Blending modified polyvinylidene fluoride membrane and preparation method and application

A polyvinylidene fluoride membrane, blending modification technology, applied in the field of microporous membrane, can solve the problem of unsatisfactory anti-fouling performance of membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

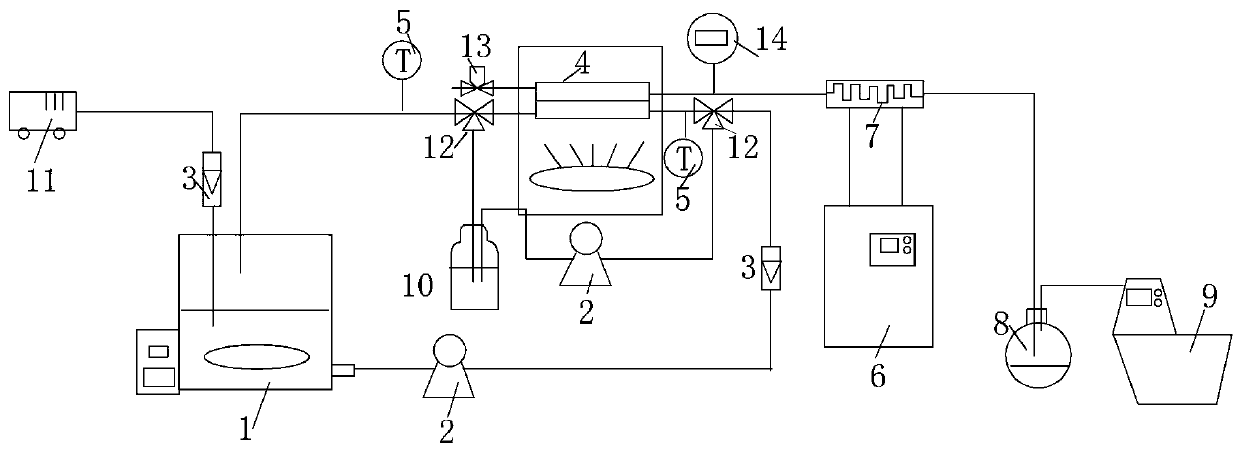

[0035] A preparation method of a blended modified polyvinylidene fluoride film, the preparation method comprising:

[0036] (1) Preparation of casting liquid: adding titanium dioxide, graphene and porogen to polar solvent and mixing, then adding polyvinylidene fluoride, and mixing evenly to obtain casting liquid;

[0037] (2) Preparation of the blended matrix film: after scraping the film casting liquid, it is cured in a coagulation bath, soaked and air-dried to obtain a blended matrix film.

[0038] Step (1) The casting solution includes 10-15wt% polyvinylidene fluoride polymer, 1-5wt% porogen, 0.1-0.5wt% graphene, 2.8-7wt% titanium dioxide, and the balance is For polar solvents, the above substances add up to 100%.

[0039] The porogen is selected from lithium chloride, polyethylene glycol or polypyrrolidone, and the polar solvent is selected from N,N-dimethylacetamide.

[0040] The specific steps of step (1) are to add titanium dioxide, graphene and porogen into a polar sol...

Embodiment 1

[0053] Example 1: Preparation of the blend-modified polyvinylidene fluoride film of the present invention;

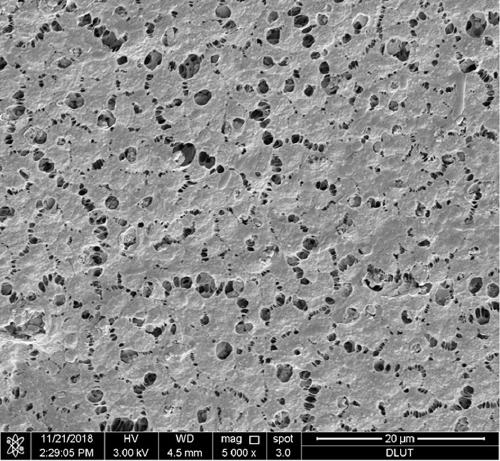

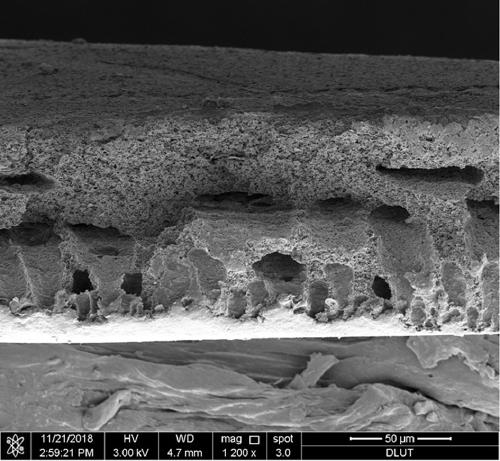

[0054] Graphene / TiO 2 - Preparation of PVDF composite membrane: First, weigh 0.05g of graphene, 2.5g of titanium dioxide and 1.5g of lithium chloride, and put the weighed drugs into 43.5g of N,N-dimethylacetamide (DMAc) solvent. Shake the solution well into an ultrasonic cleaner, set the ultrasonic power to 400W, the temperature to 40°C, and ultrasonically disperse for 2h. 6.5g of PVDF was added under stirring, and the stirring temperature was set to 60°C, and a uniform casting solution was obtained after stirring for 12 hours. Let stand for 24h to remove air bubbles in the casting solution. Cast the prepared casting solution on a smooth and clean glass plate, scrape it into a thin layer with a thickness of 200 μm with a self-made doctor blade (glass rod), and then put the glass plate into a 40wt% ethanol aqueous solution. Replace and separate the phases. After the m...

Embodiment 2

[0055] Example 2: Preparation of the blend-modified polyvinylidene fluoride film of the present invention;

[0056] Graphene / TiO 2 - Preparation of PVDF composite membrane: First, weigh 0.15g of graphene, 2.5g of titanium dioxide and 1.5g of lithium chloride, and put the weighed drugs into 43.5g of N,N-dimethylacetamide (DMAc) solvent. Shake the solution well into an ultrasonic cleaner, set the ultrasonic power to 400W, the temperature to 40°C, and ultrasonically disperse for 2h. 6.5g of PVDF was added under stirring, and the stirring temperature was set to 60°C, and a uniform casting solution was obtained after stirring for 12 hours. Let stand for 24h to remove air bubbles in the casting solution. Cast the prepared casting solution on a smooth and clean glass plate, scrape it into a thin layer with a thickness of 200 μm with a self-made doctor blade (glass rod), and then put the glass plate into a 40wt% ethanol aqueous solution. Replace and separate the phases. After the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average surface roughness | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com