Method for maintaining continuous hydrogen production after chlorella cell death

A technology of cell death and chlorella, which is applied in the biological field, can solve the problems of complex preparation of hydrogenase simulants, troublesome extraction process of natural enzymes, and difficult storage, and achieve the effects of long hydrogen production time, simple preparation method, and reduced pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

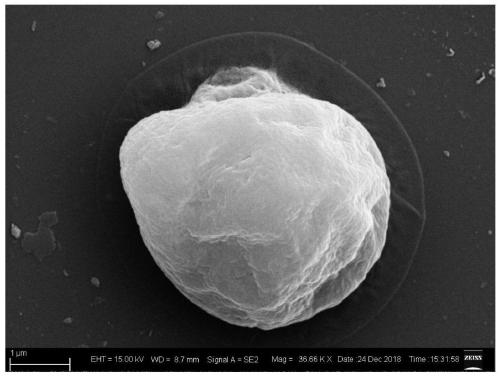

[0022] Specific implementation mode 1: In this implementation mode, a method for maintaining continuous hydrogen production after the death of Chlorella cells is specifically carried out according to the following steps:

[0023] 1. Cultivation of Chlorella pyrenoidosa cells: Select Chlorella pyrenoidosa as a biological template, and use BG-11 medium to cultivate in a light incubator with a temperature of 25-30°C under continuous light of 1200-4800LUX. Coating is performed when the number of chlorella cells reaches the logarithmic growth phase to obtain chlorella pyrenoidosa cells in the logarithmic growth phase;

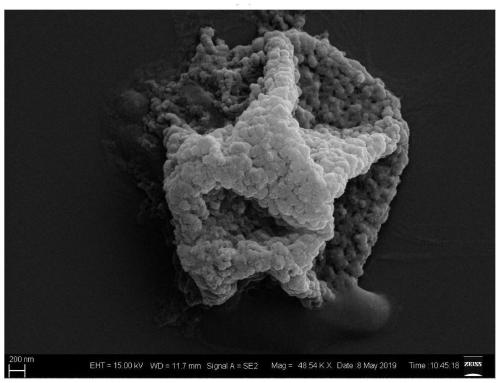

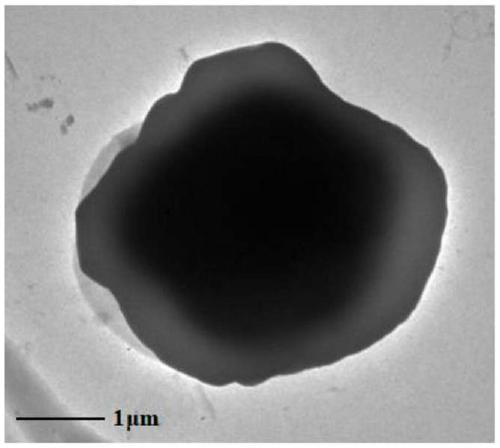

[0024] 2. Use deionized water to clean the chlorella pyrenoidosa cells in the logarithmic phase of growth, collect the cells by centrifugation, and add the collected cells to the ferric nitrate nonahydrate aqueous solution to obtain the cell solution; Stir for 20-40min under the condition of ~260r / min. After the reaction is completed, wash with deionized water and c...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that: the concentration of the ferric nitrate nonahydrate aqueous solution in step 2 is 1.2 mg / mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the OD value of the cell solution in Step 2 is 1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com