Solar cell module used in building field and preparation method thereof

A technology of solar cell components and solar cells, applied in electrical components, sustainable buildings, circuits, etc., can solve problems affecting power generation efficiency, exposure of the background color of the electrode layer, and restricted use of the environment, etc. The effect of high conversion efficiency and wide range of substrate sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

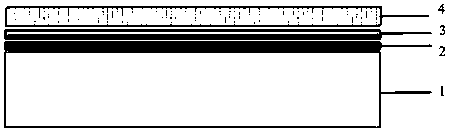

[0067] A solar cell, the base of which is a flexible stainless steel foil with a thickness of 0.2 mm, on which a power generation electrode layer is arranged, and a wire lead-out electrode is arranged. A protective layer is arranged on the battery layer, and the material of the protective layer is water-based glaze, which includes soluble silicon inorganic metal salt, has a thickness of 0.1mm, and has a marble pattern.

[0068] Its preparation method is as follows:

[0069] Clean the flexible stainless steel foil substrate and put it into the magnetron sputtering machine. In order to prevent elements in the stainless steel from diffusing into the solar cell, a 0.5 μm WTi barrier layer was first sputtered. The working gas is Ar gas, the sputtering pressure is 0.7Pa, and the background vacuum is 2.0×10 -3 Pa, the substrate is not heated during sputtering. The Mo film was prepared by the three-layer process, the sputtering pressure of the first layer was 1.5Pa, the sputtering ...

Embodiment 2

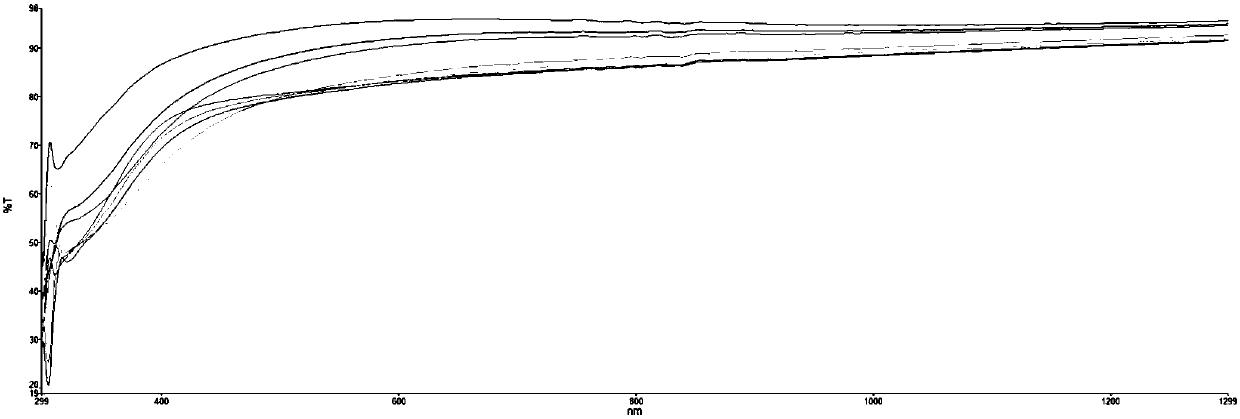

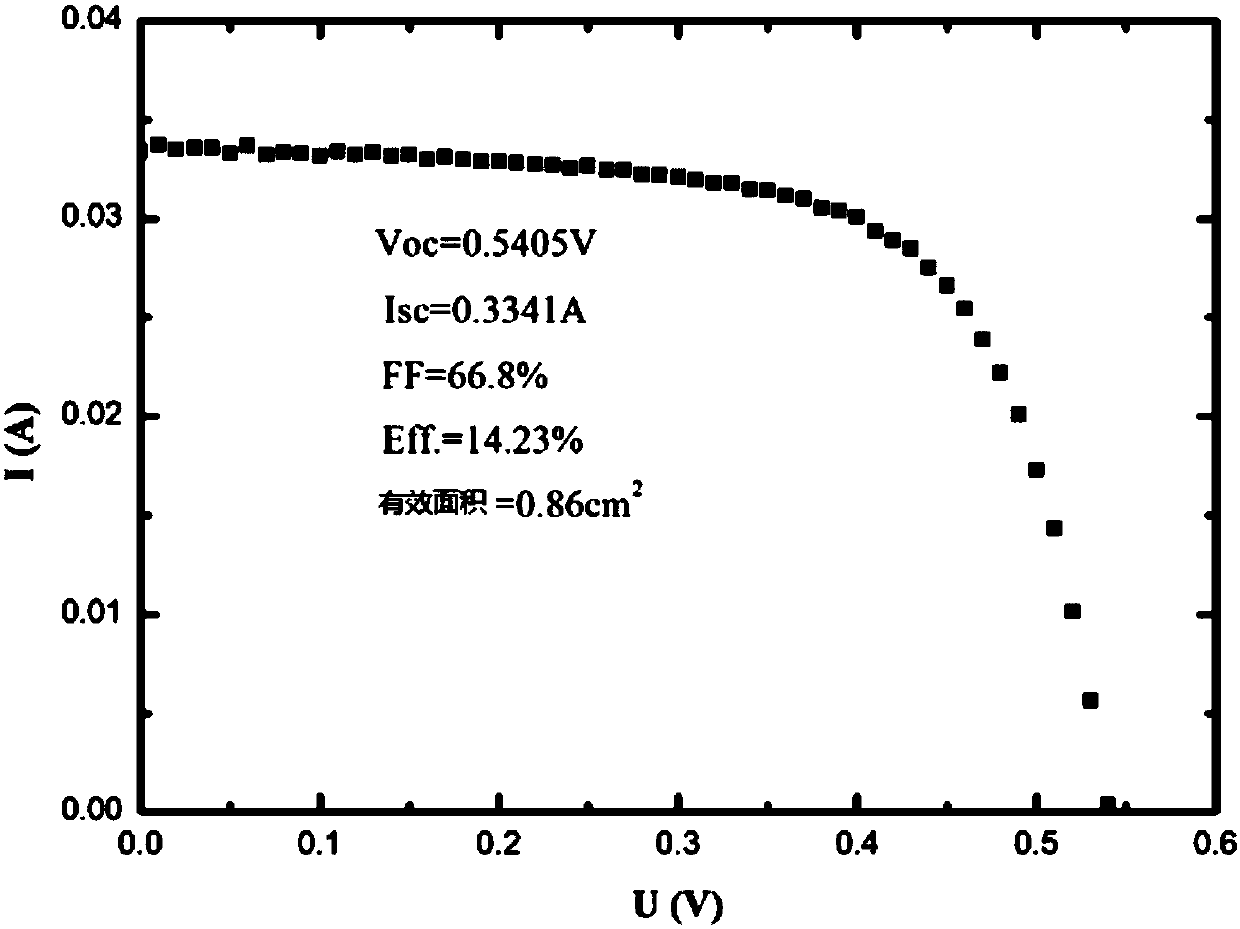

[0073]A solar cell, the substrate of which is glass with a thickness of 2.0 mm, a battery layer is arranged on it, and lead-out electrodes are arranged. The preparation process of the battery is similar to that of Example 1, the difference is that the CIGS film is replaced by Cu 2 (ZnSn)(SSe) 4 , the post-treatment process of the film is replaced by selenization or sulfuration. An encapsulation layer and a protective layer are arranged on the battery layer, and the material of the protective layer is water-based glaze, which includes soluble silicon inorganic metal salt, has a thickness of 0.1mm, and has dark brown coloring.

[0074] The solar cell can be prepared by a method similar to that of Example 1. Its transmittance for 450-760nm light is 71%, and its photovoltaic conversion efficiency is 14.1%.

[0075] The protective layer of the solar cell of the present application can also be obtained in other ways, such as coating the glaze solution on the surface of the cell l...

Embodiment 3

[0077] A solar cell, the base of which is a ceramic tile with a thickness of 2.0mm, a battery layer is arranged on it, and a wire lead-out electrode is arranged. The battery layer has a CdTe solar cell structure, and the specific preparation process is as follows: firstly, the cleaned glass substrate is placed in a sputtering apparatus, the working gas is Ar gas, the sputtering pressure is 0.7Pa, and the background vacuum is 1.5×10 -3 Pa, sputtering deposited a layer of sputtered transparent conductive oxide indium tin oxide film on glass. Subsequently, the CdS slurry was coated into a film by screen printing, dried at 90-120°C for 1-3 hours, and then dried in N 2 Sintering under atmosphere for 0.5-2 hours, the sintering temperature is 650-710°C. Then the slurry containing CdTe powder was printed onto CdS and sintered for 1 hour. Finally, carbon electrodes and Ag paste were printed on CdTe as extraction electrodes. A protective layer is arranged on the battery layer, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com