Small molecule alginic acid microbial fertilizer

A microbial fertilizer and alginic acid technology, applied in organic fertilizers, ammonium salt fertilizers, fertilizer mixtures, etc., can solve problems such as the destruction of active nutrients, and achieve the effects of easy absorption and utilization, rich sources of raw materials, and rich endogenous active substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

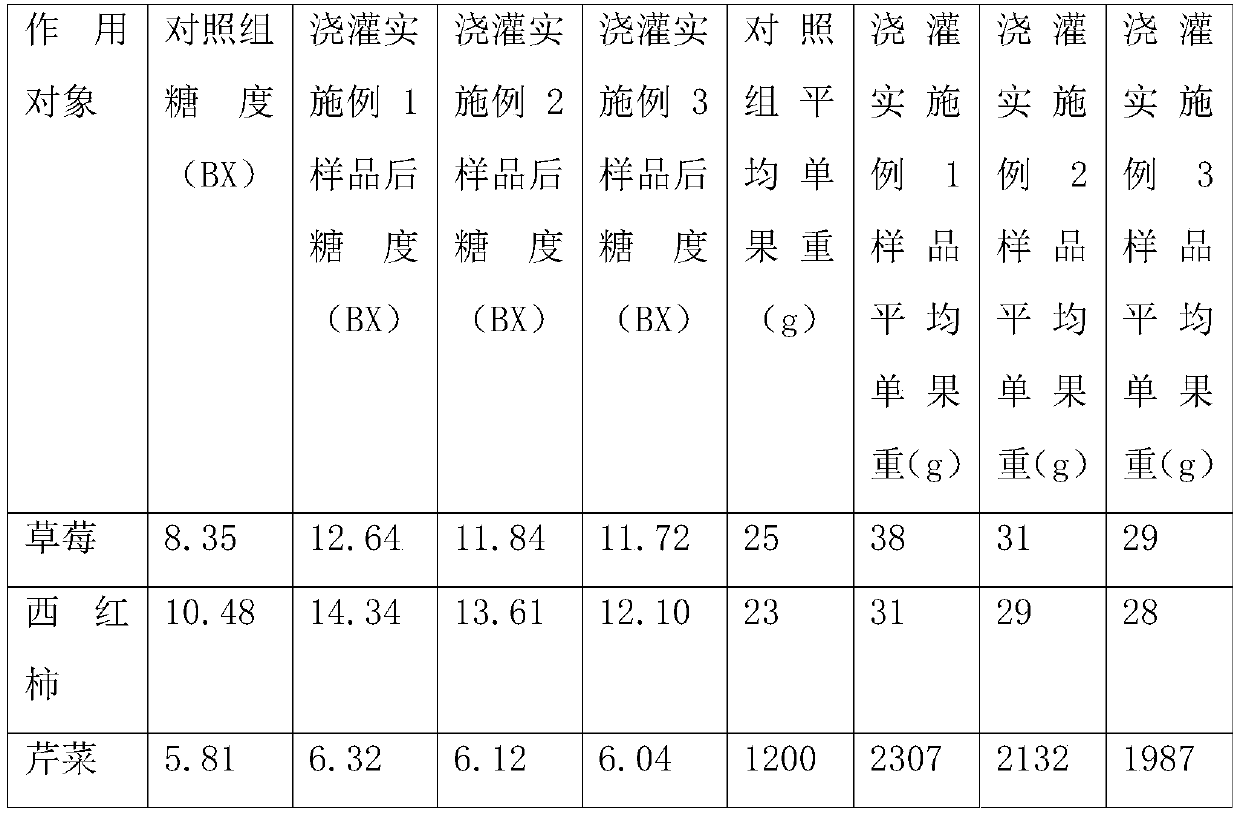

Examples

Embodiment 1

[0031] (1) Take the dry Ascophyllum nodosum raw material and wash it with water to remove impurities such as salt and sand grains on the surface.

[0032] (2) Dry the washed seaweed, take 200g and grind it into powder, add water and stir until it becomes a paste, and obtain seaweed slurry; the amount of water added is 15 times of the dry weight of seaweed.

[0033] (3) Put the uniformly stirred seaweed pulp into the incubator, add 0.4g of pectinase and 0.8g of cellulase, control the temperature at 28° C., and hold the temperature for 36 hours to carry out the initial reaction.

[0034] (4) Adjust the temperature of the initially reacted product to 55°C, adjust the pH value to 6.8, and then add 4g of compound enzyme preparation, which is composed of alginate lyase, protease and chitinase, and the alginate cleavage The mass ratio of enzyme, protease and chitinase was 10:2:1, and the enzymolysis was continued for 7 hours.

[0035] (5) The liquid obtained by enzymatic hydrolysis ...

Embodiment 2

[0039] (1) Take dry Ascophyllum nodosum and kelp mixed seaweed material with a mass ratio of 1:1, wash with water, and remove impurities such as salt and sand grains on the surface.

[0040] (2) Dry the washed seaweed, take 200g and grind it into powder, add water and stir until it becomes a paste, and obtain seaweed slurry; the amount of water added is 20 times of the dry weight of seaweed.

[0041] (3) Put the uniformly stirred seaweed pulp into the incubator, add 0.8g of pectinase and 1.2g of cellulase, control the temperature at 28° C., and keep the holding time at 36 hours to carry out the initial reaction.

[0042] (4) Adjust the temperature of the initially reacted product to 50° C., adjust the pH value to 6.8, add 4 g of compound enzyme preparation, and continue enzymatic hydrolysis for 10 h. The compound enzyme preparation is composed of alginate lyase, pectinase and cellulase, and the mass ratio of alginate lyase, pectinase and cellulase is 10:1:2.

[0043] (5) The ...

Embodiment 3

[0047] (1) Take dry ascophyllum nodosum and wakame seaweed in a mass ratio of 1:2 and wash with water to remove impurities such as salt and sand grains on the surface.

[0048] (2) Dry the washed seaweed, take 200g and grind it into powder, add water and stir until it becomes a paste, and obtain seaweed slurry; the amount of water added is 15 times of the dry weight of seaweed.

[0049] (3) Put the evenly stirred seaweed pulp into the incubator, add 0.8 protein and 0.4 g hemicellulase, control the temperature at 28° C., and keep the holding time at 36 hours to carry out the initial reaction.

[0050] (4) Adjust the temperature of the initially reacted product to 40° C., adjust the pH value to 6.8, add 4 g of compound enzyme preparation and 0.2 g of protease digestion inhibitor, and continue enzymolysis for 5-10 h; the compound enzyme preparation is composed of It consists of alginate lyase, hemicellulase and pectinase, and the mass ratio of alginate lyase, hemicellulase and pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com