Heat-resistant primer and preparation method thereof

A primer and heat-resistant technology, used in coatings, fire-resistant coatings, polyurea/polyurethane coatings, etc., can solve the problems of increasing construction difficulty, high hardness and poor flexibility of silicone systems, and achieve fire-resistant performance, increase Adhesive, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

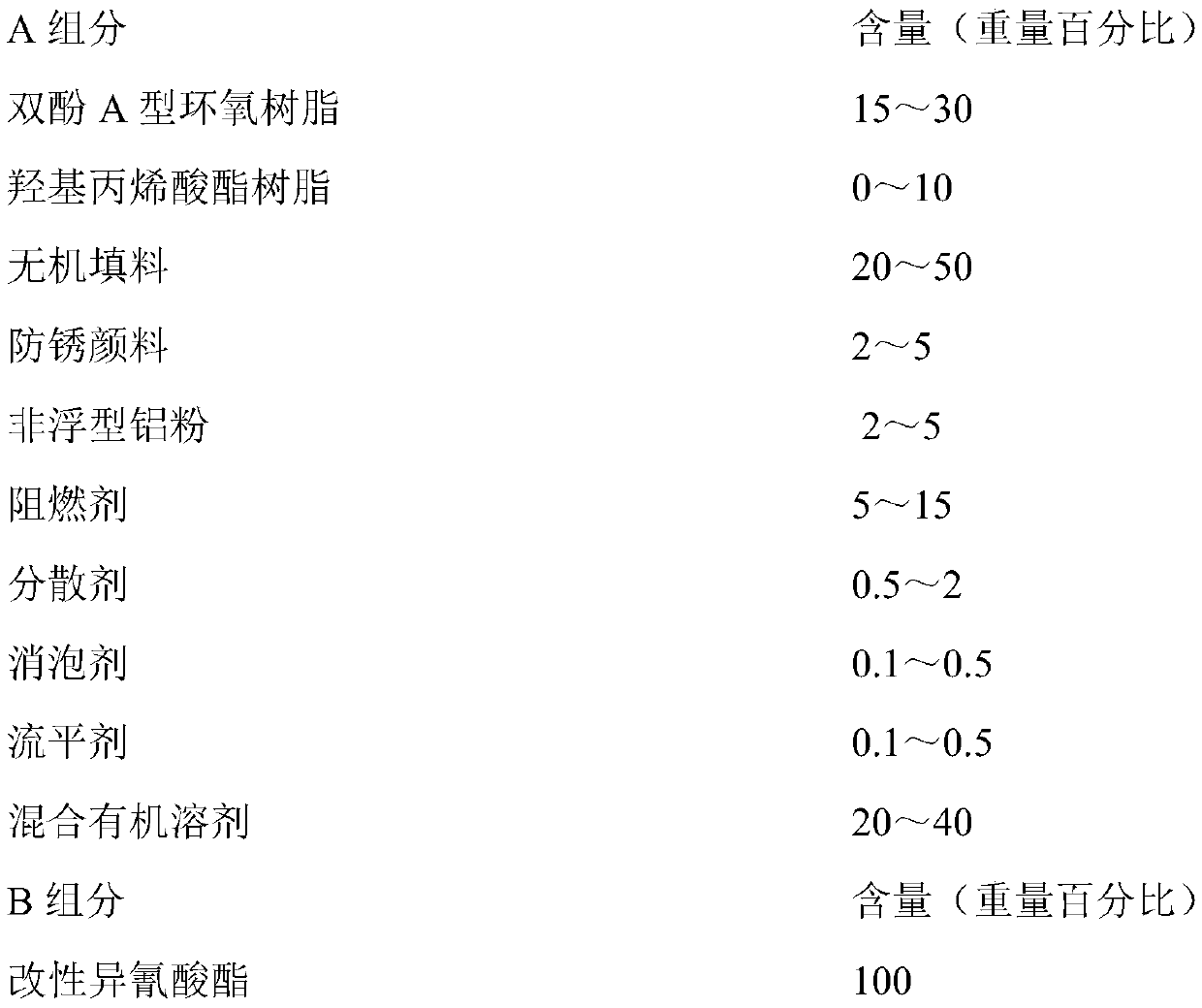

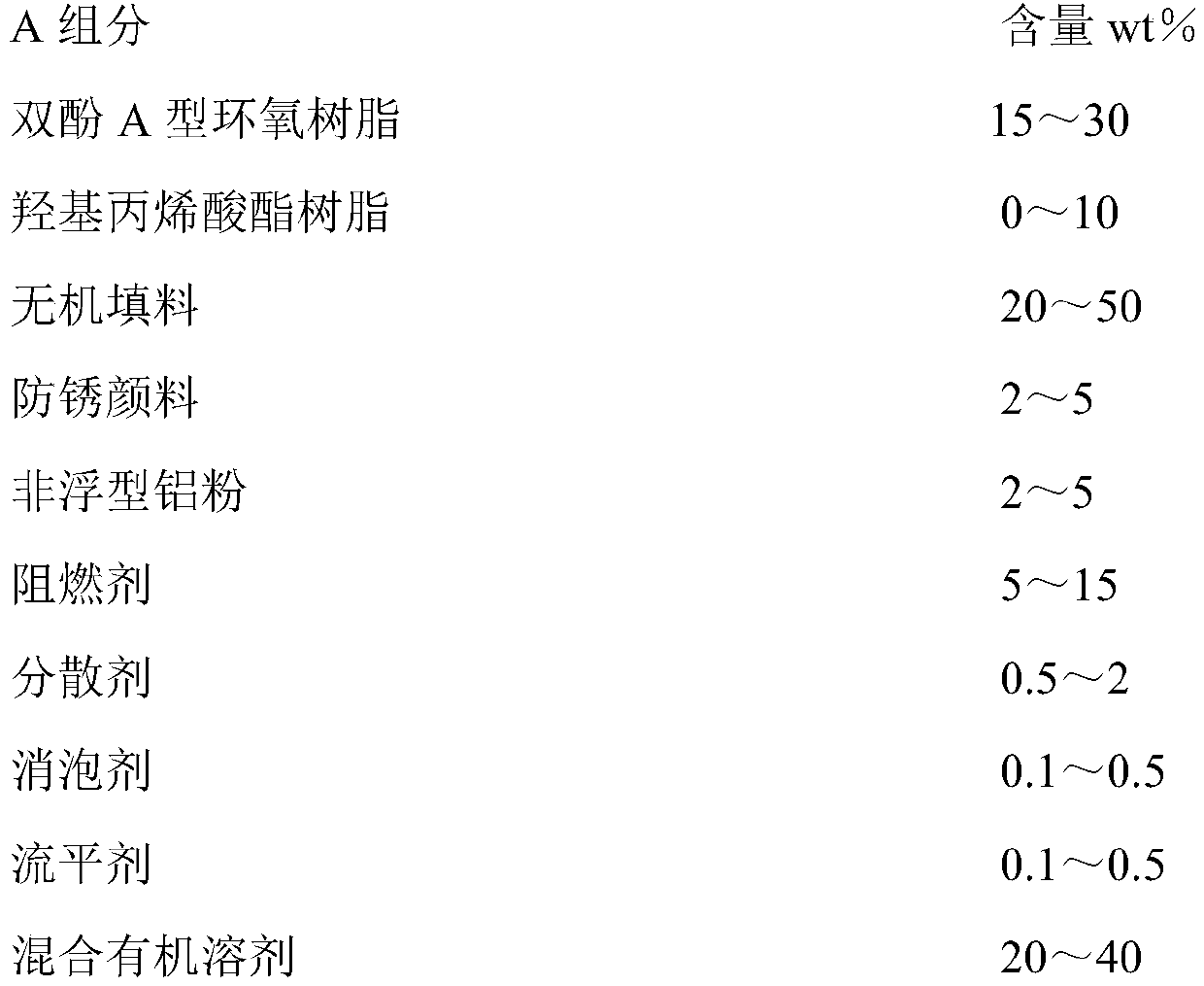

[0033]

[0034]

[0035] Concrete preparation steps:

[0036] 1. Prepare mixed organic solvent: mix xylene, butyl acetate, and propylene glycol methyl ether acetate in a weight ratio of 5:3:2;

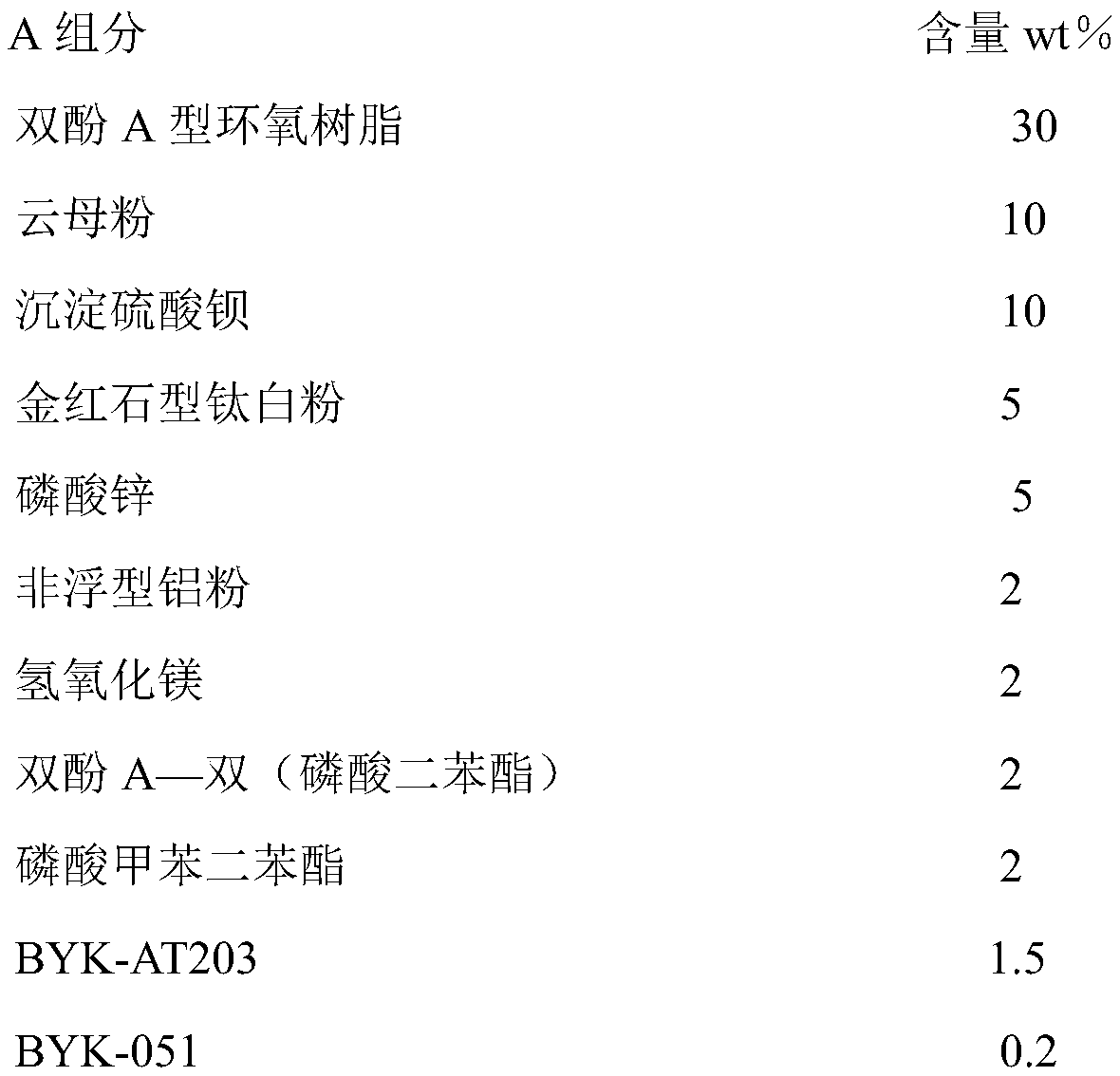

[0037]2. Preparation of component A: add 30g of bisphenol A epoxy resin (epoxy value 0.51) in component A to the mixed organic solvent under stirring at a rotation speed of 600-700r / min, and wait until the resin is completely dispersed Finally, add 10g of mica powder, 10g of precipitated barium sulfate, 5g of rutile titanium dioxide, 5g of zinc phosphate, 2g of magnesium hydroxide, 2g of bisphenol A-bis(diphenyl phosphate), 2g of toluene diphenyl phosphate (unless the floating type All ingredients except aluminum powder and additives) use a basket sand mill at a speed of 1900-2000r / min, grind to a fineness of ≤45μm, add 1.5g BYK-AT203, 0.2g BYK-051, 0.3g BYK-310, filter through 80 mesh filter, add 2g of non-leafing aluminum powder under stirring at 200-300r / min, after dispersing...

Embodiment 2

[0044]

[0045] 1. Prepare mixed organic solvent: mix xylene, butyl acetate, and propylene glycol methyl ether acetate in a weight ratio of 1:1:1;

[0046] 2. Preparation of component A: Add 15g of bisphenol A epoxy resin (epoxy value 0.44) and 5g of hydroxyacrylate resin in component A to the mixed organic solvent under stirring at a speed of 600-700r / min After the resin is completely dispersed, add 3g rutile titanium dioxide, 12g fumed silica, 5g clay, 10g talcum powder, 5g aluminum tripolyphosphate, 5g triphenyl phosphate, 2g aluminum hydroxide, 1g antimony trioxide , use a basket sand mill with a speed of 1900-2000r / min, grind to a fineness of ≤45μm, add 1.5g BYK-161, 0.1gBYK-065, 0.4gBYK-333 while stirring at a speed of 600-700r / min, Filter through an 80-mesh filter, add 5g of non-leafing aluminum powder under stirring at 200-300r / min, and disperse evenly to obtain component A;

[0047] 3.B component: add IPDI in the reaction kettle, after heating up to 50°C, N 2 Und...

Embodiment 3

[0052]

[0053]

[0054] 1. Prepare mixed organic solvent: mix xylene, butyl acetate, and propylene glycol methyl ether acetate in a weight ratio of 1:1:1;

[0055] 2. Preparation of component A: Add 20g of bisphenol A epoxy resin (epoxy value 0.21) and 10g of hydroxyacrylate resin in component A to the mixed organic solvent under stirring at a speed of 600-700r / min. After the resin is completely dispersed, add 2g rutile titanium dioxide, 6g heavy calcium, 4g clay, 8g mica powder, 2g zinc powder, 10g dimethyl methylphosphonate, 2g magnesium hydroxide, and use a basket sand mill , at a speed of 1900-2000r / min, grind to a fineness ≤45μm, add 0.5g BYK-9076, 0.1g BYK-053, 0.4g BYK-331, 80-mesh filter under stirring at a speed of 600-700r / min Filtrate, add 2g of non-leafing aluminum powder and 2g of expandable graphite under stirring at 200-300r / min, and obtain component A after dispersing evenly;

[0056] 3.B component: add IPDI in the reaction kettle, after heating up to 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com