Loaded catalyst for propane dehydrogenation to propylene and preparation method thereof

A supported catalyst, propane dehydrogenation technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc. Poisoning and deactivation problems, to achieve excellent catalytic stability, improve stability and service life, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation of La by precipitation method 2 o 3 6Al 2 o 3 Carrier, weigh lanthanum nitrate and aluminum nitrate according to the atomic ratio of La: Al in the chemical formula and dissolve them in deionized water. After stirring for 25 minutes, slowly add an aqueous solution of ammonium carbonate to form a milky white precipitate. After continuing to stir for 120 minutes, filter and wash the filtered solid The material was dried overnight in a 100°C oven. The dried powder was calcined in a muffle furnace at 1000°C for 3 hours to obtain a white powder with a specific surface area of 120m 2 / g.

Embodiment 2

[0031] The La prepared by embodiment 1 2 o 3 6Al 2 o 3 The carrier is used in the impregnation method to synthesize loaded Cr 2 o3 catalyst. Weigh a certain amount of chromium nitrate and dissolve it in deionized water, add La 2 o 3 6Al 2 o 3 Carrier, where Cr 2 o 3 The loading amount is 15wt%. Heat and stir until the solution evaporates to dryness, and dry the solid material in an oven at 100°C overnight. The dried powder was calcined in a muffle furnace at 500° C. for 6 hours to obtain a light green powder supported catalyst.

Embodiment 3

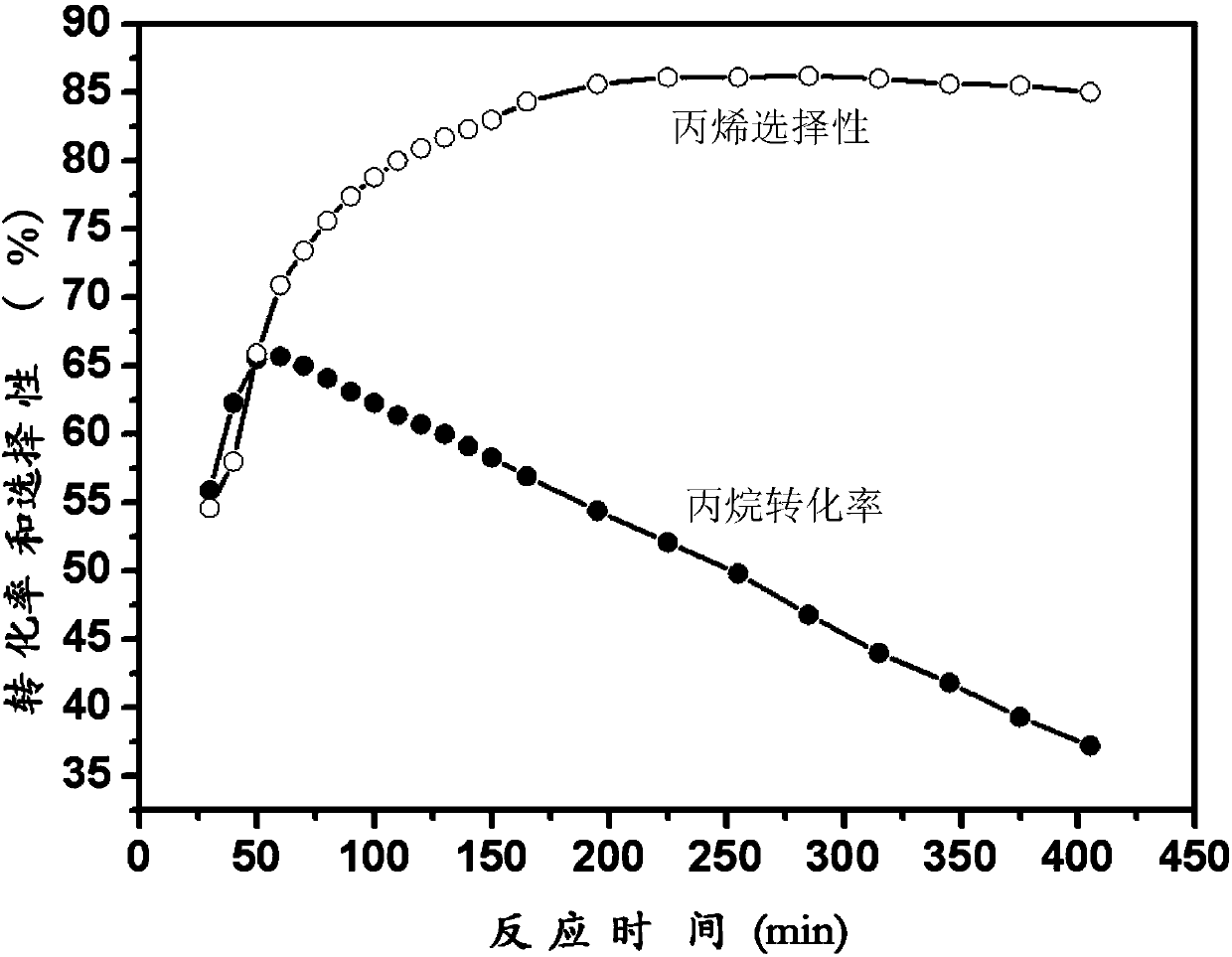

[0033] The loaded Cr prepared by embodiment 2 2 o 3 (15wt%) / La 2 o 3 6Al 2 o 3 The catalyst is used in the direct dehydrogenation of propane to propylene. Weigh 1g of 20-30 mesh catalyst, the reaction raw material gas is pure propane, the reaction pressure is normal pressure, the reaction temperature is 600°C, and the reaction space velocity is 320ml·g -1 h -1 . The result of the reaction is as figure 1 shown. With industrial Cr in comparative example 1 2 o 3 / Al 2 o 3 Catalyst comparison ( Figure 5 ), the propane conversion and propylene selectivity of the catalyst are close to those of industrial catalysts, showing high propane dehydrogenation activity and selectivity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com