Conductive polymer binder and preparation method and applications thereof

A technology of conductive polymers and binders, which is applied in circuits, electrical components, battery electrodes, etc., can solve the problems of no conductivity and low bonding strength, and achieve improved cycle stability, good affinity, and improved Effect of rate and low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

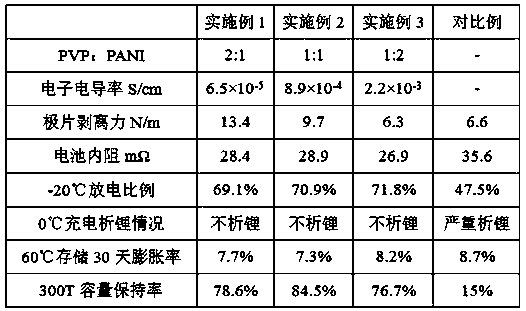

Examples

specific Embodiment approach 1

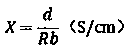

[0016] Specific embodiment one: what this embodiment records is a kind of conductive polymer binder, and described binder is polyvinylpyrrolidone and polyaniline reaction copolymer PVP-PANI, and its chemical structural formula is as follows:

[0017] .

specific Embodiment approach 2

[0018] Specific embodiment two: a kind of conductive polymer adhesive described in specific embodiment one, in described adhesive, the mass proportion of polyaniline in PVP-PANi adhesive is 10%~90%, The preferred ratio is 30%~70%; by controlling the mass ratio of polyaniline below 90%, the water solubility and bonding strength of the binder can be guaranteed, and if it is controlled above 10%, it can ensure that the binder has good electronic conductivity. Generality. The molecular weight of PVP is 1,000-3,000,000, preferably 10,000-100,000. By controlling the molecular weight of PVP within the above range, it can ensure that the prepared adhesive has good bonding strength.

specific Embodiment approach 3

[0019] Embodiment 3: An application of the conductive polymer binder described in Embodiment 1 or Embodiment 2. The conductive polymer binder is used in silicon-based negative electrodes of lithium-ion batteries.

[0020] Specific embodiment three: a preparation method of the conductive polymer binder described in specific embodiment one or two, the method is specifically: dissolving PVP in the reaction medium, adding the distilled aniline monomer, and continuing to stir , Initiate polymerization under the action of an initiator to generate dark green solution, filter and wash to obtain PVP-PANI dark green powder.

[0021] Embodiment 5: In the method for preparing a conductive polymer binder described in Embodiment 4, the reaction medium is at least one of hydrochloric acid and anhydrous acetic acid, preferably anhydrous acetic acid.

[0022] Specific embodiment six: the preparation method of a kind of conductive polymer binder described in specific embodiment four, described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com