Rotatable magnetic nano chain supported palladium nanoparticle catalyst and preparation method thereof

A magnetic nanochain and nanochain technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low recycling rate, easy agglomeration, difficult separation of catalysts, etc., to achieve growth strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

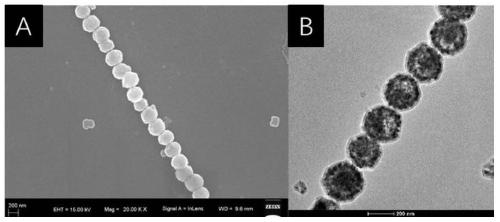

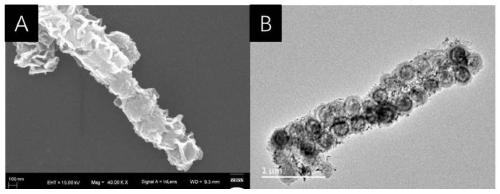

[0039] Step 1. Preparation of core-shell Fe by distillation-precipitation polymerization induced by external magnetic field 3 o 4 @P(DVB-MAA) magnetic nanochain. Disperse 0.026g of magnetic microspheres, 0.072g of divinylbenzene and 0.271g of methacrylic acid in 80mL of acetonitrile, and then add 7.5mg of AIBN after ultrasonication for 1 hour. React for 1 hour, collect the product by magnetic separation, and wash the product 3 times with absolute ethanol and deionized water, respectively, to obtain the core-shell Fe 3 o 4 @P(DVB-MAA) magnetic nanochain.

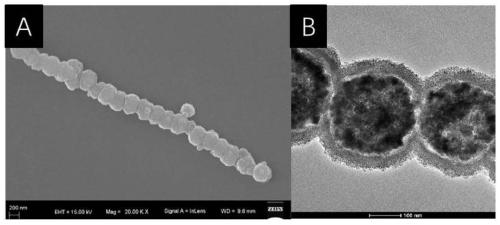

[0040] Step 2, the obtained Fe 3 o 4 @P(DVB-MAA) magnetic nanochains were dispersed in a mixed solvent containing 50mL of absolute ethanol and 6.25mL of deionized water, and 2mL of ammonia water was added under mechanical stirring at 280r / min. After stirring for 1 hour, 0.15mL of TEOS was added in sequence React with 0.03mL of octadecyltrimethoxysilane overnight at room temperature, perform magnetic separation, wash wit...

Embodiment 2

[0044] Step 1. Preparation of core-shell Fe by distillation-precipitation polymerization induced by external magnetic field 3 o 4@P(DVB-MAA) magnetic nanochain. Disperse 0.022g of magnetic microspheres, 0.071g of divinylbenzene and 0.273g of methacrylic acid in 80mL of acetonitrile, and then add 7.5mg of AIBN after ultrasonication for 1 hour. After the dissolution is complete, transfer the mixed solution into a three-necked flask, and react in a water bath at 80°C After 1 hour, the product was collected by magnetic separation, and the product was washed 4 times with absolute ethanol and deionized water, respectively, to obtain the core-shell Fe 3 o 4 @P(DVB-MAA) magnetic nanochain.

[0045] Step 2, the obtained Fe 3 o 4 @P(DVB-MAA) magnetic nanochains were dispersed in a mixed solvent containing 50mL of absolute ethanol and 6.25mL of deionized water, and 2mL of ammonia water was added under mechanical stirring at 280r / min. After stirring for 1 hour, 0.15mL of TEOS was add...

Embodiment 3

[0049] Step 1. Preparation of core-shell Fe by distillation-precipitation polymerization induced by external magnetic field 3 o 4 @P(DVB-MAA) magnetic nanochain. Disperse 0.02g of magnetic microspheres, 0.07g of divinylbenzene and 0.27g of methacrylic acid in 80mL of acetonitrile, and then add 7.5mg of AIBN after ultrasonication for 1 hour. After the dissolution is complete, transfer the mixed solution into a three-necked flask, and react in a water bath at 80°C 1h, the product was collected by magnetic separation, and the product was washed 3 to 4 times with absolute ethanol and deionized water, respectively, to obtain the core-shell Fe 3 o 4 @P(DVB-MAA) magnetic nanochain.

[0050] Step 2, the obtained Fe 3 o 4 @P(DVB-MAA) magnetic nanochains were dispersed in a mixed solvent containing 50mL of absolute ethanol and 6.25mL of deionized water, and 2mL of ammonia water was added under mechanical stirring at 280r / min. After stirring for 1 hour, 0.15mL of TEOS was added in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com