Preparation method of high-purity sodium pantothenate

A sodium pantothenate, high-purity technology, applied in the field of medicine, can solve the problems of difficulty, harsh conditions, and long crystal growth time, and achieve the effects of uniform particle size, simple operation and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

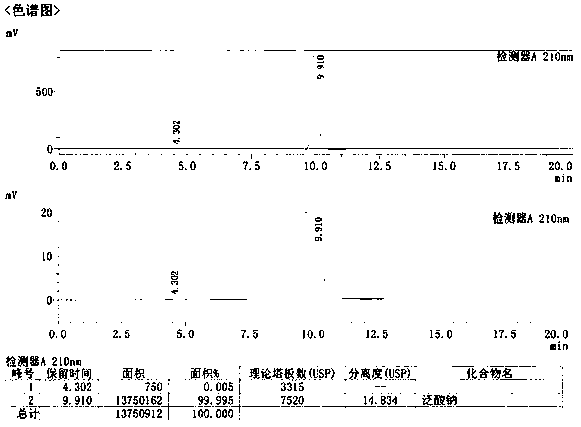

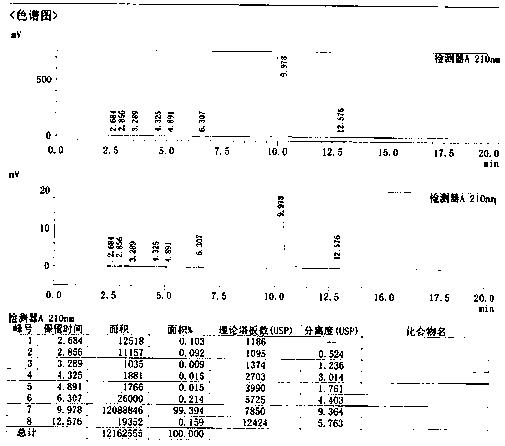

Image

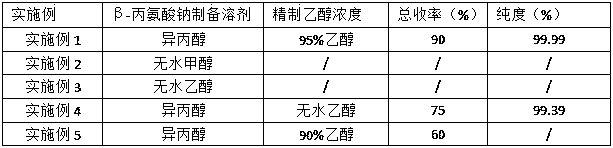

Examples

Embodiment 1

[0032] (1) Preparation of sodium β-alanine

[0033] Add 90kg of isopropanol, 20kg of β-alanine, and 9kg of sodium hydroxide into a 200L reaction tank, heat to 60±5°C, and stir for 1-3h. Stop heating, lower the temperature to 5-15°C, stir and crystallize for 3h. Put the material in the tank into the centrifuge for centrifugation, collect the filter cake to obtain sodium β-alanine (wet product), dry the wet product at a temperature of 85±5°C for 12 hours, collect the material after cooling to room temperature, take a sample and weigh it , to obtain β-alanine sodium with a yield of 95%.

[0034] (2) Preparation of sodium pantothenate (crude product)

[0035] Add isopropanol (11.2 times the weight of sodium β-alanine) to the 500L reaction tank, start stirring, add D-pantoate lactone (1.17 times the weight of sodium β-alanine), add β-propanol Sodium amino acid (full amount in the previous process), heating, temperature control 65±5°C, and reacting for 5 hours. Stop heating, coo...

Embodiment 2

[0039] (1) Preparation of sodium β-alanine

[0040] Add 90g of anhydrous methanol, 20g of β-alanine, and 9g of sodium hydroxide into a 250ml flask, heat to 62°C, stir for 3h, stop heating, cool down to 10°C, stir for 3h to crystallize, no crystals precipitate.

Embodiment 3

[0042] (1) Preparation of sodium β-alanine

[0043] Add 90g of absolute ethanol, 20g of β-alanine, and 9g of sodium hydroxide into a 250ml flask, heat to 62°C, stir for 3h, stop heating, cool down to 10°C, stir for 3h to crystallize, no crystals precipitate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com