Method for preparing elastic circuit board and elastic circuit board

A circuit board and elastic technology, applied in the manufacture of printed circuits, removal of conductive materials by chemical/electrolytic methods, printed circuits, etc., can solve problems such as poor tensile properties of elastic circuit boards, and achieve overcoming difficulties in welding and excellent ductility. , the effect of excellent mechanical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

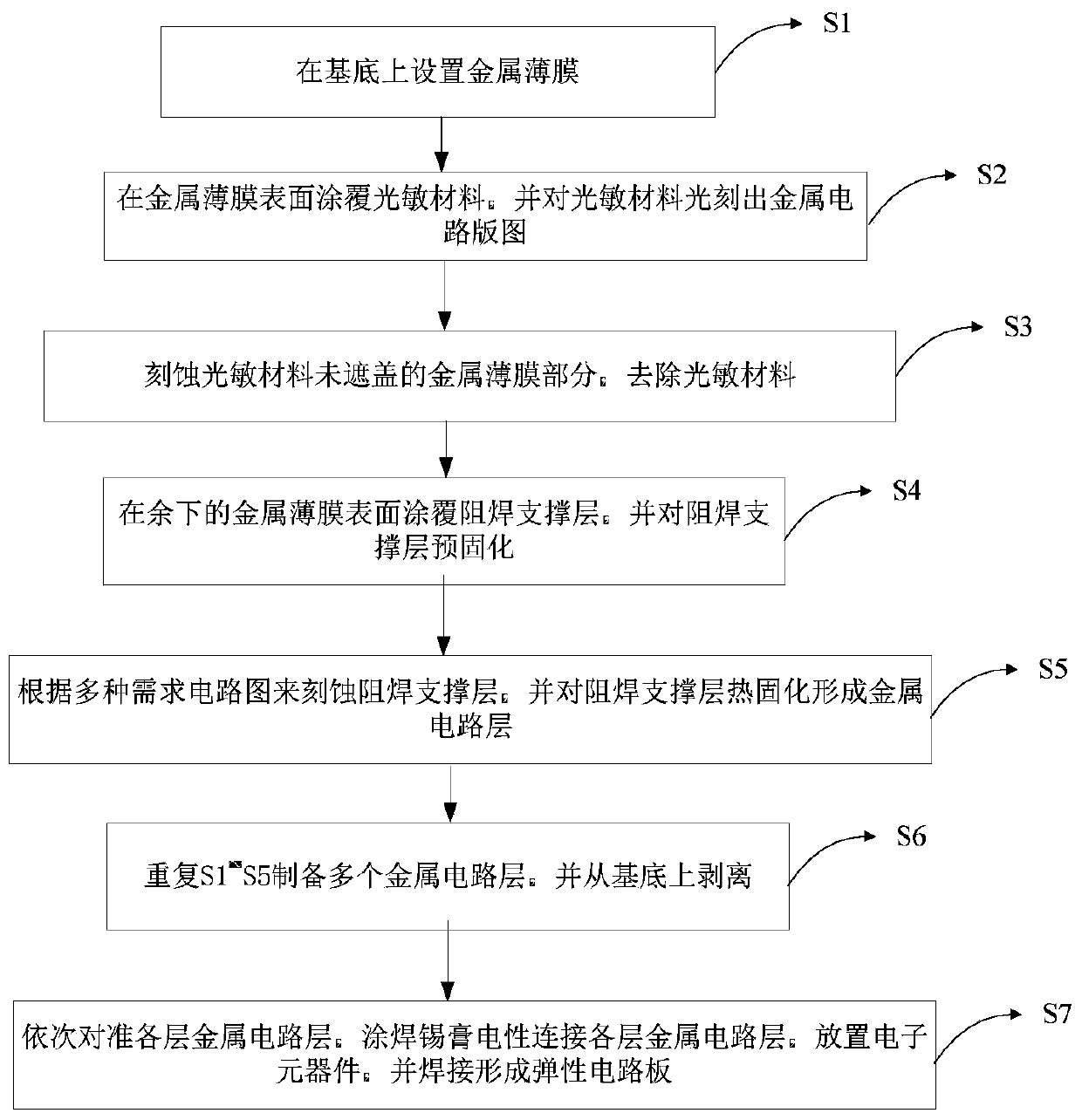

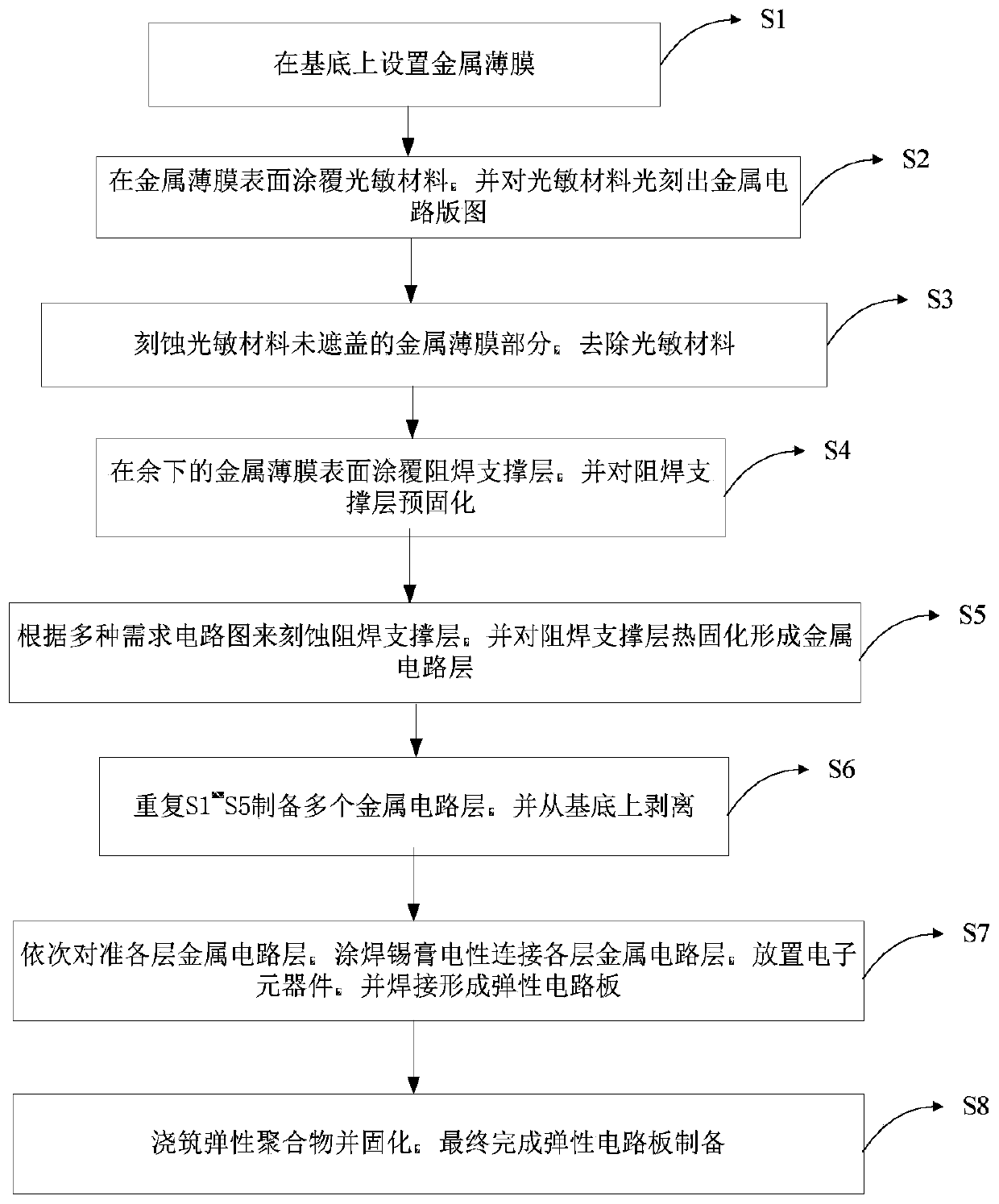

[0047] According to an embodiment of the present invention, a method for preparing a flexible circuit board is provided, see figure 1 , including the following preparation steps:

[0048] S1. setting a metal film 3 on the substrate 1;

[0049] S2. Coating a photosensitive material 4 on the surface of the metal thin film 3, and photoetching a metal circuit layout on the photosensitive material 4;

[0050] S3. Etching the part of the metal film 3 not covered by the photosensitive material 4 to remove the photosensitive material 4;

[0051] S4. Coating a solder resist support layer 5 on the surface of the remaining metal film 3, and pre-curing the solder resist support layer 5; the solder resist support layer 5 needs to meet the required curvature, and can be patterned and insulated at the same time.

[0052] S5. Etching the solder resist support layer 5 according to various required circuit diagrams, and thermally curing the solder resist support layer 5 to form a metal circui...

Embodiment 1

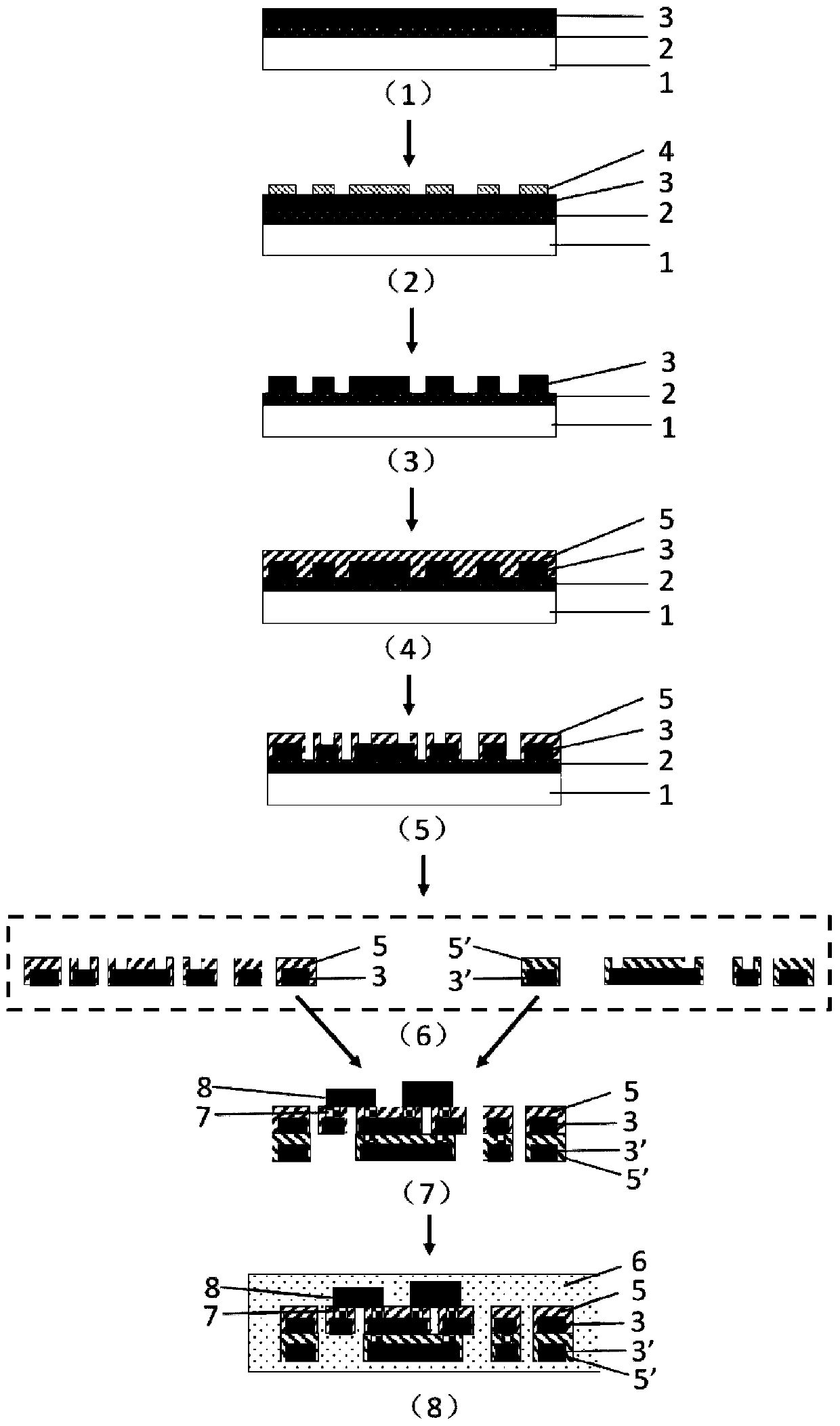

[0059] This embodiment relates to a method for preparing an elastic circuit board. The process flow for preparing the elastic circuit board is as follows: image 3 shown. Utilize the schematic diagram of the cross-section of the elastic circuit board processed by the present invention as Figure 4 As shown, it includes two layers of metal circuit layers, that is, two layers of metal films 3 and 3' and two layers of solder resist support layers 5 and 5', elastic polymer 6, solder paste 7 and a number of electronic components 8; in view of copper Metal has the advantages of low cost, superior electrical properties (low resistivity), easy etching and molding, etc. The metal film 3 and 3' material of this embodiment is copper; considering the copper metal layer thickness of 1 ounce of copper printed circuit board About 35 microns, in order to obtain similar current carrying capacity, the thickness of the metal film 3 and 3' in this embodiment is 40 microns, the minimum line width...

Embodiment 2

[0076] The preparation method of a flexible circuit board involved in this embodiment is the same as that of Embodiment 1, except that the metal film 3 is made of a low-cost aluminum film with a thickness of 10 microns; the minimum line width of the aluminum circuit is 10 microns; The support layer 5 is non-photosensitive polyimide, with a thickness of 15 microns and a minimum line width of 15 microns; the non-photosensitive polyimide solder resist support layer 5 is patterned by dry etching; the elastic polymer 6 It is silicone rubber with good tensile properties and biocompatibility, with a thickness of 1.5mm and 4 metal circuit layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com