Preparation method of two-dimensional carbide crystal-based polyimide organic positive electrode material

A technology based on polyimide and two-dimensional carbide, which is applied in the fields of materials science and electrochemistry, can solve the problems of inability to obtain MXene, increase the diffusion resistance of lithium ions, and change the performance of MXene, and achieve good cycle stability and rate performance , Improve cycle stability, improve chemical reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The first step, preparation of two-dimensional carbide crystal-based polyimide composite material:

[0025] (1) Sonicate the N-methylpyrrolidone solution (5 mL) of MXene to form a uniformly mixed dispersion;

[0026] (2) Add 38.8 mg of naphthalene tetracarboxylic anhydride to the above dispersion, stir vigorously for half an hour, and the mass dosage ratio of added naphthalene tetracarboxylic anhydride to MXene is 2:1;

[0027] (3) Add 890 μL of NMP solution of ethylenediamine with a concentration of 10.56 mg / mL to the above solution, stir vigorously for half an hour, pour the mixture into the glass lining, and perform solvothermal at 150-180°C for 12 -24 hours.

[0028] The second step is to prepare a two-dimensional carbide crystal-based polyimide organic positive electrode material:

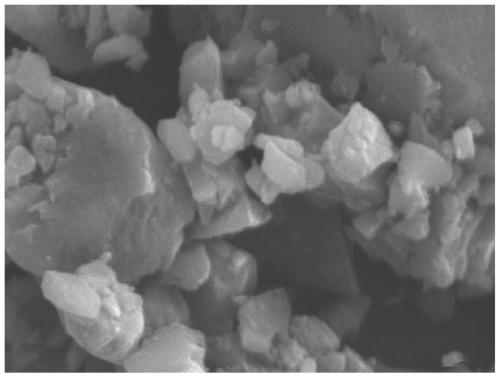

[0029] (1) The material obtained by solvothermal is put into a tube furnace for calcination in a nitrogen atmosphere, and kept at 400-500°C for 8-12 hours, and finally a two-dimension...

Embodiment 2

[0032] A method for preparing a two-dimensional carbide crystal-based polyimide organic positive electrode material, which solves the problem of composite construction of two-dimensional materials, includes the following steps:

[0033] (1) After MXene is centrifuged at high speed for many times to remove water, then dissolve MXene in NMP (methylpyrrolidone) solvent, and the concentration of MXeneN-methylpyrrolidone solution is 3 mg / ml;

[0034] (2) Naphthalenetetracarboxylic anhydride and ethylenediamine are added to the MXene solution, and the amount ratio of the added naphthalenetetracarboxylic anhydride and ethylenediamine is 1:1, and naphthalenetetracarboxylic anhydride is in the MXeneN-methylpyrrolidone solution The concentration is 12mg / ml, the temperature is controlled at 150°C, and after 20 hours of solvothermal in-situ polymerization;

[0035] (3) In a nitrogen atmosphere, control the high-temperature carbonization treatment temperature to 400° C. for 10 h, and obtai...

Embodiment 3

[0037] A method for preparing a two-dimensional carbide crystal-based polyimide organic positive electrode material, which solves the problem of composite construction of two-dimensional materials, includes the following steps:

[0038] (1) After MXene is centrifuged at high speed for many times to remove water, then dissolve MXene in NMP (methylpyrrolidone) solvent, and the concentration of MXeneN-methylpyrrolidone solution is 3 mg / ml;

[0039](2) Naphthalenetetracarboxylic anhydride and ethylenediamine are added to the MXene solution, and the amount ratio of the added naphthalenetetracarboxylic anhydride and ethylenediamine is 1:1.08, and naphthalenetetracarboxylic anhydride is in the MXeneN-methylpyrrolidone solution The concentration is 14mg / ml, the temperature is controlled at 180°C, and after 18 hours of solvothermal in-situ polymerization;

[0040] (3) In a nitrogen atmosphere, control the high-temperature carbonization treatment temperature to 400° C. for 9 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com