Micro lens mask and preparation method thereof

A technology of microlens and reticle, applied in the field of microlens reticle and its preparation, can solve the problem of non-reusable microsphere array reticle, low efficiency of near-field probe scanning lithography, and inability to rapidly repeat preparation of micro-nano patterns and other issues, to achieve a wide range of size selection, improve lithography efficiency, and short cycle times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

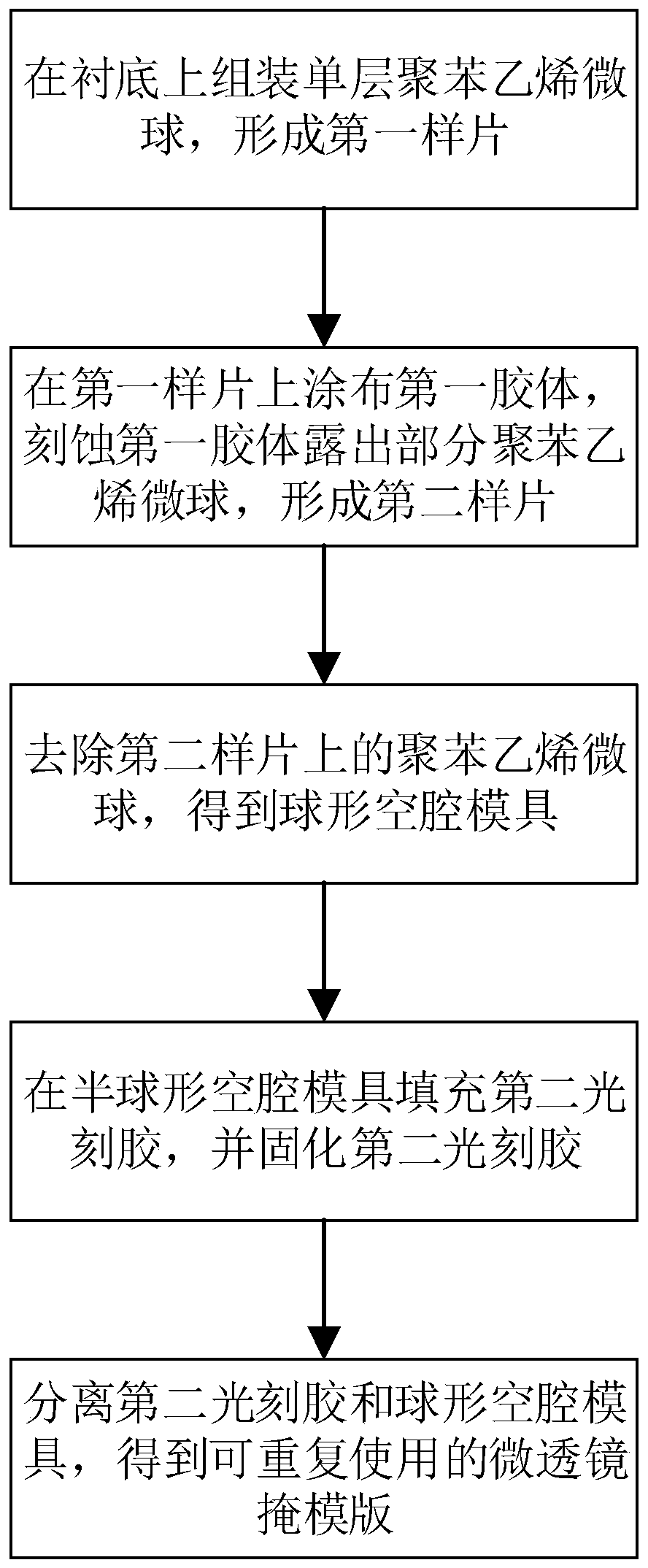

[0046] Such as figure 1 Shown, in embodiment 1, a kind of microlens reticle preparation method specifically comprises the following steps:

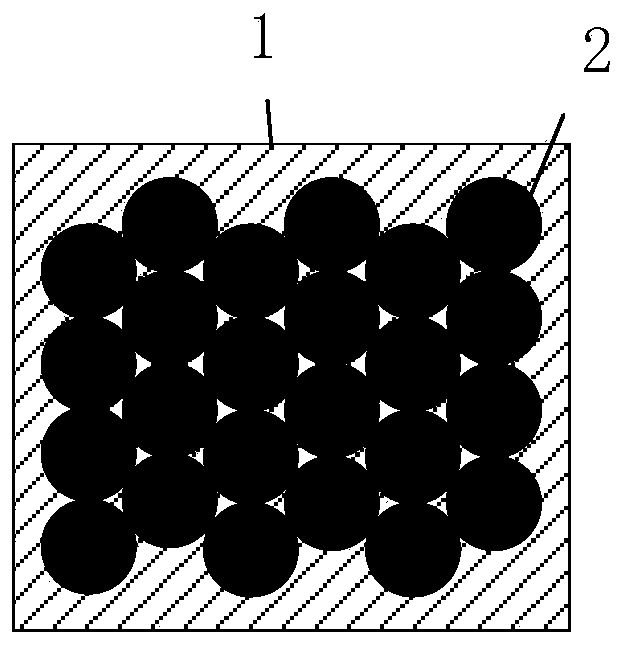

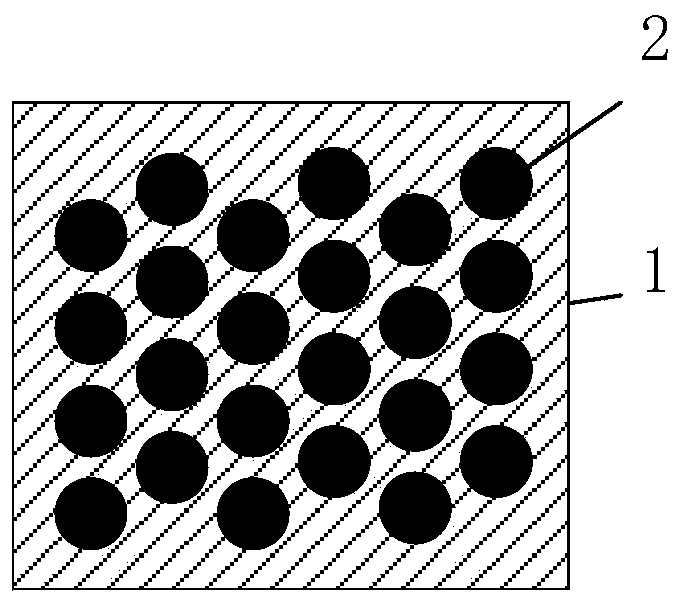

[0047] S01: Assemble a single-layer polystyrene microsphere 2 array on a substrate 1 to form a first sample; specifically, as figure 2As shown, prepare a clean and dry silicon substrate 1 substrate, use 5% w / v polystyrene microspheres with a diameter of 600nm 25ml, add 0.4ml of absolute ethanol, and assemble the closely arranged The polystyrene microsphere 2 array is assembled on the silicon substrate 1, and the size of the polystyrene microsphere 2 can be changed according to the size of the microlens reticle 8 to be prepared, and a single-layer polystyrene microsphere is assembled on the silicon substrate 1. Ethylene microsphere 2 array effects such as figure 2 shown. Further, the RIE etching method is used to etch the polystyrene microsphere 2 array to reduce the diameter of the polystyrene microsphere 2, so that the closely arran...

Embodiment 2

[0053] This embodiment has the same inventive concept as Embodiment 1. In Embodiment 2, a method for preparing a microlens reticle specifically includes the following steps:

[0054] S11: Assemble a single-layer polystyrene microsphere 2 array on a substrate 1 to form a first sample; specifically, prepare a clean and dry silicon substrate 1 substrate, using 5% w / v polystyrene microspheres with a diameter of 600 nm Add 0.4ml of absolute ethanol to 25ml of ethylene microspheres, and assemble the closely arranged array of polystyrene microspheres 2 on the silicon substrate 1 by the gas-liquid surface assembly method. It should be understood that the single assembly on the substrate 1 The method of layering the polystyrene microsphere 2 array includes but not limited to the air-liquid surface assembly method, and can also be other assembly methods, such as the spin coating method, and the size of the polystyrene microsphere 2 can be based on the microlens mask to be prepared 8 siz...

Embodiment 3

[0061] This embodiment provides a microlens reticle, specifically, as figure 2 As shown, the microlens reticle 8 includes a substrate 82 and several first microlenses 81 with spherical surfaces, and the first microlenses 81 and the substrate 82 are integrally formed.

[0062] Furthermore, both the first microlens 81 and the substrate 82 of the microlens reticle 8 are made of highly transparent polymers, such as highly transparent polymer PMMA photoresist, and inorganic transparent material silica. Wherein, since the microlens reticle 8 is prepared by the fluidity of a highly transparent polymer, the first microlens on the microlens reticle 8 can concentrate the incident light rays, so that when using the microlens mask When the template 8 is exposed, each light beam converges with higher energy and smaller spot size, thus obtaining a photolithographic effect with high resolution and good uniformity.

[0063] Furthermore, the present invention utilizes the fluidity of highly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com