A tile luster repairing agent and preparation method thereof

A repairing agent and gloss technology, which is applied in the direction of chemical instruments and methods, polishing compositions, detergent compositions, etc., can solve problems such as dull and black tile surfaces, tile surface tarnish, tile surface burns and corrosion, etc., to improve gloss , prevent dirt from penetrating into tiles and wear tiles, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A ceramic tile gloss restoration agent, said tile gloss restoration agent is composed of A component and B component in a volume ratio of 3:2, and said A component includes the following raw materials in parts by weight:

[0044]

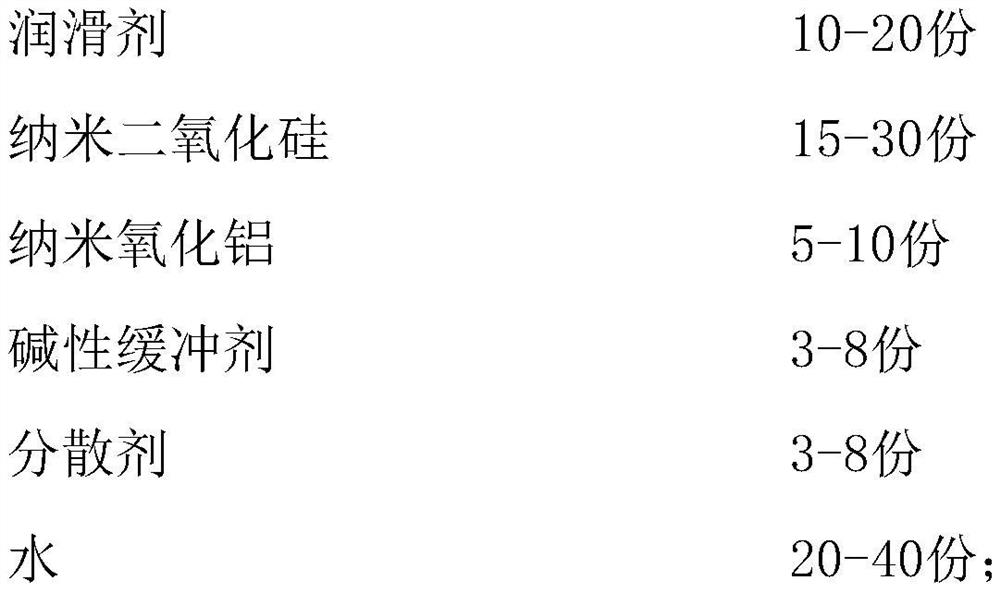

[0045] The B component includes the following raw materials in parts by weight:

[0046]

[0047] The alkaline buffer is an ammonia-ammonium chloride buffer solution with a pH value of 8.5-9.5.

[0048] The dispersant is prepared by mixing sodium polyacrylate and acrylic acid-maleic anhydride copolymer at a weight ratio of 2.5:1.

[0049] The lubricant is prepared by mixing pentaerythritol stearate, polyethylene wax, ethylene bisstearamide, turpentine and stearate in a weight ratio of 2:1:4:1:4.

[0050] The brightener is prepared by mixing sulfonated melamine-formaldehyde resin and a non-ionic surfactant in a weight ratio of 6:1.5; the non-ionic surfactant is polyethylene glycol.

[0051] The crystallization agent is formed by mixing...

Embodiment 2

[0063] A tile gloss repairing agent, said tile gloss repairing agent is composed of A component and B component in a volume ratio of 2:1, and said A component includes the following raw materials in parts by weight:

[0064]

[0065]

[0066] The B component includes the following raw materials in parts by weight:

[0067]

[0068] The alkaline buffer is a sodium carbonate-sodium bicarbonate buffer solution with a pH value of 8.5-9.5.

[0069] The dispersant is prepared by mixing sodium polyacrylate and acrylic acid-maleic anhydride copolymer at a weight ratio of 2:1.

[0070] The lubricant is prepared by mixing pentaerythritol stearate, polyethylene wax, ethylene bisstearamide, turpentine and stearate in a weight ratio of 2:1:2:0.5:3.

[0071] The brightener is prepared by mixing sulfonated melamine formaldehyde resin and non-ionic surfactant in a weight ratio of 5:1; the non-ionic surfactant is nonylphenol polyoxyethylene ether.

[0072] The crystallization agent ...

Embodiment 3

[0084] A tile gloss repairing agent, said tile gloss repairing agent is composed of A component and B component in a volume ratio of 4:3, and said A component includes the following raw materials in parts by weight:

[0085]

[0086] The B component includes the following raw materials in parts by weight:

[0087]

[0088] The alkaline buffer is an ammonia-ammonium chloride buffer solution with a pH value of 8.5-9.5.

[0089] The dispersant is prepared by mixing sodium polyacrylate and acrylic acid-maleic anhydride copolymer in a weight ratio of 3:1.

[0090] The lubricant is prepared by mixing pentaerythritol stearate, polyethylene wax, ethylene bisstearamide, turpentine and stearate in a weight ratio of 2:1:6:1.5:5.

[0091] The brightener is prepared by mixing sulfonated melamine-formaldehyde resin and a non-ionic surfactant in a weight ratio of 8:2; the non-ionic surfactant is polyethylene glycol.

[0092] The crystallization agent is formed by mixing glass resin a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com