Ion liquid assisted magnesium lithium alloy anodic oxidation film forming method

A technology of anodic oxidation and magnesium-lithium alloy, applied in the direction of anodic oxidation, etc., to achieve good corrosion resistance, improved growth behavior, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An ionic liquid-assisted magnesium-lithium alloy anodic oxidation film-forming method may comprise: the sodium hydroxide of 50g / L, the sodium silicate of 40g / L, the sodium tetraborate of 30g / L, the dihydrate citric acid of 40g / L Sodium is mixed together to make a sodium silicate electrolyte system; then add 1-butyl-3 methylimidazolium tetrafluoroborate to make silicon The volume concentration of 1-butyl-3 methylimidazolium tetrafluoroborate in the sodium chloride electrolyte system is 4%, and the mixture is evenly mixed to obtain the magnesium-lithium alloy anode oxidation electrolyte. The magnesium-lithium alloy workpiece is used as the anode, and the stainless steel or lead plate is used as the cathode, and the constant current mode is used for anodic oxidation, and the current density of the constant current mode is 1A / dm 2 , the distance between the anode and the cathode is controlled at 10cm, the anodic oxidation time is 30min, and the temperature is 15°C. After th...

Embodiment 2

[0035] An ionic liquid-assisted magnesium-lithium alloy anodic oxidation film-forming method may comprise: the sodium hydroxide of 50g / L, the sodium silicate of 40g / L, the sodium tetraborate of 30g / L, the dihydrate citric acid of 40g / L Sodium is mixed together to make a sodium silicate electrolyte system; then add 1-butyl-3 methylimidazolium tetrafluoroborate to make silicon The volume concentration of 1-butyl-3 methylimidazolium tetrafluoroborate in the sodium chloride electrolyte system is 2%, and the mixture is evenly mixed to obtain the magnesium-lithium alloy anode oxidation electrolyte. The magnesium-lithium alloy workpiece is used as the anode, and the stainless steel or lead plate is used as the cathode, and the constant voltage mode is used for anodizing. The voltage of the constant voltage mode is 125V, the distance between the anode and the cathode is controlled at 10cm, the anodizing time is 30min, and the temperature is 15℃ , after the anodic oxidation is finished...

Embodiment 3

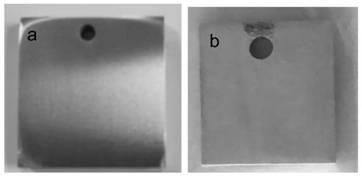

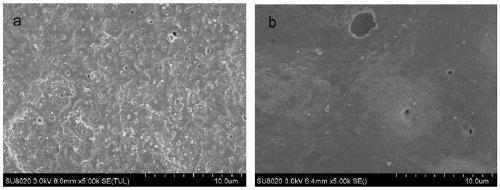

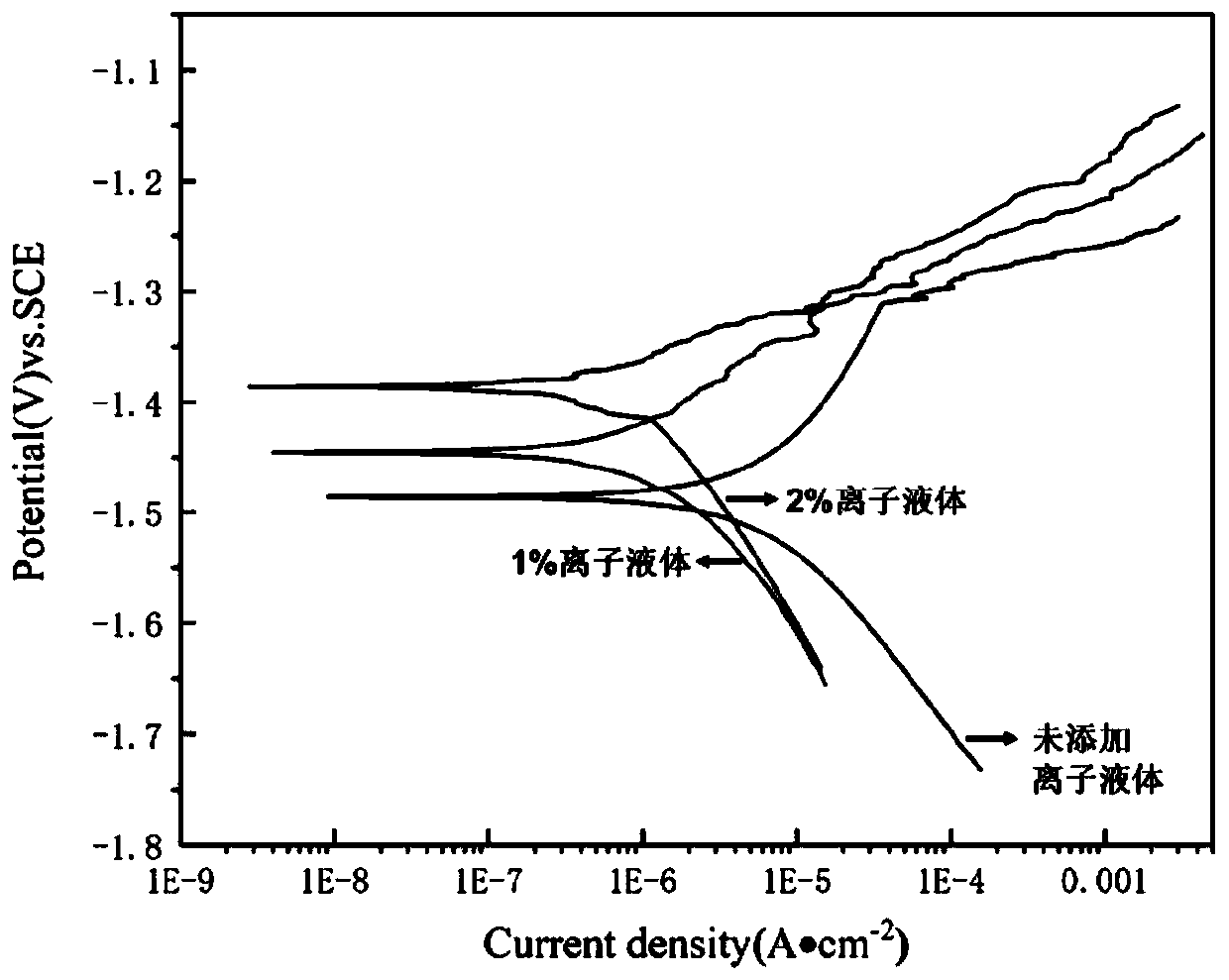

[0038] An ionic liquid-assisted magnesium-lithium alloy anodic oxidation film-forming method may comprise: the sodium hydroxide of 50g / L, the sodium silicate of 40g / L, the sodium tetraborate of 30g / L, the dihydrate citric acid of 40g / L The sodium is mixed together to obtain a sodium silicate electrolyte system; the sodium silicate electrolyte system is divided into three parts, and then 1-butyl-3 methylimidazolium tetrafluoroborate is added to make the addition of 1-butyl- The volume concentration of 1-butyl-3 methylimidazolium tetrafluoroborate in the sodium silicate electrolyte system after 3-methylimidazolium tetrafluoroborate is 0, 1%, and 2%, respectively, thereby obtaining three kinds of magnesium Lithium alloy anodizing electrolyte. The three kinds of magnesium-lithium alloy anodic oxidation electrolytes are used for anodic oxidation, the magnesium-lithium alloy workpiece is used as the anode, and the stainless steel or lead plate is used as the cathode, and the constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com