Integrated advanced treatment reactor for restaurant waste water

A technology for advanced treatment of catering wastewater, applied in water/sewage treatment, biological water/sewage treatment, multi-stage water/sewage treatment, etc. The problem of land area and other issues can be achieved to reduce the occupied area, increase the load of sewage treatment, and achieve the effect of high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

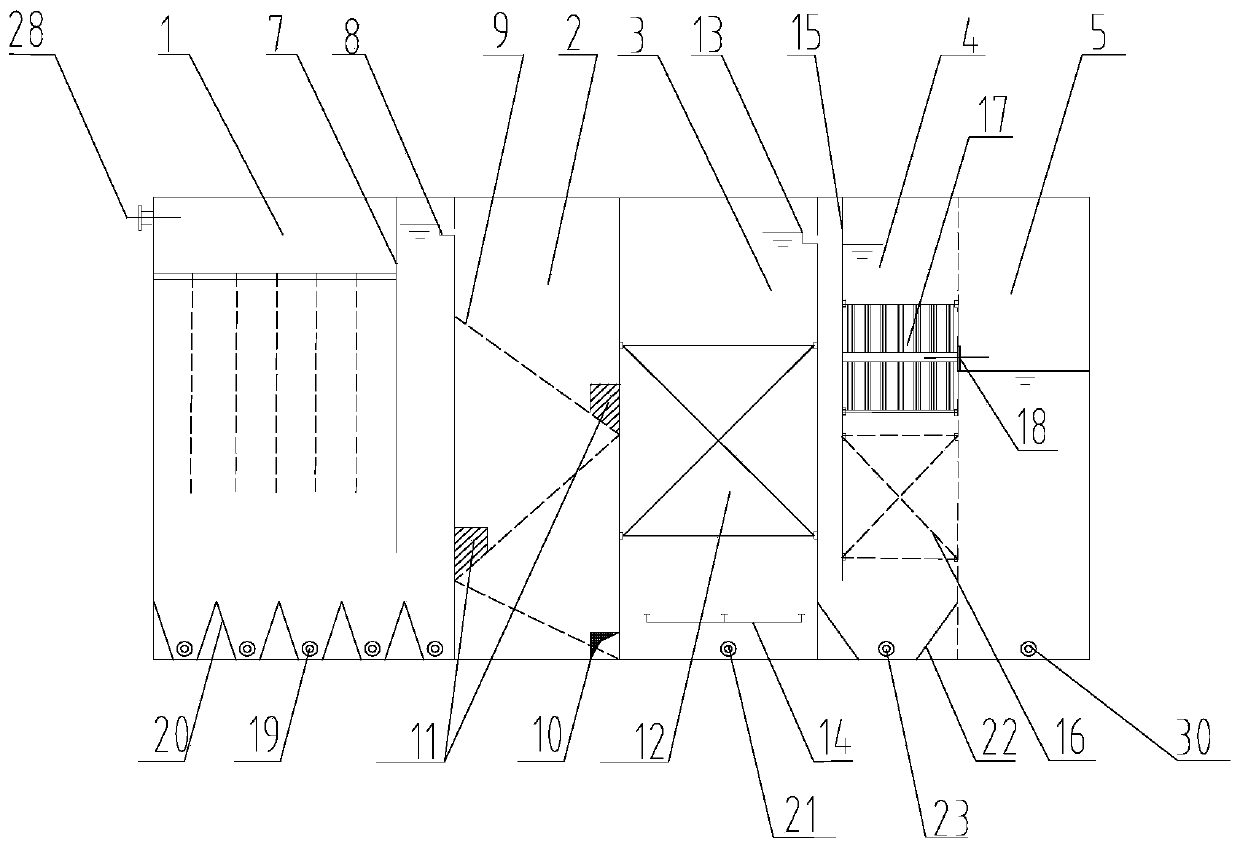

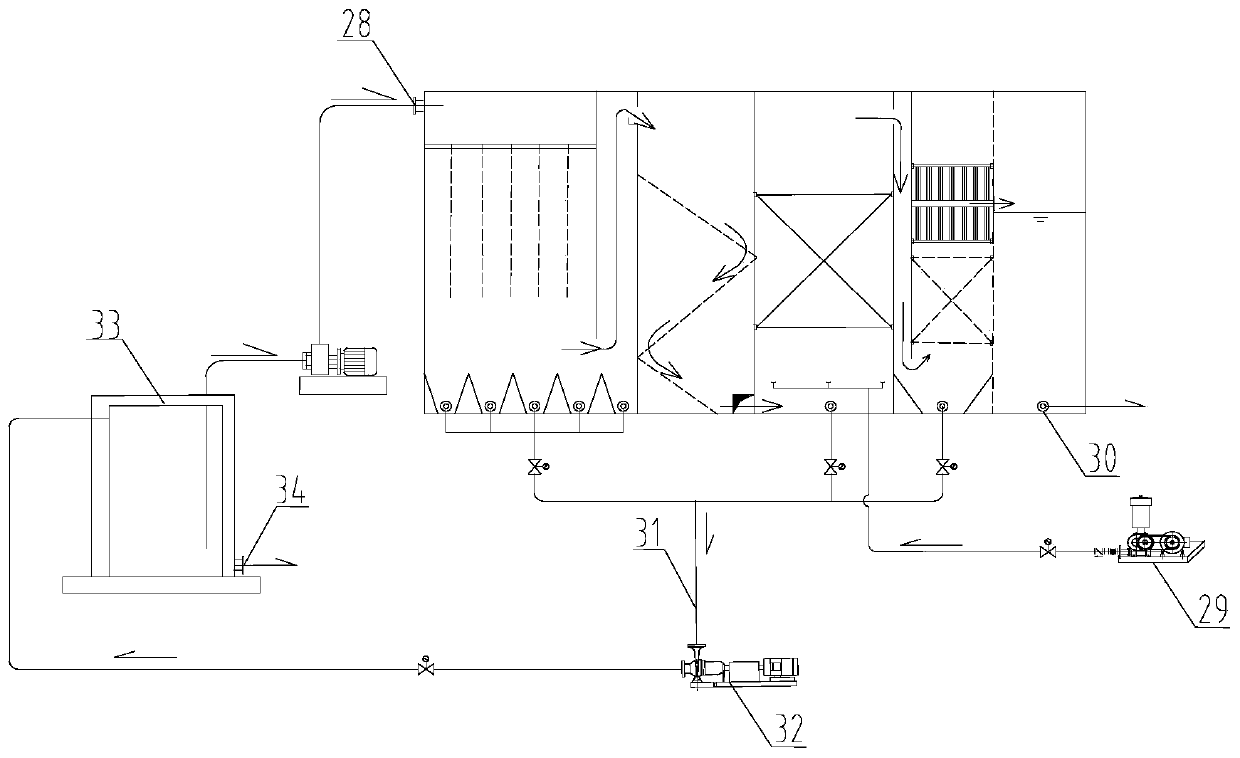

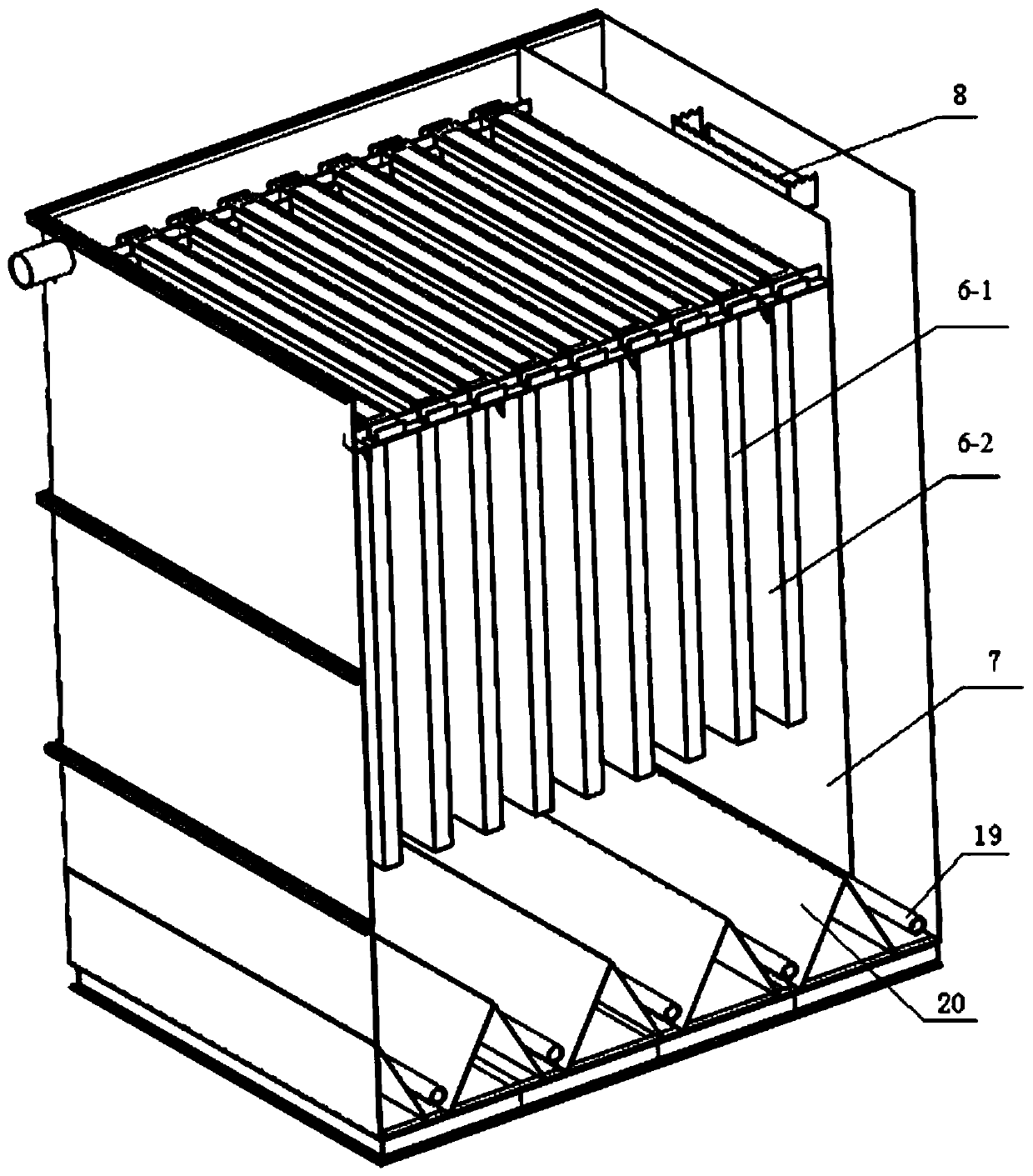

Method used

Image

Examples

Embodiment 1

[0039] Using this device to treat catering wastewater in a shopping center in Beijing

[0040] Water quality: COD cr 2000~4000mg / L, BOD 5 1500~2500mg / L, SS 100~250mg / L, ammonia nitrogen 20~40mg / L, pH 6.0~8.0

[0041] Its processing steps are:

[0042] 1) Catering sewage is pumped to the electroflocculation tank 1 through the grease trap, the input AC is 220V~110V, the working voltage is 24V, the current is 10A~50A, the electrodes can be Fe, Al, the time interval between yin and yang is 3 hours, and the hydraulic retention Time 0.75h;

[0043] 2) The sedimented sludge at the bottom of the electrocoagulation tank is discharged;

[0044] 3) The supernatant in the electrocoagulation precipitation area overflows into the facultative tank 2, and the anaerobic microorganisms are in the state of hydrolysis and acid production, converting insoluble organic matter into soluble organic matter, and the hydraulic retention time is 3.5h;

[0045] 4) The muddy water in the facultative o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com