Coating material, coated controlled-release pesticide fertilizer, preparation method and application thereof

A coating material, fertilizer technology, applied in the application, layered/coated fertilizer, nitrogen fertilizer and other directions, can solve the problems of solvent volatilization, pollution of the environment, etc., achieve complete coating, good controlled release performance, and increase added value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

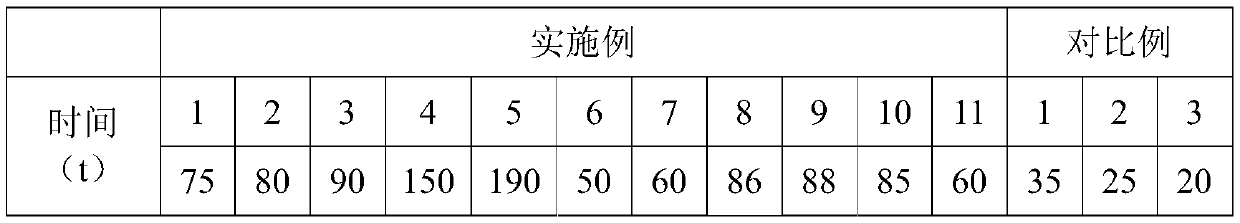

Embodiment 1

[0073] This example provides an insecticidal single-coated controlled-release medicinal fertilizer, the composition and preparation method of which are as follows.

[0074] Composition of medicinal fertilizer: insecticide: 3.6 parts (each part is calculated as 1kg, the same below) pure, urea: 20 parts, potassium sulfate: 20 parts, magnesium carbonate: 10 parts, 100 mesh bentonite: 41.4 parts, binder: 1wt% sulfuric acid and 1wt% xanthan gum solution, 5 parts.

[0075] The preparation process is as follows.

[0076] (1) Measure and mix urea, potassium sulfate and magnesium carbonate, and then pulverize them on a fertilizer special pulverizer to make them into powder.

[0077](2) Add the pulverized fertilizer, monosultap and 100-mesh swelling into the disc granulator, mix evenly while adding, and then add the binder to granulate. After granulation, dry at 50-60°C, pass through double-layer sieves, make the particle size between 1-6mm, and the strength of the particles is above ...

Embodiment 2

[0084] This embodiment provides a monosultap-coated controlled-release medicinal fertilizer, its composition and preparation method are as follows: 97 parts of 9-0-10-3.6 monosultap, 1 part of coating material A, and 2 parts of coating material B.

[0085] The composition and preparation method of coating material A are as follows: 10 parts of coating material A are composed of 8 parts of vegetable oil polyol castor oil polyol, 1.6 parts of film-forming auxiliary agent peanut oil, 0.3 part of organometallic compound catalyst stannous octoate, and 0.1 part of porogen Composed of magnesium carbonate. Mix vegetable oil polyols, film-forming aids, and organometallic compound catalysts, heat at 50°C, and react for 25 minutes under stirring to obtain vegetable oil coating materials; mix vegetable oil coating materials and porogens, and heat at 50°C Blending and polymerization were carried out to obtain 10 parts of coating material A.

[0086] Coating material B: Trimethylhexamethyl...

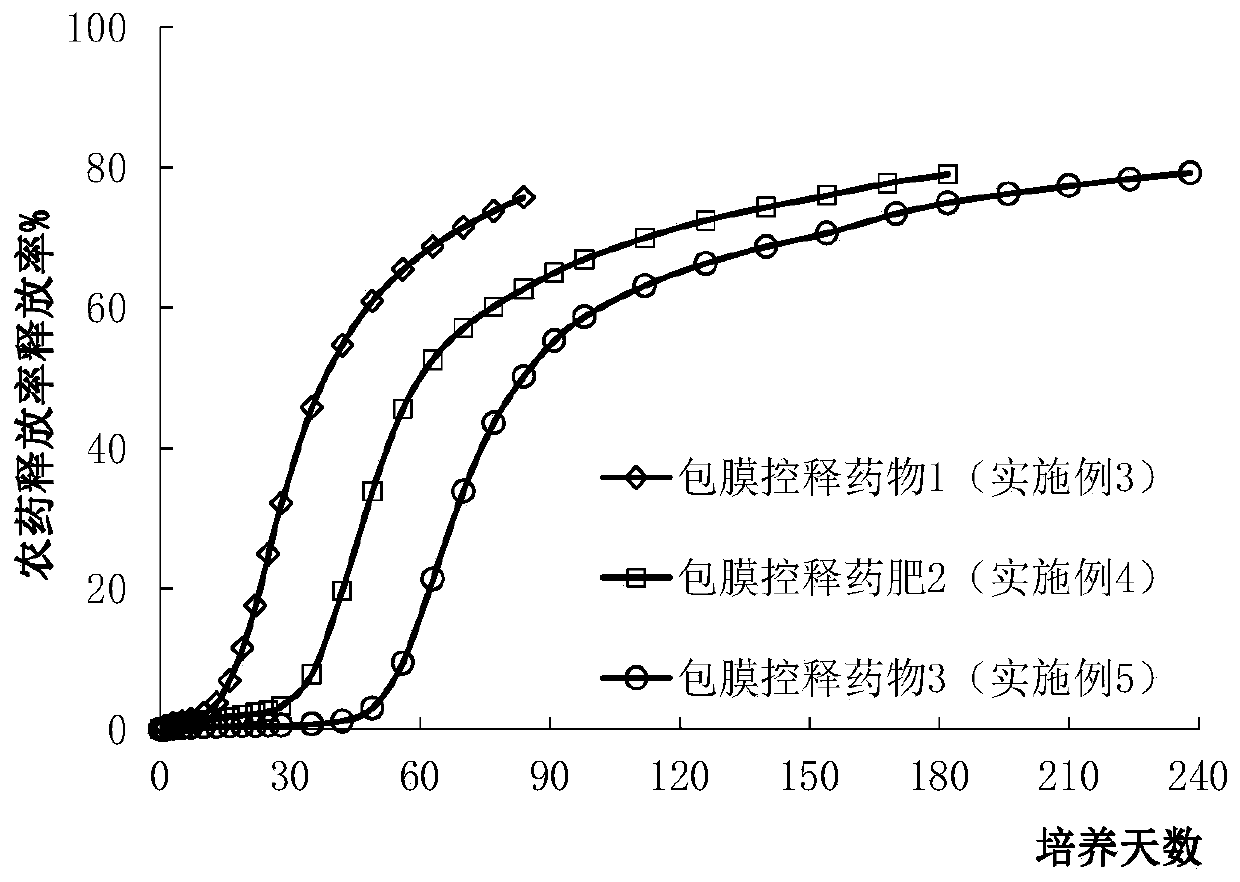

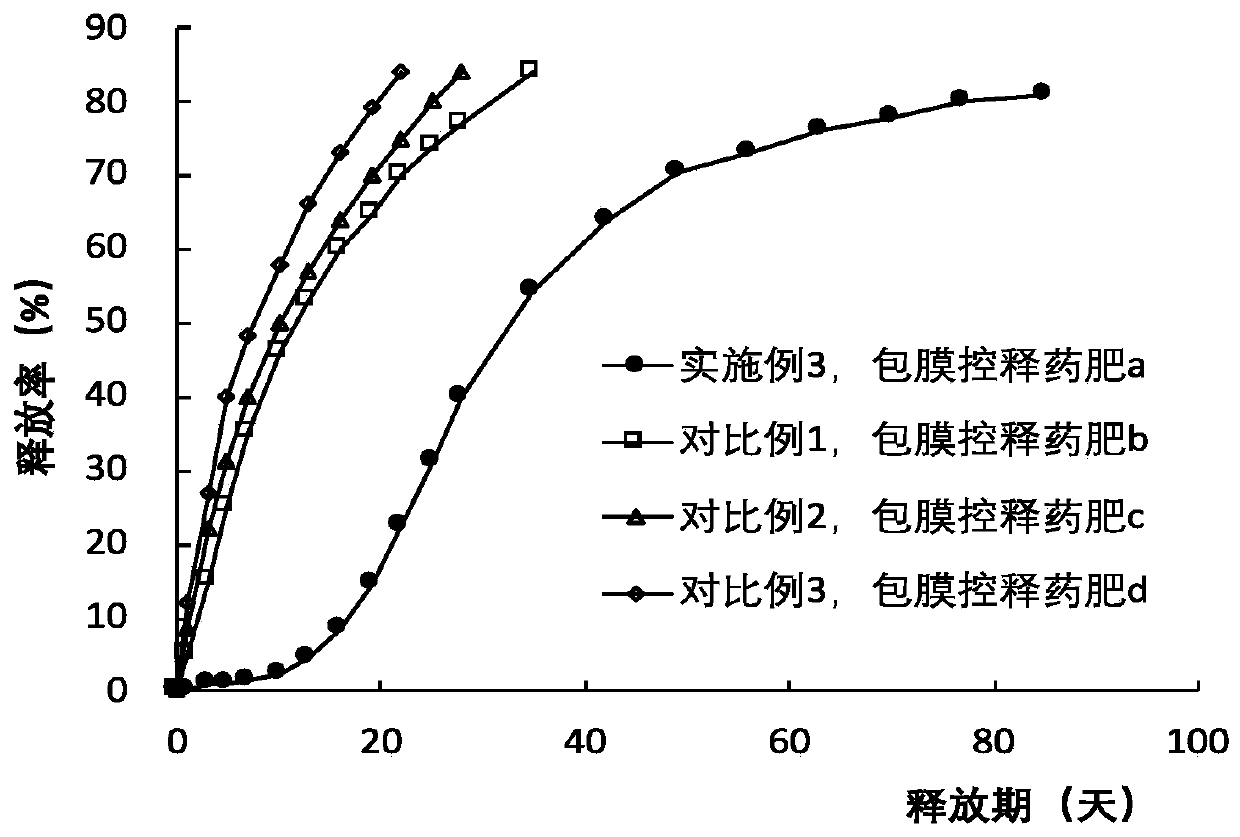

Embodiment 3

[0089] This embodiment provides a monosultap-coated controlled-release medicinal fertilizer, whose composition and preparation method are as follows: 97 parts of 9-0-10-3.6 monosultap, 1.67 parts of coating material A, and 1.33 parts of coating material B.

[0090] The composition and preparation method of coating material A are as follows: 10 parts of coating material A are composed of 6.4 parts of vegetable oil polyol castor oil polyol, 1.6 parts of soybean oil polyol, 1.6 parts of film-forming auxiliary agent peanut oil, 0.3 part of organometallic compound catalyst octanoic acid Composed of stannous, 0.1 part porogen magnesium carbonate. Mix vegetable oil polyols, film-forming aids, and organometallic compound catalysts, heat at 50°C, and react for 25 minutes under stirring to obtain vegetable oil coating materials; mix vegetable oil coating materials and porogens, and heat at 50°C Blending and polymerization were carried out to obtain 10 parts of coating material A.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com