Environment-friendly flame-retarding and smoke-inhibiting agent and preparation method thereof

A smoke suppressant, environment-friendly technology, applied in the field of magnesium hydroxide flame retardant smoke suppressant and its preparation, can solve the problems of reduced maximum smoke density, unfavorable industrial production, complex preparation process, etc., to improve dispersibility, increase resistance Combustion and smoke suppression effect, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

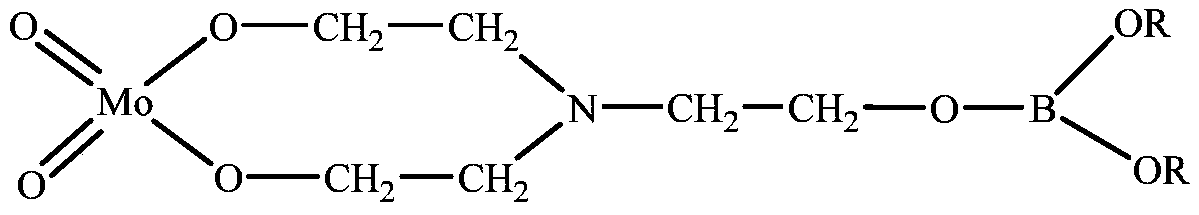

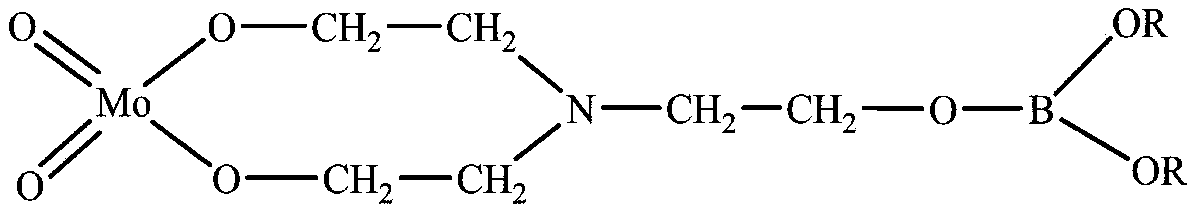

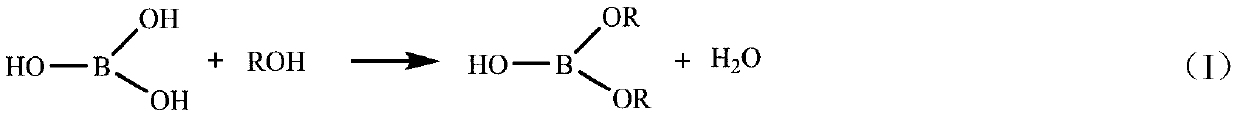

Method used

Image

Examples

Embodiment 1

[0033] Weigh 1000g of magnesium hydroxide (median diameter 30μm) into a 5L high-speed mixer at 60°C, stir for 10min at a stirring speed of 100r / min; add 5gMBR 1, and continue to stir for 30 min at a stirring speed of 1000 r / min; keep the uniformly mixed powder in a blast drying oven at 120°C for 3 h, seal it and put it in a drying dish for later use.

Embodiment 2

[0035] Weigh 1000g of aluminum hydroxide (median diameter 10μm) into a 5L high-speed mixer at 80°C, stir for 5min at a stirring speed of 300r / min; add 15g of MBR 3 , continue to stir for 15 min at a stirring speed of 1200 r / min; keep the uniformly mixed powder in a blast drying oven at 100°C for 1 h, seal it and put it in a drying dish for later use.

Embodiment 3

[0037] Weigh 1000g of hydrotalcite (median diameter 1μm) and add it to a 5L high-speed mixer at 80°C, and stir for 10min at a stirring speed of 500r / min; add 25g of MBR 5 , and continue to stir for 30 min at a stirring speed of 1500 r / min; keep the uniformly mixed powder in a blast drying oven at 120 ° C for 3 h, seal it and put it in a drying dish for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com