A silicon carbide planar polishing method and device with synergistic effects of chemical pretreatment and dielectrophoresis

A polishing device and a technology of dielectrophoresis, which are applied in chemical instruments and methods, machine tools for surface polishing, after treatment, etc., can solve the problems of reduced energy attached to abrasive particles, uneven pressure distribution, and low processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

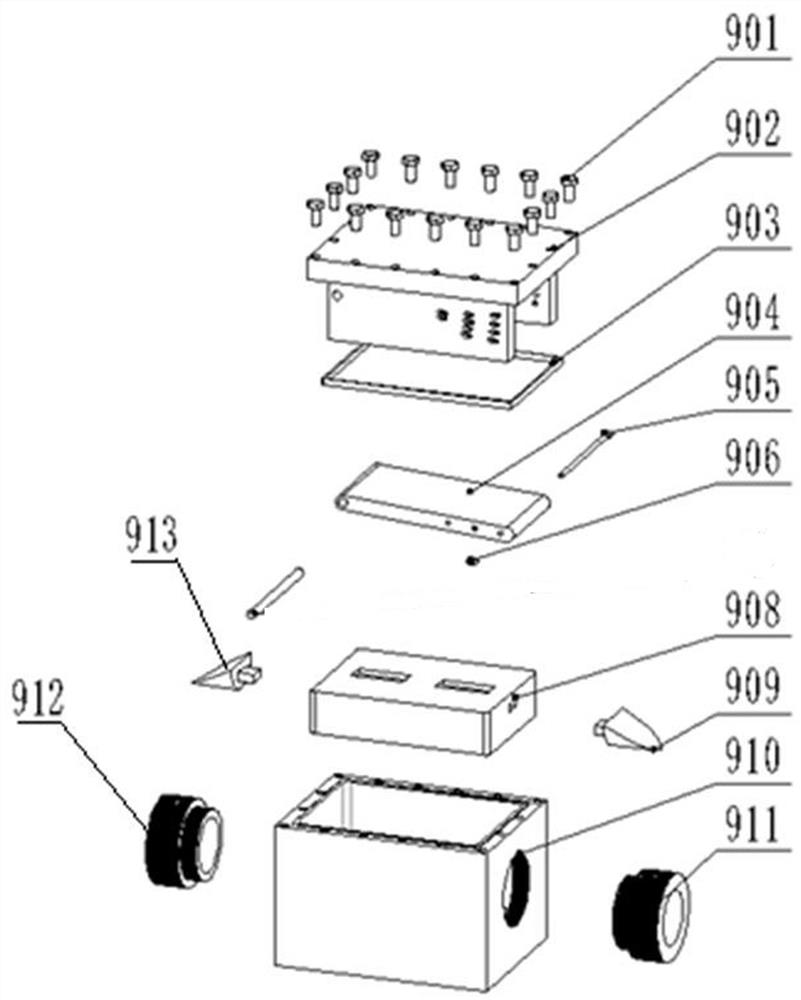

[0031] The following describes the present invention in detail based on the accompanying drawings and preferred embodiments. The purpose and effects of the present invention will become more apparent. The following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

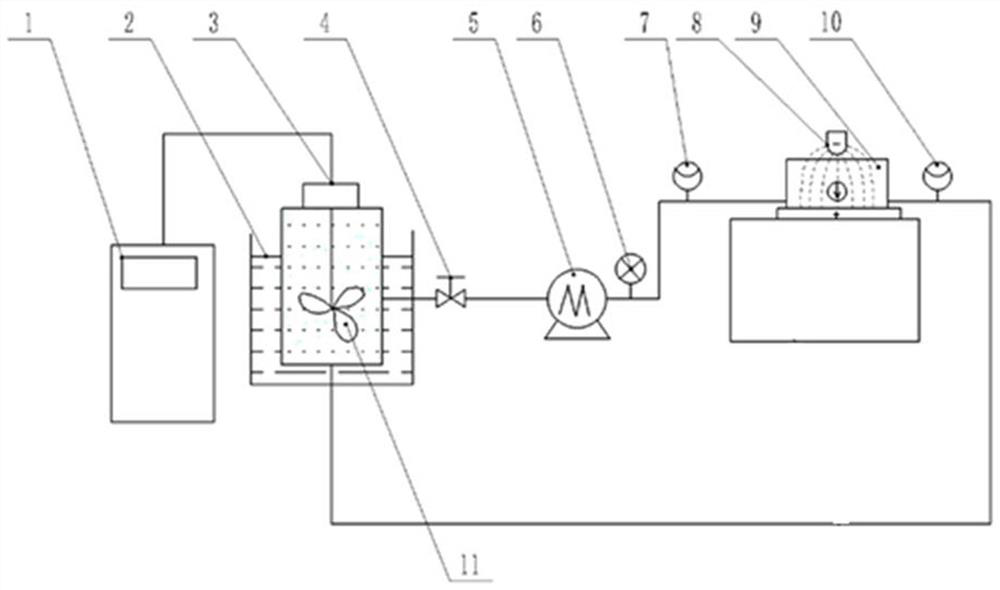

[0032] A method for polishing a silicon carbide plane with synergistic effects of chemical pretreatment and dielectrophoresis, the method includes the following steps:

[0033] S1: Put the silicon carbide workpiece in the pretreatment workpiece groove, and use negative compression material to seal, only expose the plane to be polished;

[0034] S2: Put the silicon carbide wafer treated by S1 into Fenton's reagent for pretreatment, so that a silicon dioxide corrosion layer is formed on the surface of the sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com