Photonic crystal composite pressure sensor and preparation method thereof, and optical detecting method

A pressure sensor and photonic crystal technology, applied in the field of sensing materials, can solve the problems of glass slides and other materials such as fragility, strong substrate attachment, and non-flexibility, achieving high sensitivity and flexibility, strong practical promotion value, and strong The effect of product suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

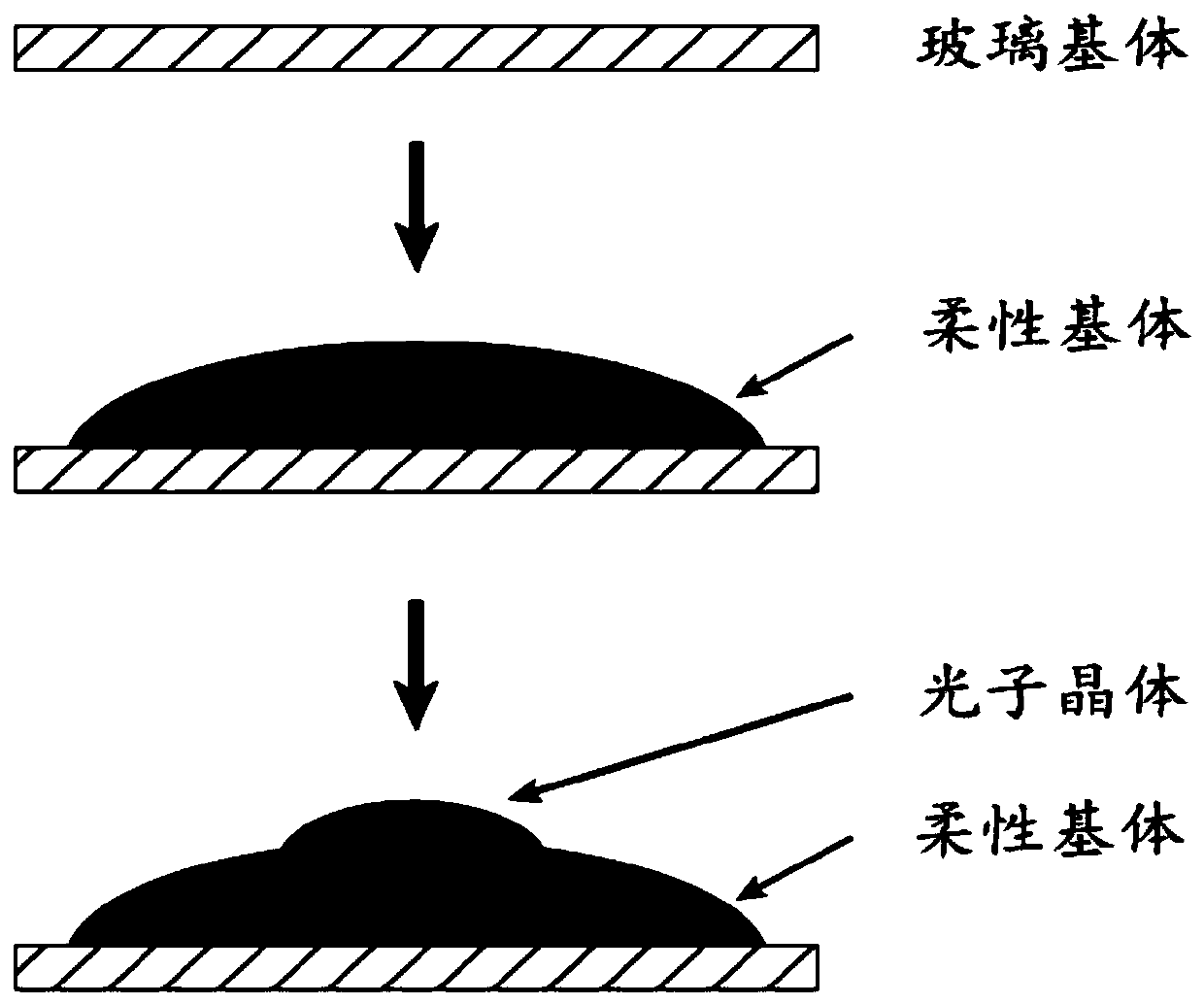

[0084] This embodiment provides a method for preparing an opal-type photonic crystal composite pressure sensor with a limited pitch arrangement, including the following steps:

[0085] S1. Preparation of photonic crystal precursor liquid:

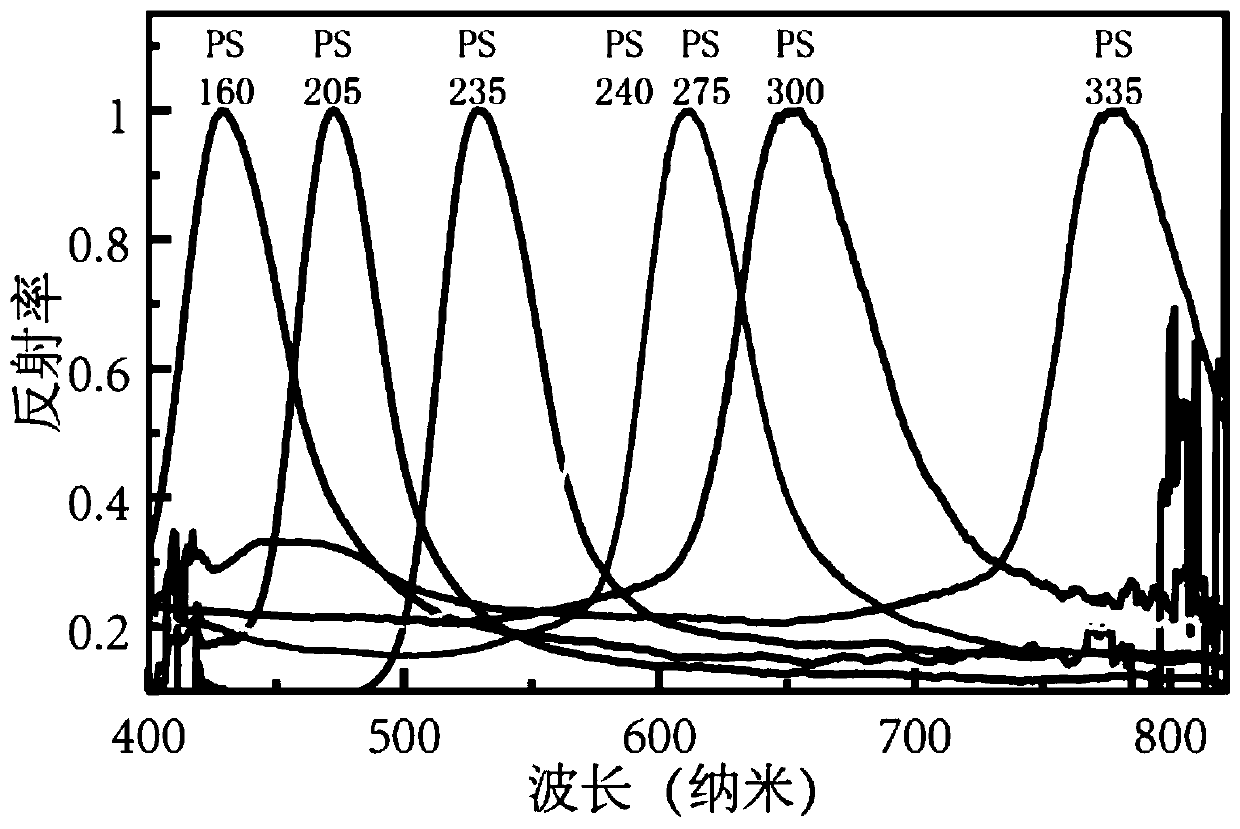

[0086] Monodisperse polystyrene microspheres with particle sizes of 160nm, 205nm, 235nm, 240nm, 275nm, 300nm, and 335nm were prepared by soap-free emulsion polymerization (with a particle size range of 100nm-1000nm). The solid content of the emulsion was about 10% (w / v), the steps are as follows:

[0087] Weigh 0.175g of ammonium persulfate into a beaker, add 20mL of deionized water to dissolve it. Measure 4.33mL, 3.58mL, 3.08mL, 3.00mL, 2.42mL, 2.00mL, 1.42mL of acrylic acid and 38.5mL of styrene, dissolve in 300mL of deionized water, stir in a 500mL four-neck flask at 250r / min, open Cooling water, nitrogen gas bubbling for 20min, and then heating in an oil bath to 70°C to stabilize, adding ammonium persulfate aqueous solution, turning o...

Embodiment 2

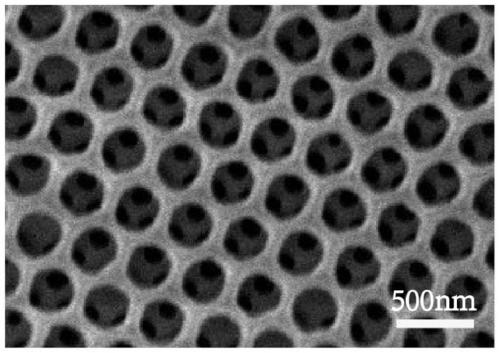

[0094] This embodiment provides a method for preparing an inverse opal-type photonic crystal composite pressure sensor with a defined porous spacing, including the following steps:

[0095] S1. Preparation of photonic crystal precursor liquid:

[0096] A monodisperse polystyrene microsphere emulsion with a particle size of 300 nm was prepared according to the method of Example 1, wherein the amount of acrylic acid added was 2.00 mL.

[0097] S2. Preparation of matrix precursor solution:

[0098] Preparation of silk protein solution: Wash the broken cocoons with 0.05% (w / v) sodium bicarbonate to remove sericin, then wash with deionized water, and dry naturally to obtain dry silk fibers. Dissolve the dried silk fibers in 9.2mol / L lithium bromide solution at 60°C, and precipitate lithium bromide in distilled water by dialysis to obtain a silk protein solution with a concentration of about 7% (w / v).

[0099] Preparation of keratin gel precursor: obtained according to the method ...

Embodiment 3

[0104] This embodiment provides a method for preparing a periodically arranged array photonic crystal composite pressure sensor, including the following steps:

[0105] S1. Preparation of matrix precursor solution:

[0106] According to Example 2, a matrix precursor solution with a concentration of 7% (w / v) was prepared.

[0107] S2. Preparation of photonic crystal composite pressure sensor:

[0108] Add 2wt% photosensitive small molecule o-nitrobenzaldehyde (2-NBA) to the matrix precursor solution, mix it evenly, and apply it on the substrate sheet, use the photolithography template of the matrix pattern as a mask, and irradiate it with ultraviolet light , causing rapid gelation, and then peeling off from the substrate, that is, a periodically arranged array photonic crystal composite pressure sensor is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com