Preparation method and application of SSZ-13 molecular sieve

A molecular sieve and crystallization reaction technology, applied in the field of molecular sieves, can solve the problems of destroying the crystal skeleton structure, reducing the crystallinity of SSZ-13 molecular sieve, and complicated synthesis steps, achieving high and low carbon olefin selectivity, shortening time and cost, and low product. Effect of carbon rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of SSZ-13 molecular sieve, it comprises the steps:

[0021] Step (a), dissolving sodium hydroxide, aluminum source, silicon source and template in water to obtain mixture 1, in said mixture 1, the moles of said water, sodium hydroxide, aluminum source, silicon source and template The ratio is (30~50):(0.1~0.3):(0.02~0.01):1:(0.1~0.3).

[0022] Wherein, the aluminum source is selected from at least one of aluminum isopropoxide, activated alumina, aluminum isopropoxide, and pseudo-boehmite; the silicon source is selected from silica sol, tetraethyl orthosilicate, silicic acid At least one of sodium and fumed silica. The templating agent is an organic amine, for example, N,N,N-trimethyl-1-adamantyl ammonium hydroxide. Specifically, weigh a predetermined amount of water, aluminum source, silicon source, sodium hydroxide and template agent, add water, aluminum source, silicon source, sodium hydroxide and template agent in...

Embodiment 1

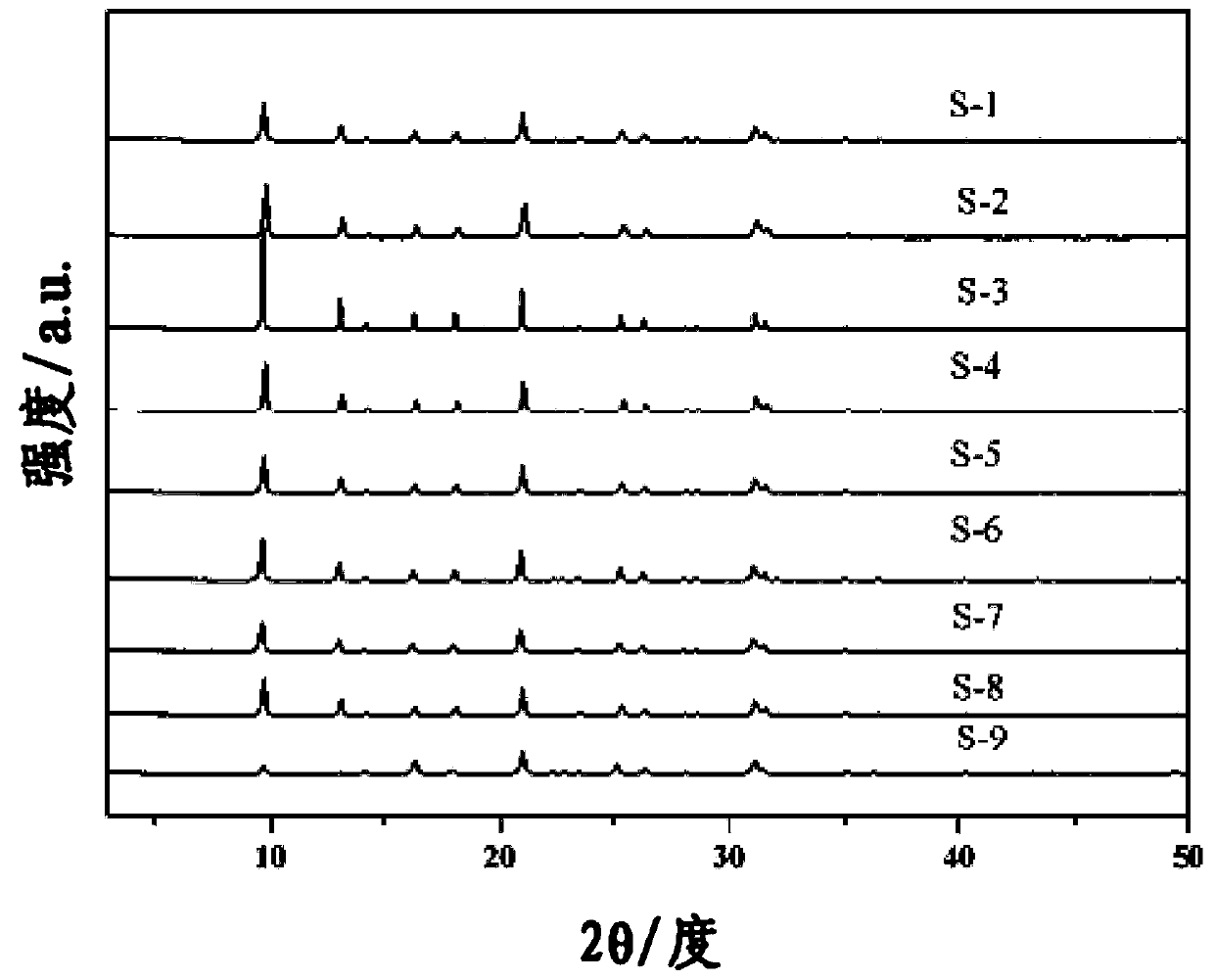

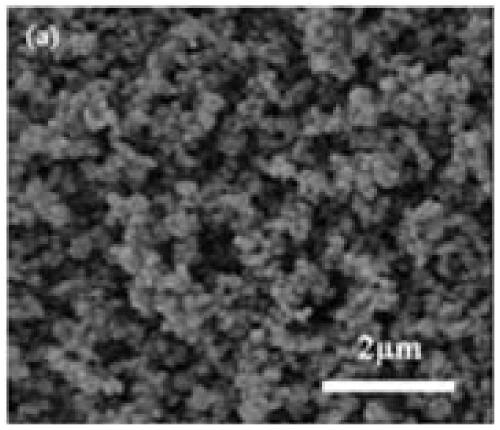

[0038] N,N,N-trimethyl-1-adamantyl ammonium hydroxide, sodium hydroxide, aluminum isopropoxide, fumed silica, water according to the molar ratio TMAdaOH:Na 2 O: Al 2 o 3 :SiO2 2 :H 2 Mix O=0.2:0.1:0.04:1:44, stir at 30°C for 2 hours to form mixture 1, add 1g of anionic polyacrylamide with a molecular weight of 2 million to every 100g of mixture 1 to form mixture 2, and age at room temperature 24h, put it into a stainless steel autoclave with polytetrafluoroethylene, crystallize at 175°C for 120h, wash, dry at 110°C, and roast at 550°C to obtain SSZ-13 molecular sieve (sample number S-1). Its XRD pattern is shown in figure 1 , SEM image see figure 2 . Depend on figure 2It can be seen from the SEM image that the SSZ-13 molecular sieve obtained in this embodiment is cubic and uniform in size, about 100 nm.

Embodiment 2

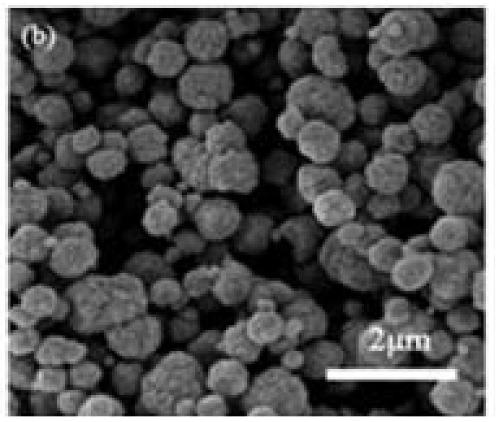

[0044] N,N,N-trimethyl-1-adamantyl ammonium hydroxide, sodium hydroxide, aluminum isopropoxide, fumed silica, water according to the molar ratio TMAdaOH:Na 2 O: Al 2 o 3 :SiO2 2 :H 2 Mix O=0.2:0.1:0.04:1:44, stir at 30°C for 2 hours to form mixture 1, add 1g of anionic polyacrylamide with a molecular weight of 2 million to every 100g of mixture 1 to form mixture 2, and age at room temperature 24h, put it into a stainless steel autoclave with polytetrafluoroethylene, then crystallize in a conventional reactor at 150°C for 120h, wash, dry at 110°C, and roast at 550°C to obtain SSZ-13 molecular sieve (sample number S -4). Its XRD pattern is shown in figure 1 , SEM image see Figure 5 . Depend on Figure 5 It can be seen from the SEM image that the SSZ-13 molecular sieve obtained in this example is ellipsoidal in shape and uniform in size, about 390 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com