Preparation method for waterborne polyurethane binder and lithium-ion battery anode slurry containing waterborne polyurethane binder

A water-based polyurethane, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfriendly environment, cumbersome process, etc., and achieve the effect of excellent bonding performance, simple operation process and good cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

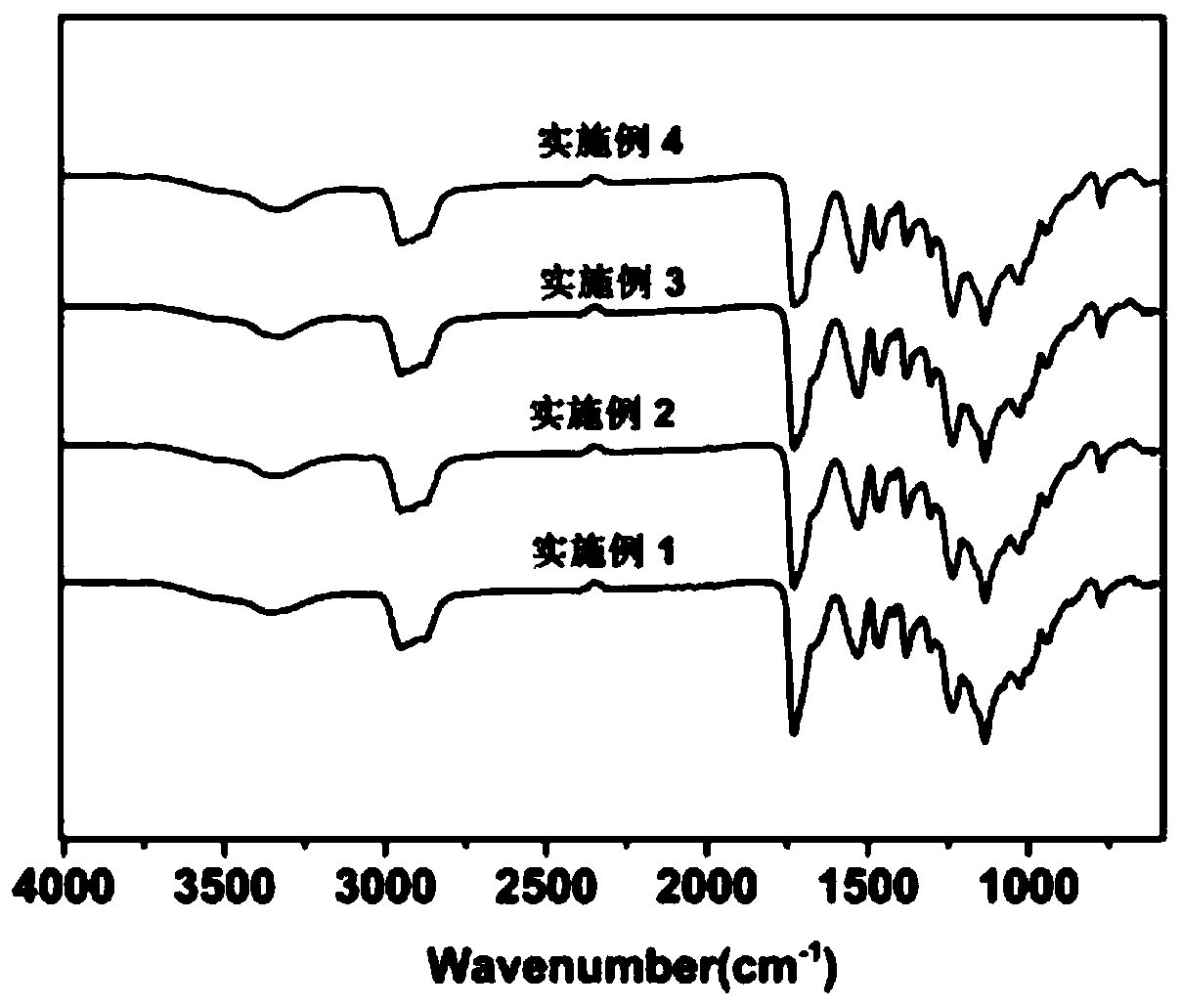

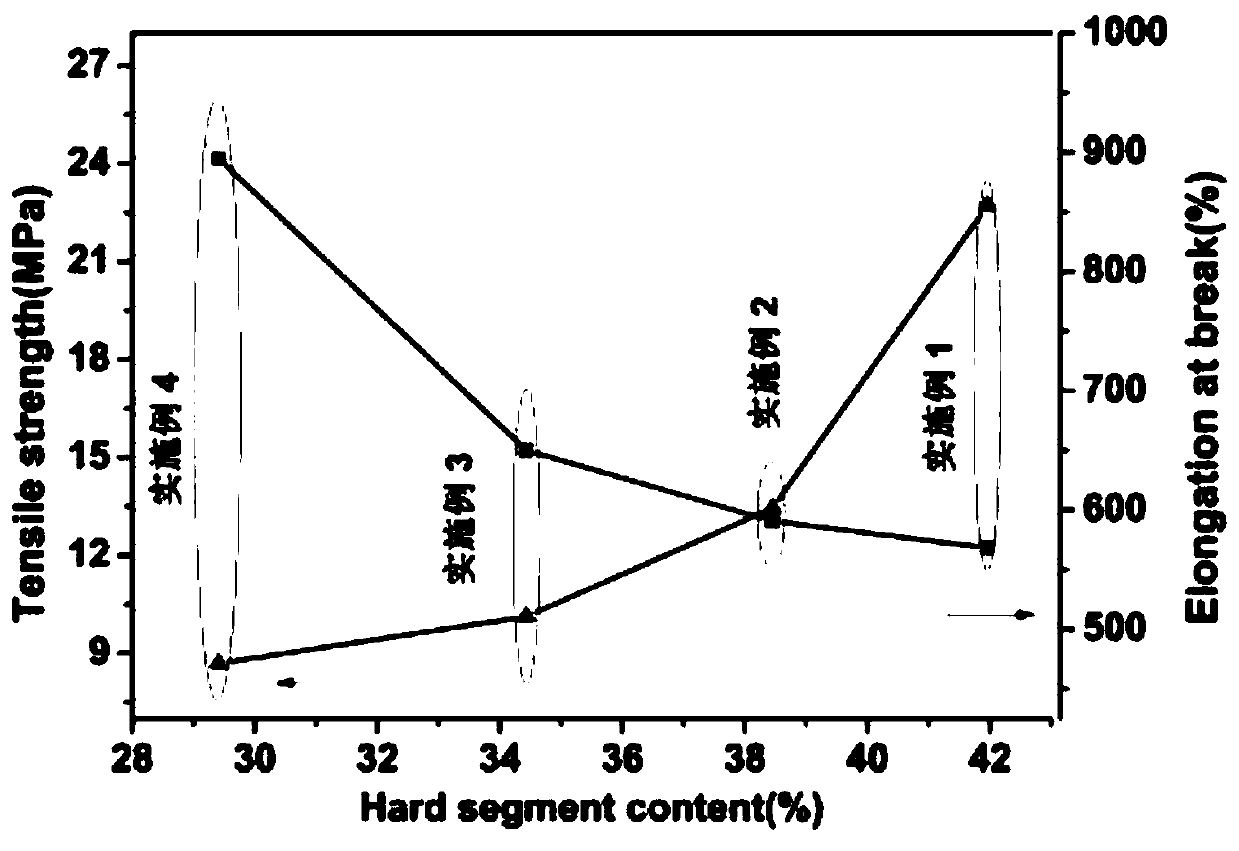

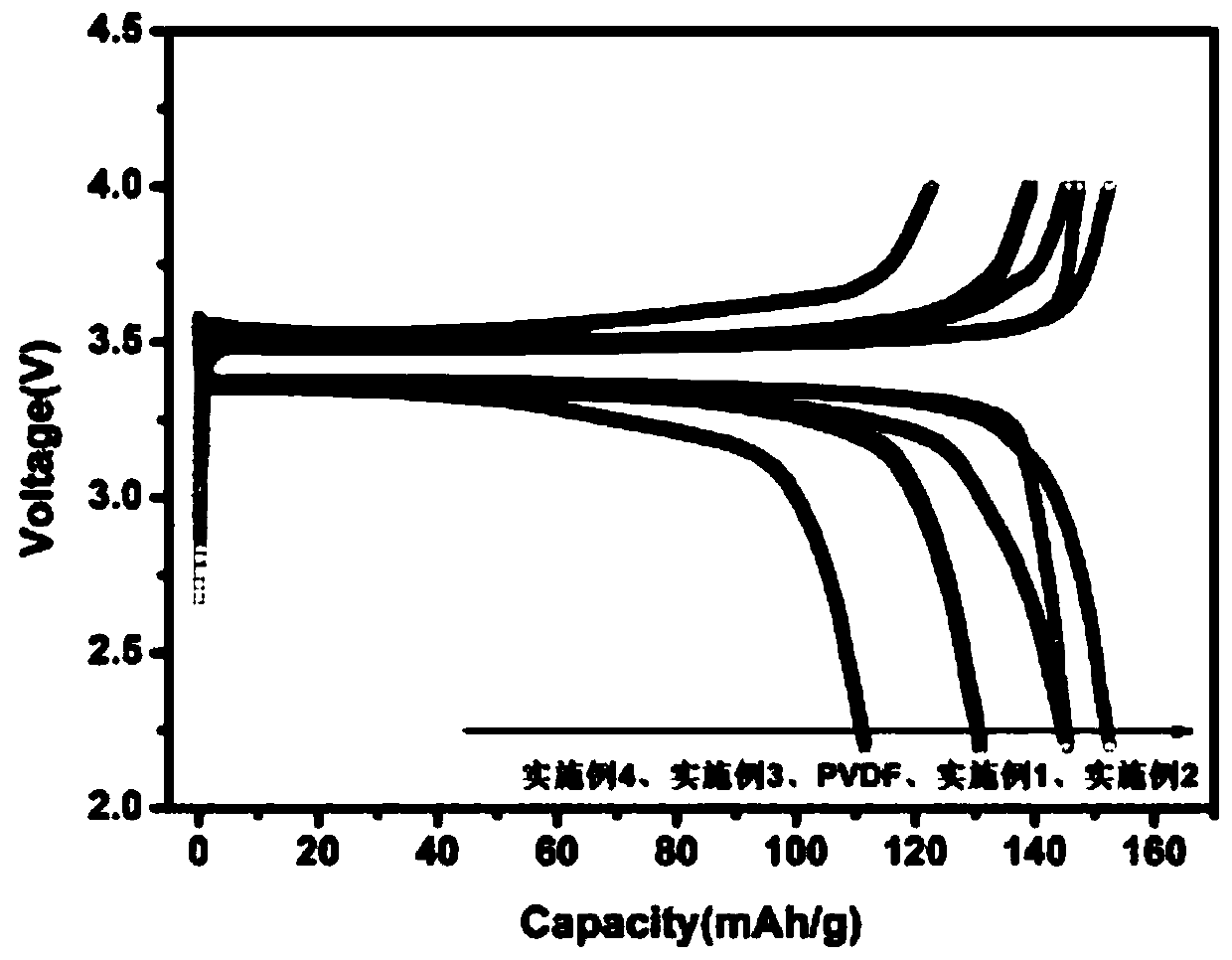

[0033] Add 17.76g isophorone diisocyanate and 40g polyneopentyl adipate diol for later use after vacuum dehydration at 110 ℃ in the four-necked flask that polytetrafluoroethylene stirring rod, spherical condenser and thermometer are housed, After stirring evenly, slowly raise the temperature to (90±2)°C, and react at constant temperature for 2 hours; cool to 50°C with ice water, add 10.6g of trimethylolpropane-polyethylene glycol monomethyl ether, stir evenly, and slowly raise the temperature to (90±2) )°C, react for 1.5h; cool down to 40°C, add 2.4g 1,4-butanediol and 15g acetone and stir evenly, then add a metered amount of catalyst, slowly raise the temperature to (70±2)°C and continue the reaction for 4h; use di-n-butyl The amine-hydrochloric acid titration method determines that the residual -NCO content reaches the theoretical value, which is the end of the reaction, and the temperature is lowered to 40°C to discharge. Under high-speed shearing, 133 g of deionized water ...

Embodiment 2

[0037] Add 22.2g isophorone diisocyanate and 40g polyneopentyl adipate diol for later use after vacuum dehydration at 110 ℃ in the four-necked flask that polytetrafluoroethylene stirring rod, spherical condenser and thermometer are housed, After stirring evenly, slowly raise the temperature to (90±2)°C, and react at a constant temperature for 2 hours; cool to 50°C with ice water, add 11.6g of trimethylolpropane-polyethylene glycol monomethyl ether, stir evenly, and slowly raise the temperature to (90±2) )°C, react for 1.5h; cool down to 40°C, add 3.6g of 1,4-butanediol and 15g of acetone and stir evenly, then add the metered catalyst, slowly raise the temperature to (70±2)°C and continue the reaction for 4h; The amine-hydrochloric acid titration method determines that the residual -NCO content reaches the theoretical value, which is the end of the reaction, and the temperature is lowered to 40°C to discharge. Under high-speed shearing, 146 g of deionized water was added for em...

Embodiment 3

[0041] Add 26.6g isophorone diisocyanate and 40g polyneopentyl glycol adipate diol for later use after vacuum dehydration at 110 ℃ in the four-necked flask that polytetrafluoroethylene stirring rod, spherical condenser and thermometer are housed, After stirring evenly, slowly raise the temperature to (90±2)°C, and react at constant temperature for 2 hours; cool to 50°C with ice water, add 12.6g of trimethylolpropane-polyethylene glycol monomethyl ether, stir evenly, and slowly raise the temperature to (90±2) )°C, react for 1.5h; cool down to 40°C, add 4.7g of 1,4-butanediol and 15g of acetone and stir evenly, then add the metered catalyst, slowly raise the temperature to (70±2)°C and continue the reaction for 4h; The amine-hydrochloric acid titration method determines that the residual -NCO content reaches the theoretical value, which is the end of the reaction, and the temperature is lowered to 40°C to discharge. Under high-speed shearing, 159 g of deionized water was added f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com