Preparation method of flexible conductive ceramic fiber membrane

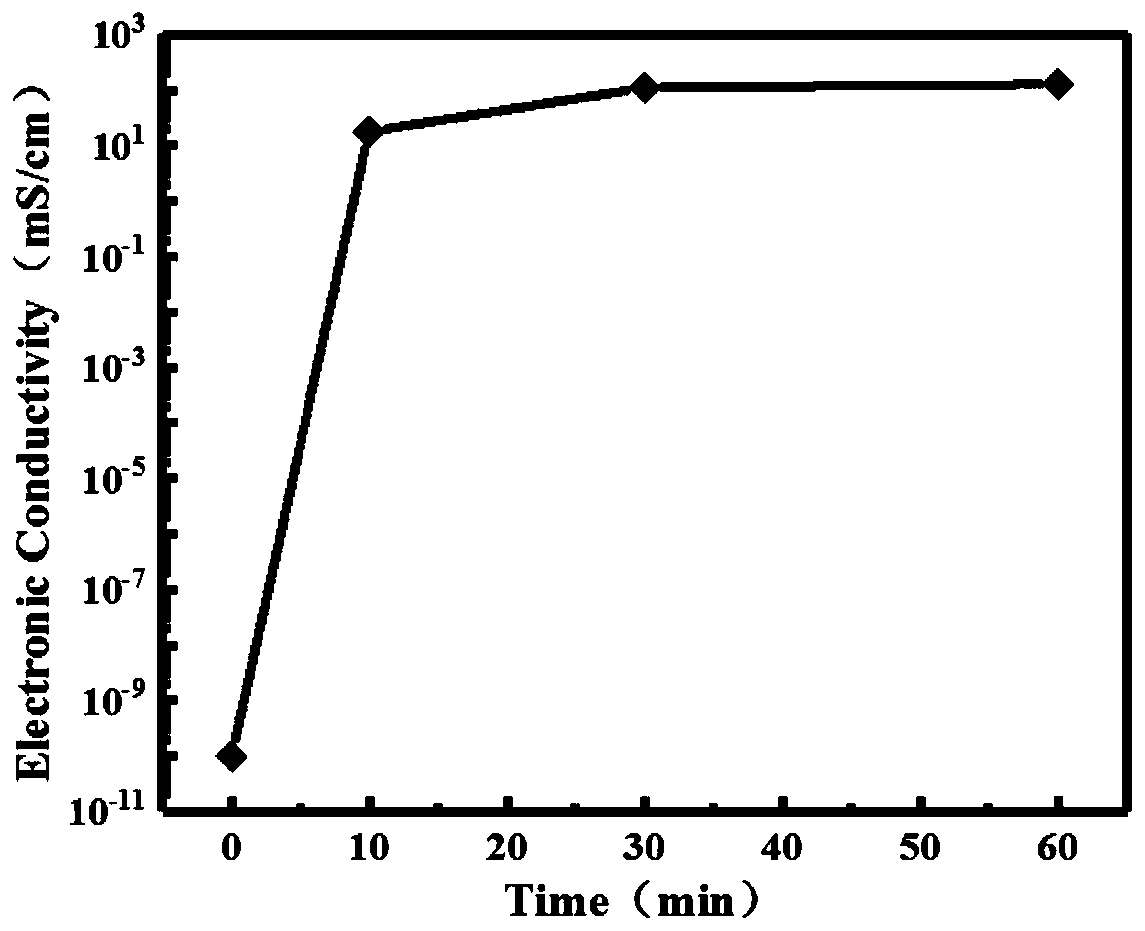

A ceramic fiber, flexible and conductive technology, which is applied in fiber processing, heating/cooling fabrics, textiles and papermaking, etc., can solve the problems of expensive and increased preparation costs, achieve low cost, short cycle time, and improve electronic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing a flexible conductive titanium dioxide ceramic fiber membrane, the specific steps are:

[0047] (1) Configure TiO composed of titanium source, polymer and solvent 2 Precursor solution: Dissolve 0.5g of high-molecular polymer polyethylene oxide (Aladdin, P101341) in 4g of glacial acetic acid at 30°C, stir for 120min, then add 8g of ethanol and 1.5g of isopropyl titanate to the solution, Stir to form a well-mixed TiO 2 precursor solution.

[0048] (2) the resulting TiO 2 The precursor solution is electrospun. Under the action of an electric field, the charge repulsion on the surface of the charged droplet exceeds its surface tension, forming a jet from the surface and going through a series of processes such as stretching, solvent volatilization, and polymer solution jet solidification, and finally deposited on the On the receiving substrate, the precursor nanofiber film is obtained. During electrospinning, a constant temperature thermal field of...

Embodiment 2

[0054] A method for preparing a flexible conductive titanium dioxide ceramic fiber membrane, the specific steps are:

[0055] (1) Configure TiO composed of titanium source, polymer and solvent 2 Precursor solution: Dissolve 0.5g of high-molecular polymer polyethylene oxide (Aladdin, P101341) in 4g of glacial acetic acid at 30°C, stir for 120min, then add 8g of ethanol and 1.5g of isopropyl titanate to the solution, Stir to form a well-mixed TiO 2 precursor solution.

[0056] (2) the resulting TiO 2 The precursor solution is electrospun, and the precursor nanofiber film is electrospun. A constant temperature thermal field of 25°C is applied in the spinning interval and the temperature of the receiving device is controlled to 25°C; the parameters of the electrospinning are: relative humidity 45% , the perfusion speed is 3mL / h, the voltage is 20kV, the distance between the receiving device and the spinneret is 20cm, the rotating speed of the receiving device is 60n / min, and th...

Embodiment 3

[0063] A method for preparing a flexible conductive oxide ceramic fiber membrane, the specific steps are:

[0064] (1) Configure SnO composed of tin source, polymer and solvent 2 Precursor solution: Dissolve 2g of high-molecular polymer polyvinyl alcohol (Aladdin, polyvinyl alcohol 1788 type) in 18g of water at 30°C, stir at 90°C for 120min, cool to room temperature, take 10g of PVA solution, and slowly add to the solution Add 1g SnCl to 4 ·5H 2 O, add water and stir at the same time, adjust the mass fraction of PVA to 6%, and form a uniformly mixed SnO 2 Precursor solution;

[0065] (2) The resulting SnO 2 The precursor solution is electrospun. Under the action of an electric field, the charge repulsion on the surface of the charged droplet exceeds its surface tension, forming a jet from the surface and going through a series of processes such as stretching, solvent volatilization, and polymer solution jet solidification, and finally deposited on the On the receiving sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com