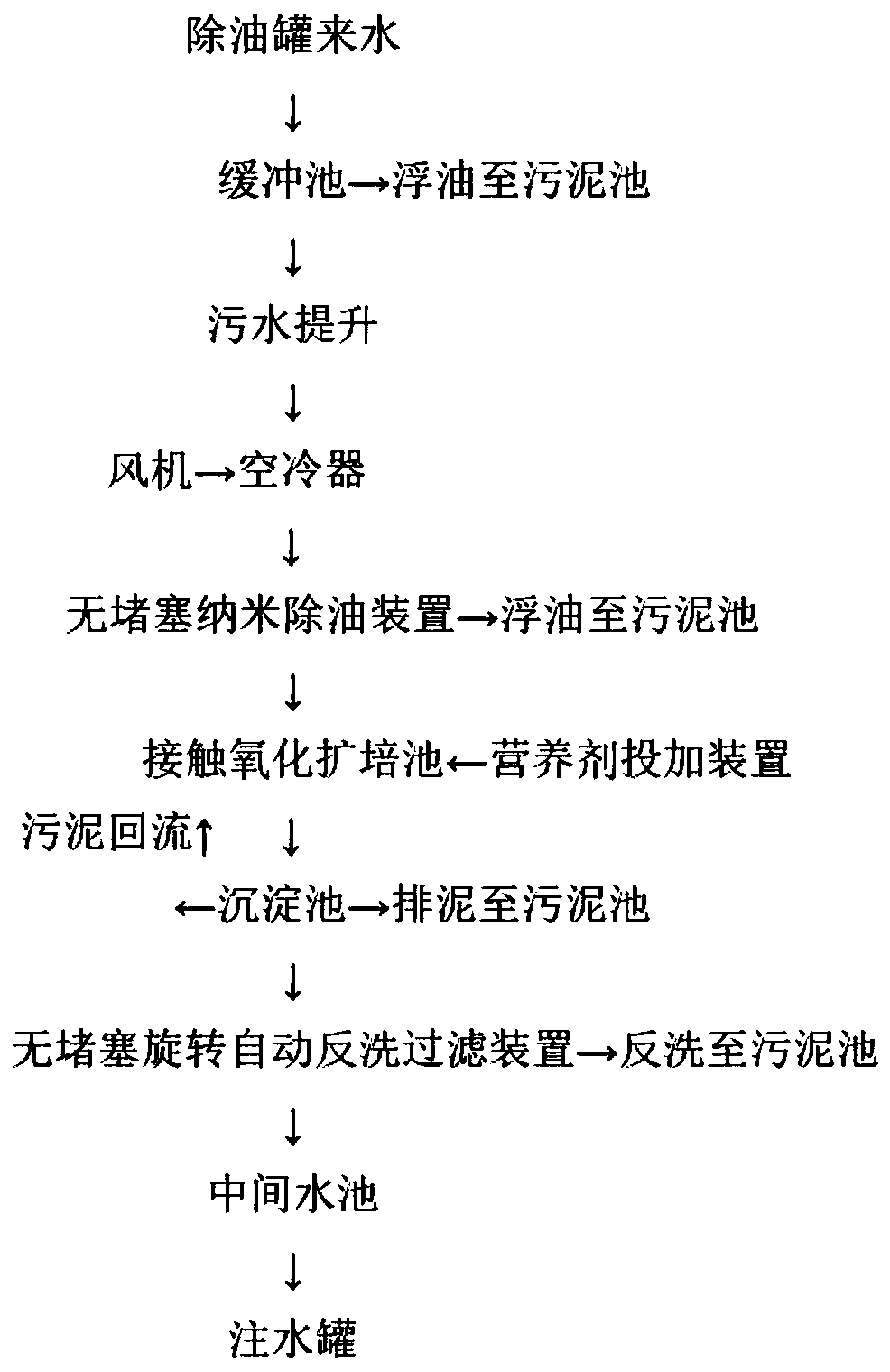

[0029] like figure 1 and figure 2 As shown, the present invention provides the present invention provides a kind of microbial water quality modification treatment method of oilfield produced water, comprises the steps:

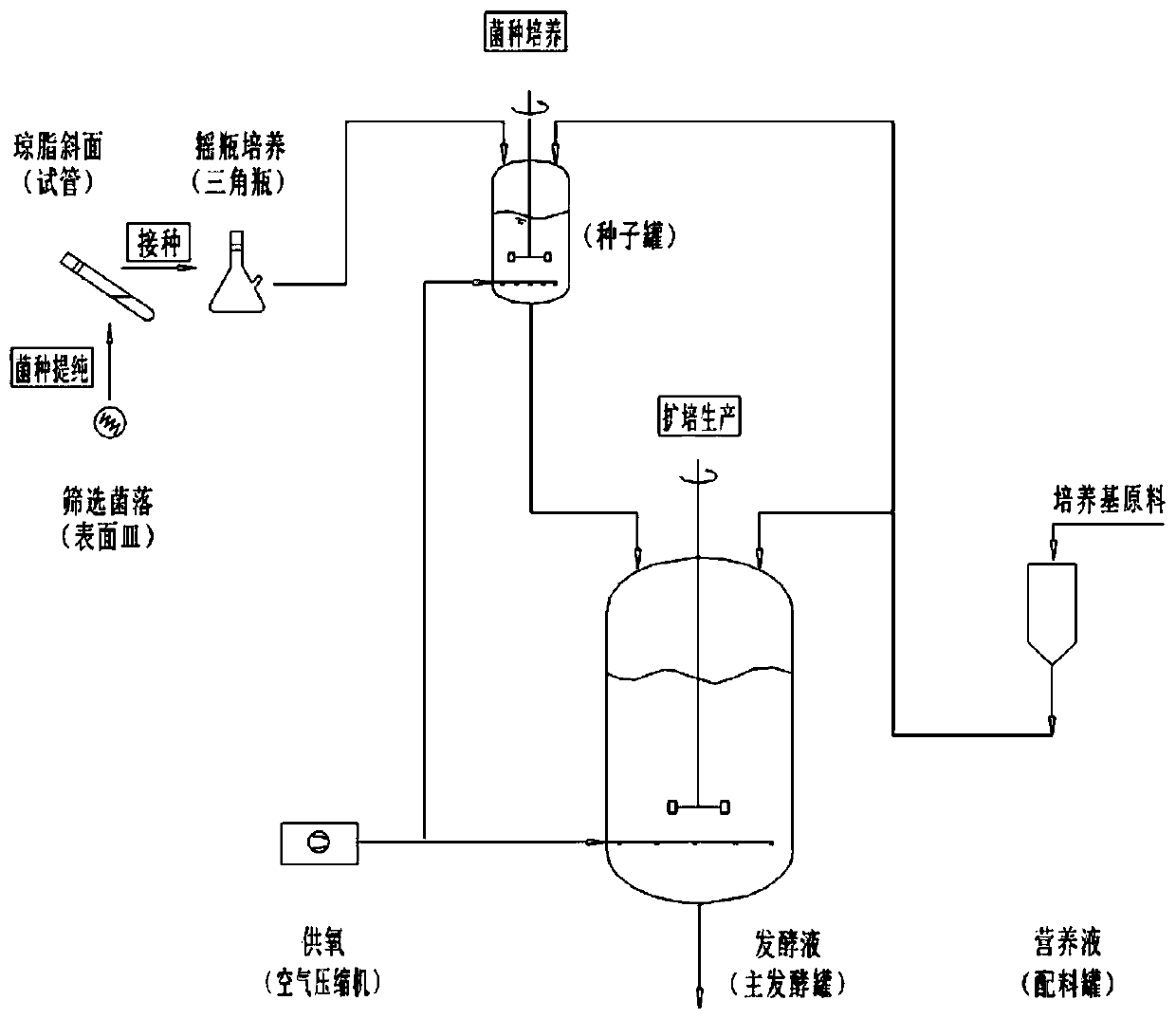

[0030] S1: Breeding strains:

[0031] Collect wellhead crude oil, oily sludge at wellsite, and oily sludge from oil gathering stations, and select bacterial colonies through surface plate culture and agar slant purification in test tubes indoors to select microbial strains that can degrade crude oil efficiently. These microbial strains are spores Mixed species of Bacillus and Pseudomonas.

[0032] S2: Expansion of strains:

[0033] The microbial strains bred in the room are cultured in Erlenmeyer flasks, scaled up in seed tanks, and expanded in main fermentation tanks to produce microbial fermentation liquids that meet the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com