Preparing method of TiO2/MoS2 ultra-thin nanosheet array composite

A technology of nanosheet array and composite material, which is applied in the field of preparation of TiO2/MoS2 ultrathin nanosheet array composite material, can solve the problem of few reduction reports, achieve green synthesis route, good practical value and development prospect, and method repeatability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

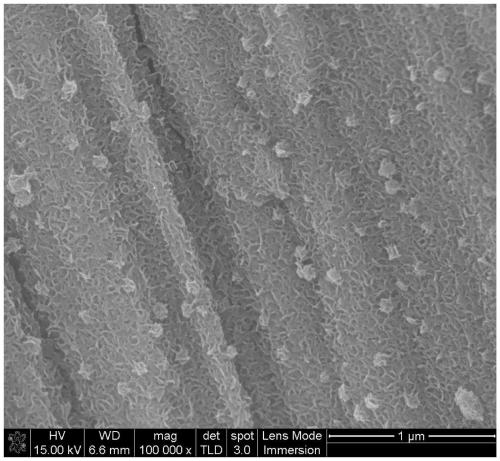

[0029] A kind of TiO 2 / MoS 2 A method for preparing an ultrathin nanosheet array composite material, comprising the following steps:

[0030] S1. Sonicate a 1*4cm molybdenum mesh in acetone solution, ethanol solution, hydrochloric acid solution and high-purity water for 1 hour respectively, take out the molybdenum mesh, and dry it in a vacuum drying oven;

[0031] S2. Weigh 10 mg of ammonium tetrathiomolybdate, add it to the reaction kettle, measure 30 mL of N,N-dimethylformamide with a graduated cylinder, pour it into the reaction kettle, and pipette 50 uL of hydrazine monohydrate, Add to the reaction kettle and stir for 15min;

[0032] S3. Put the molybdenum mesh treated in step S1 into the reaction kettle with tweezers, tighten the reaction kettle, put it into an oven, and conduct a hydrothermal reaction at 200° C. for 15 hours;

[0033] S4. After cooling to room temperature, use clean tweezers to take out the molybdenum mesh after step S3, ultrasonically wash it with d...

Embodiment 2

[0044] This example aims at TiO 2 / MoS 2 Ultrathin nanosheet array composites and MoS 2 Experimental comparison of the difference in electrocatalytic activity, in order to further understand the TiO prepared by the method of Example 1 2 / MoS 2 Properties of ultrathin nanosheet array composites.

[0045] TiO 2 / MoS 2 Ultrathin nanosheet array composites and MoS 2 The electrocatalytic LSV curve of Figure 9 shown.

[0046] TiO 2 / MoS 2 Ultrathin nanosheet array composites and MoS 2 Each piece is properly cut as the working electrode, the reference electrode is Ag / AgCl electrode, and the counter electrode is platinum electrode. The electrode is scanned by linear cyclic voltammetry, the scanning range is -0.61V--1.81V, and the scanning speed is 50mV / s . Through the above experimental method, get in 0.5M KHCO 3 The LSV curve in the electrolyte is as Figure 9 shown. The figure shows that loaded TiO 2 After TiO 2 / MoS 2 The hydrogen evolution activity of ultrathin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com