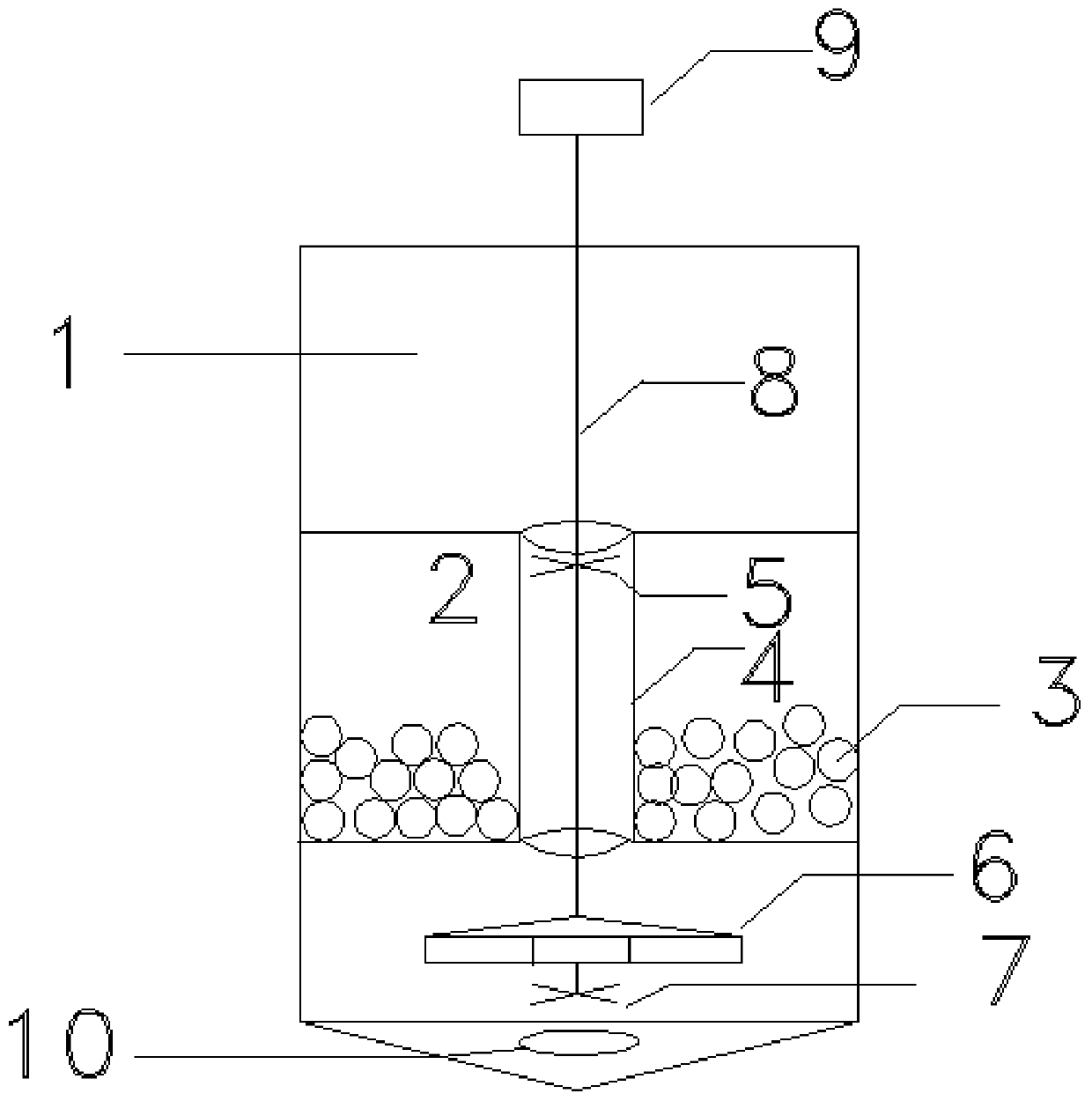

Fermentation reactor for preparing citric acid from immobilized Aspergillus niger and a method thereof

A reactor, the technology of Aspergillus niger, which is applied in the field of fermentation reactors for immobilizing Aspergillus niger to produce citric acid, can solve the problems of unfavorable separation and purification of products in the later stage of fermentation, limited number of times of repeated use of carriers, and expansion of industrial-scale production, etc. The effect of mass and heat transfer performance, complete consumption of residual sugar, and shortening of fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Immobilized culture, fermentation after embodiment 1 Aspergillus niger spore expansion

[0036] Liquefaction sugar production: 11kg corn flour is mixed with 33 liters of water, the pH is 5.8-6.0, add liquefaction enzyme 16U / g corn flour, liquefy at 65°C for 45 minutes, heat up to 95°C for 45 minutes, and DE reaches 25%. Keep 8L of the returned material with slag for later use, and the remaining liquefied mash is subjected to centrifugation, and the supernatant liquid is for later use.

[0037]Seed preparation: Prepare 5L of seed solution with slag-returned material (using 10L seed tank, T&J-Btype×2, DBeer Bioengineering (Shanghai) Co., Ltd.), total sugar 120g / L, inoculated spores 1g, ventilation volume 400L / h, the rotation speed is 500r / min, the temperature is 36°C and cultivated for about 26 hours, the pH is below 2.5, the acidity is 1.5-2.0, and the bacteria balls are uniform.

[0038] Immobilized culture and fermentation: after the seed culture is finished, insert ...

Embodiment 2

[0039] Carry out immobilized culture, fermentation after embodiment 2 Aspergillus niger spore expansion culture

[0040] Insert the cultured spores into an immobilized fermenter equipped with a fermentation medium at a rate of 0.2g / L (the immobilized carrier is porous polyurethane). The first batch is equivalent to the fixed culture process, and the preparation of the fermentation medium and the culture conditions are the same as the implementation Example 1, discharge the fermentation broth until the reducing sugar drops below 1g / L, and add new fermentation medium again. 12 batches are run continuously, the average fermentation time is 46 hours, and the average sugar-acid conversion rate reaches 95.5%.

Embodiment 3

[0041] The influence of embodiment 3 different carrier sizes on immobilization and fermentation

[0042] Insert 0.2g / L of the cultured spores into an immobilized fermenter equipped with a fermentation medium (the carrier is activated carbon filter cotton), and investigate different sizes (1cm×1cm×1cm, 2cm×2cm×1cm, 2.5cm× 2.5cm * 2.5cm) on Aspergillus niger immobilization and fermentation influence, each fermentation 3 batches (the first batch is equal to the fixed culture process, does not count in fermentation batch), fermentation medium and culture condition are with embodiment 1. The results showed that the second fermentation had the best effect, and the acid production rates were 3.16g / L / h, 3.33g / L / h, and 2.85g / L / h, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com