Air electrode catalyst for metal air batteries and preparation method thereof and preparation method of air electrode for metal air batteries

A metal-air battery and air electrode technology, applied in the direction of fuel cell half-cells and primary battery half-cells, battery electrodes, circuits, etc., can solve the problems of poor performance and stability, achieve enhanced dispersion and avoid agglomeration , the effect of increasing the space interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

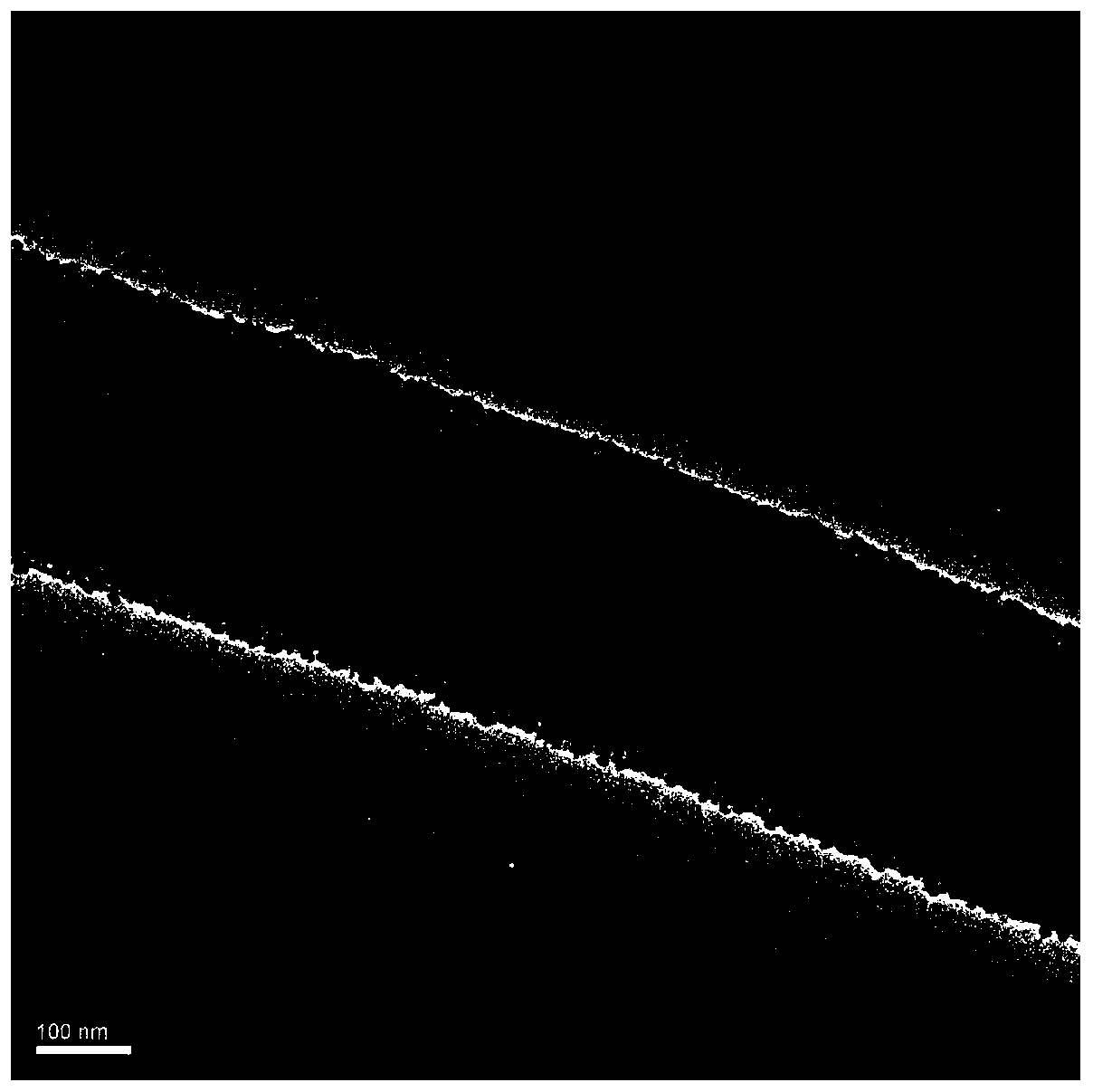

[0029] Embodiment 1: The preparation method of the air electrode catalyst of the metal-air battery in this embodiment is carried out according to the following steps

[0030] Step 1. According to the molecular formula NiCo 2 o x and NiCo 2 N y The molar ratio of each element in is weighed nickel nitrate, cobalt nitrate and N-methylthioacetamide, and then added to N,N-dimethylformamide to obtain a mixed solution a, which was stirred at a uniform speed at room temperature until completely dissolved , and then add polyvinylpyrrolidone to obtain the mixed solution b, magnetically stir at a uniform speed for 6 hours to obtain a clear solution, add N-methylthiourea to the mixed solution b, wherein, the moles of N-methylthiourea and nickel nitrate and cobalt nitrate The total molar ratio is 1:3, continue magnetic stirring at a constant speed for 3 hours to obtain a completely dissolved clarified electrospinning precursor solution;

[0031] Step 2. Add the electrospinning precurso...

Embodiment 2

[0037] Embodiment 2: The preparation method of the air electrode of the metal-air battery in this embodiment is carried out according to the following steps:

[0038] According to the ratio of ethanol: water: binder volume ratio of 4:1:1, take polyvinyl alcohol, ethanol and water, mix them, and ultrasonically uniform, according to the catalyst solution concentration of 8mg ml -1 Add the catalyst described in Implementation 1, and ultrasonically disperse the catalyst in the solution for 30 minutes; then evenly coat it on carbon paper and dry it for later use; cut a certain area of nickel foam as the current collector, and roll it to 5MP The pressure of the catalyst layer and the current collector are pressed together.

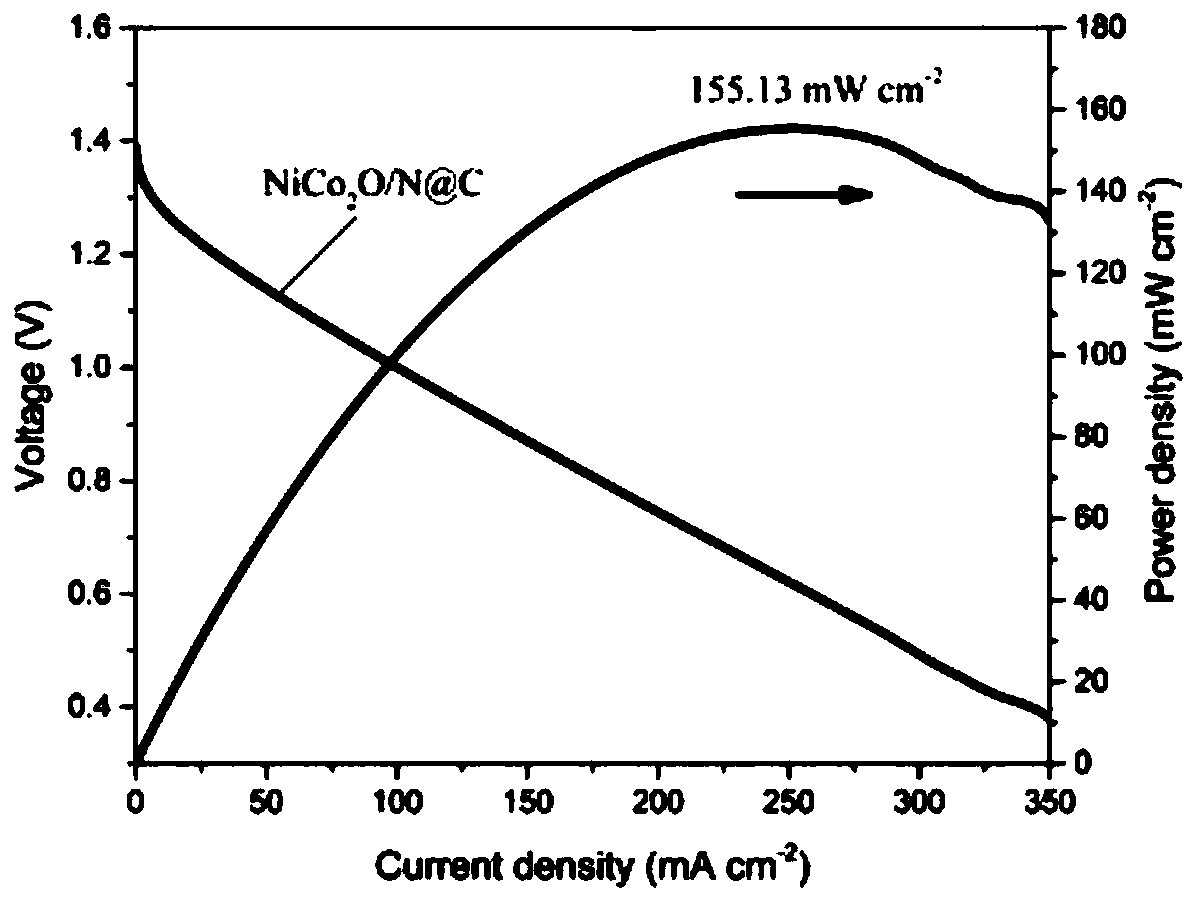

[0039] The air electrode of the metal-air battery of this embodiment is used in the zinc-air battery test system, and the electrolyte system of the zinc-air battery is 6M potassium hydroxide and 0.2M zinc acetate.

[0040] image 3 It is the discharge polari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com