A kind of emulsification process of repairing cream

A shea butter, heating and stirring technology, applied in skin care preparations, cosmetics, cosmetic preparations, etc., can solve emulsification effects such as difficult to control appearance, consistency, liposome stability and storage stability, etc. Unfavorable cream application and other problems, to achieve the effect of improving dispersion and bioavailability, uniform appearance, and improving physical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

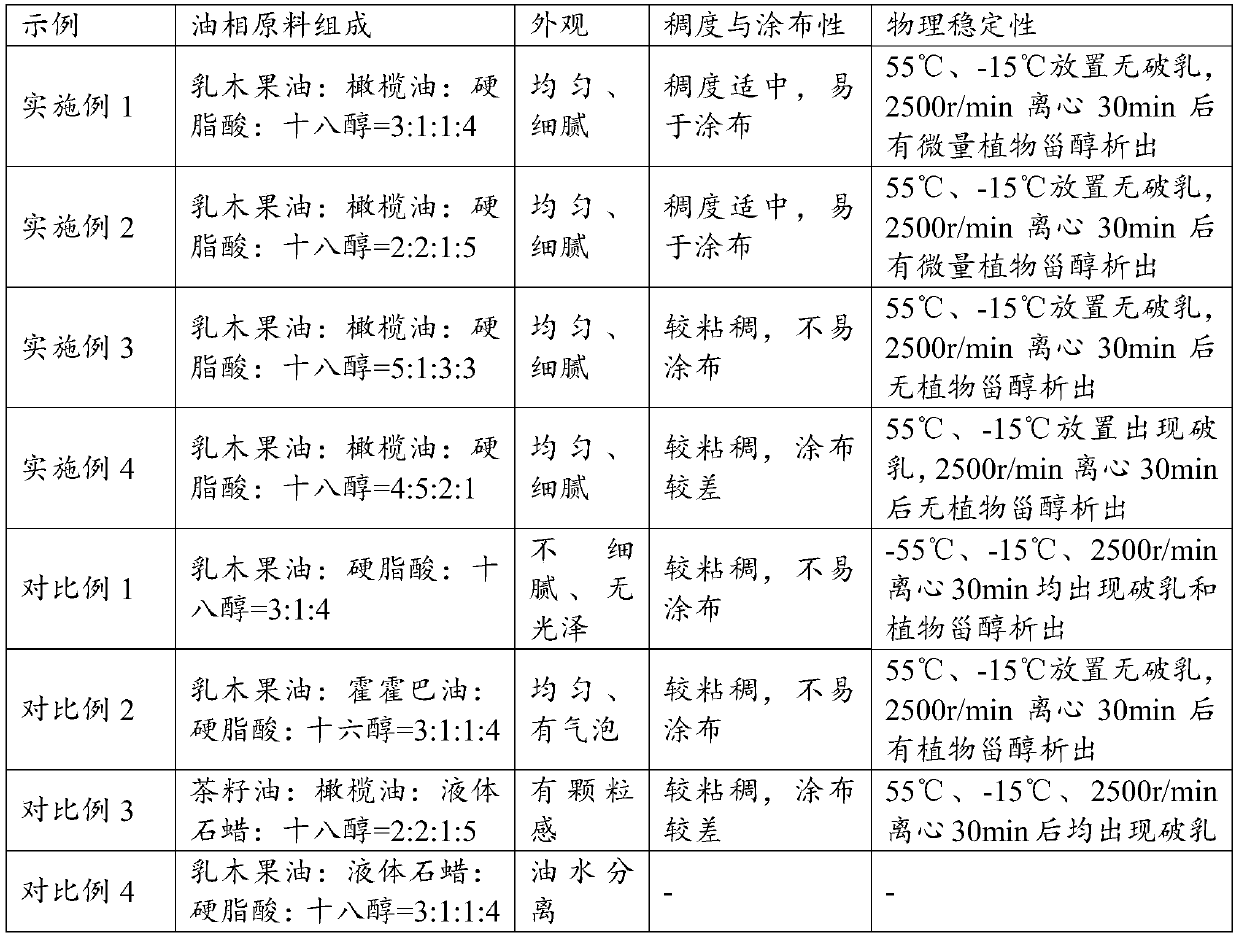

[0041] Examples 1-4 all adopt the above-mentioned preparation process to obtain a kind of repairing cream. The difference is that the composition of the oil phase raw materials used in each example is different, and the rest of the components and conditions are the same. Among them, the emulsification component uses 1.2% hydrogenated egg Phospholipids. The selection of specific raw materials and the evaluation results are shown in Table 1.

[0042] Table 1 The influence of the composition of oil phase raw materials on the emulsification process of repair cream

[0043]

[0044] It can be seen from Table 1 that the composition of different oil phase raw materials has a great influence on the emulsification process of repair cream. Compared with other oil phase raw materials used in the comparative example, the repair cream obtained by mixing the oil phase raw materials shea butter, olive oil, stearic acid and stearyl alcohol selected in the embodiment is more uniform and de...

Embodiment 5-10

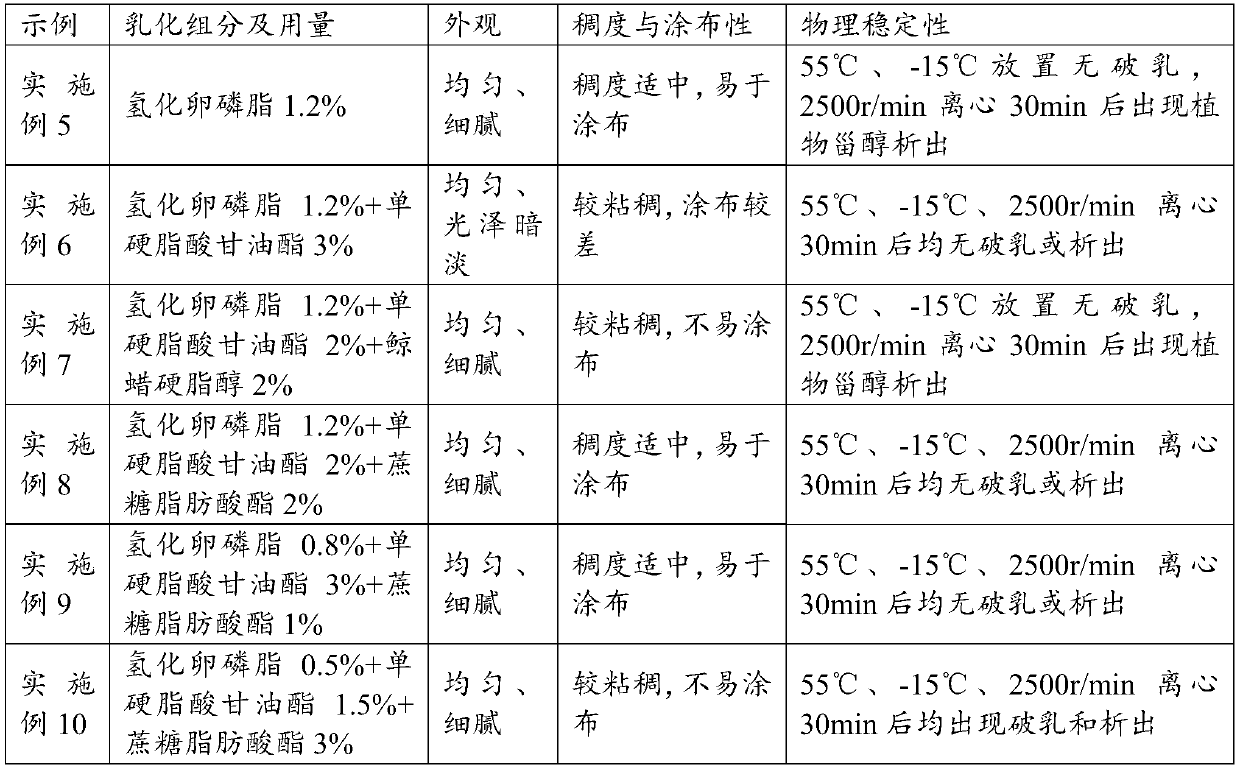

[0046] The physical stability of the repairing cream in the above examples is relatively poor, and phytosterols are prone to precipitation after centrifugation. Therefore, the oil phase raw materials in Example 1 are used as the preferred solution below, and its emulsified components are improved to prepare Example 5. -10 to improve its physical stability. The selection and results of specific emulsifying components are shown in Table 2.

[0047] Table 2 The influence of emulsifying components on the emulsification process of repair cream

[0048]

[0049] It can be seen from Table 2 that the selection of emulsifying components has a great influence on the emulsification process of repair cream, especially the physical stability of repair cream. Compared with Example 5 using a single emulsifying component, Examples 6-9 using two or more emulsifying components showed good physical stability, placed at 55°C or -15°C or centrifuged at 2500r / min No demulsification or phytoste...

Embodiment 11-16

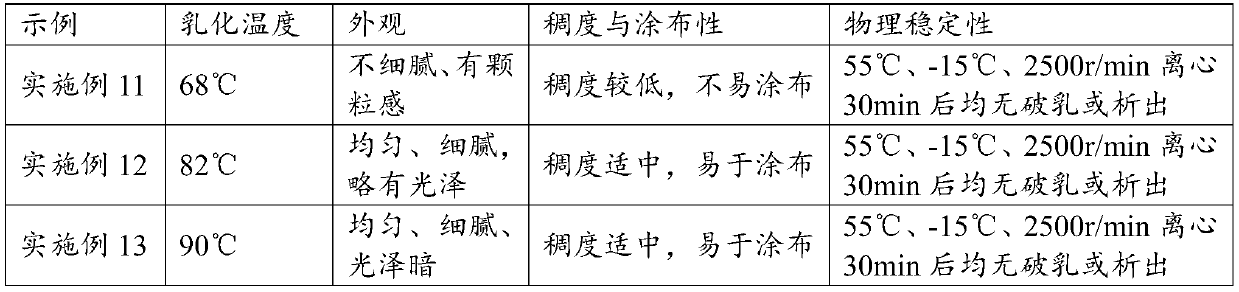

[0052] The emulsification conditions for constant temperature emulsification of the oil phase and the water phase in the emulsification process are further optimized for the repair cream containing the above components and ratios. The results are shown in Table 3 and Table 4.

[0053] Table 3 Effect of emulsification temperature on emulsification process of repair cream

[0054]

[0055] The impact of table 4 emulsification time on the emulsification process of repair cream

[0056]

[0057] As can be seen from Table 3 and Table 4, before adding phytosterol liposomes, the emulsification temperature and emulsification time of the emulsification after mixing the oil phase and the water phase have a certain influence on the appearance, consistency and applicability of the finally obtained repair cream . Moreover, when the emulsification temperature is 82°C and the emulsification time is 20 minutes, the emulsification effect of the repair cream obtained is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com