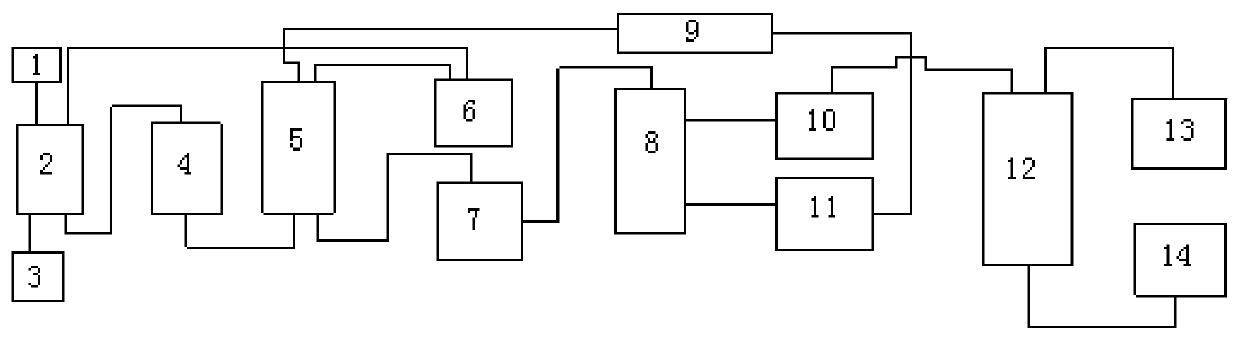

Double-circulation furfural production system and technology

A production process and production system technology, applied in the double-cycle furfural production system and process field, can solve the problems of low utilization rate of raw materials, consumption of corncobs, cellulose and lignin destruction, etc., so as to save production procedures, reduce side reactions, The effect of reducing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The above double-cycle furfural production system is used for production, and the production process includes the following steps:

[0059] 1) Add 40 g of crushed dry corn cobs (about 0.5 cm in particle diameter) into an extraction tank, add 370 g of acetic acid and sodium chloride aqueous solution, and the corn cobs will undergo hydrolysis reaction with low-concentration acetic acid to obtain xylose and The mixed solution of acetic acid, the concentration of low-concentration acetic acid is 5%, v / v, mass percentage; The temperature of hydrolysis reaction is 88 ℃, and the pressure of hydrolysis reaction is 1 atmospheric pressure, obtains the xylose that 340ml xylose content is 3.2wt% solution.

[0060] 2) Add acetic acid, sodium chloride and o-nitroanisole to the xylose solution obtained in step 1), so that the concentration of acetic acid is 5%, v / v, and the concentration of sodium chloride is 10%, mass percent The volume ratio of the addition volume of o-nitroanisole...

Embodiment 2

[0068] The above double-cycle furfural production system is used for production, and the production process includes the following steps:

[0069] 1) Add 40 g of crushed dry corn cobs to the extraction tank, add 370 g of acetic acid and sodium chloride aqueous solution, the corn cobs will undergo hydrolysis reaction with low-concentration acetic acid to obtain a mixed solution of xylose and acetic acid, low-concentration acetic acid The concentration of sodium chloride is 1%, v / v, and the concentration of sodium chloride is 5%, mass percentage; The temperature of hydrolysis reaction is 90 ℃, and the pressure of hydrolysis reaction is 1 atmospheric pressure, obtains 345ml xylose content and is 3.1wt% xylose sugar solution.

[0070] 2) Add acetic acid, sodium chloride and o-nitroanisole to the xylose solution obtained in step 1), so that the concentration of acetic acid is 6%, v / v, and the concentration of sodium chloride is 13%, mass percent The volume ratio of the addition vo...

Embodiment 3

[0078] The above double-cycle furfural production system is used for production, and the production process includes the following steps:

[0079]1) Add 40 g of crushed dry corn cobs to the extraction tank, add 370 g of acetic acid and sodium chloride aqueous solution, the corn cobs will undergo hydrolysis reaction with low-concentration acetic acid to obtain a mixed solution of xylose and acetic acid, low-concentration acetic acid The concentration of sodium chloride is 2%, v / v, and the concentration of sodium chloride is 5%, mass percent; The temperature of hydrolysis reaction is 85 ℃, and the pressure of hydrolysis reaction is 1 atmospheric pressure, obtains the xylose that 338ml xylose content is 3wt%. solution.

[0080] 2) Add acetic acid, sodium chloride and o-nitroanisole to the xylose solution obtained in step 1), so that the concentration of acetic acid is 6%, v / v, and the concentration of sodium chloride is 5%, mass percent The volume ratio of the addition volume of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com