Dendrite etchant and corrosion method for large ingot modified in617 alloy

A etchant and alloy technology, which is applied to the dendritic etchant and its corrosion field of large ingot type modified IN617 alloy, can solve the problem of clear corrosion of the unmodified IN617 alloy, and achieve good corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

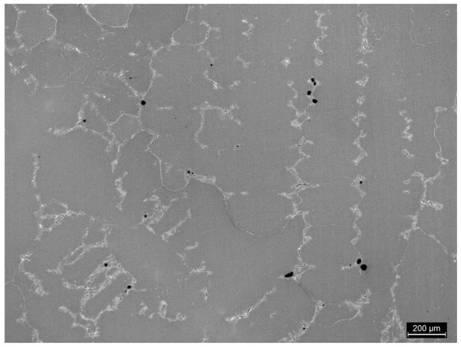

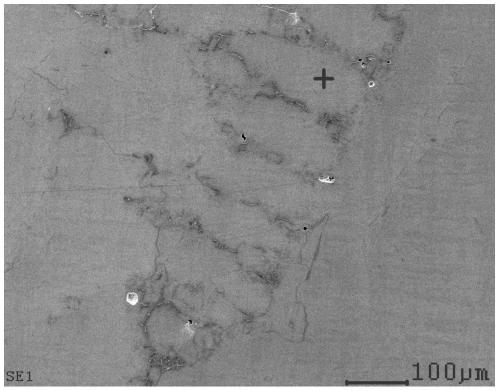

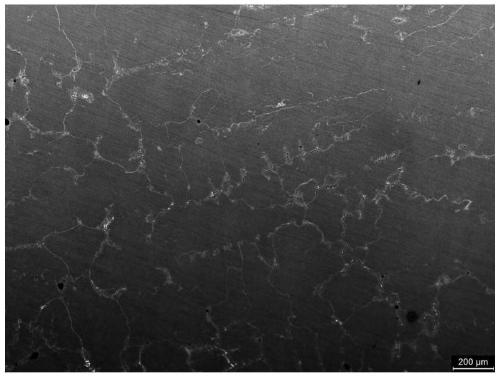

Image

Examples

Embodiment 1

[0036] This embodiment discloses a dendrite etchant for a large ingot modified IN617 alloy smelted by a triple process. The composition of the dendrite etchant is:

[0037]

[0038] In the formulation of the dendrite etchant provided in this example, using ethanol as a solvent can increase the reaction rate and ensure the uniformity of dendrite erosion. Therefore, ethanol has a certain effect of electrolytic polishing; and concentrated hydrochloric acid and concentrated nitric acid are mixed. It will generate more oxidizing nitrosyl oxide, whose molecular formula is NOCl, and nitrosyl oxide and Cl in the corrosive solution - Both are highly oxidizing, making them superior to traditionally used solutions in corroding dendrites.

[0039] In order to further ensure the corrosion effect of the dendrite etchant, the concentration of each component in the formula of the above dendrite etchant is respectively: the mass percent concentration of concentrated hydrochloric acid is 36%...

Embodiment 2

[0042]On the one hand, this embodiment provides a method for preparing a dendrite corrosive agent for a large ingot modified IN617 alloy smelted by a triple process. According to the above-mentioned composition ratio of the dendrite corrosive agent for the modified IN617 alloy, sequentially add Water, concentrated hydrochloric acid, ethanol and concentrated nitric acid were stirred evenly with a glass rod to prepare a dendritic etchant for a large ingot modified IN617 alloy. It should be noted that the dendritic etchant has the best effect when it is newly prepared, so it is best to prepare it and use it immediately.

[0043] On the other hand, this embodiment also provides a method for corroding the dendrite etchant of the large ingot type modified IN617 alloy smelted by the triple process, using the above-mentioned dendrite etchant of the large ingot type modified IN617 alloy, the method includes the following step:

[0044] S1. Prepare a test sample of modified IN617 alloy...

Embodiment 3

[0051] This embodiment discloses a dendritic etchant for a large ingot modified IN617 alloy smelted by a triple process. The dendrite etchant includes concentrated hydrochloric acid, concentrated nitric acid, water and ethanol; the components and volume contents of the dendrite etchant are:

[0052]

[0053] The concrete preparation steps of above-mentioned dendrite etchant are:

[0054] S1: Preparation of testing samples for modified IN617 alloy

[0055] Roughly grind, finely grind, polish, clean and dry the test sample; among them:

[0056] Put the sample on the sample grinding machine for coarse grinding and fine grinding: grind with 180#, 320#, 600#, 800#, 1200#, 2000# sandpaper respectively, add water to cool during the grinding process, and the scratches are in the same direction One of the grindings is completed immediately, and when the next grinding is performed, the grinding direction is perpendicular to the scratch direction of the previous one, and the grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com