Quartz glass and ultraviolet emitting element member using same

A technology of quartz glass and straight lines, applied in the field of components for ultraviolet light-emitting elements, can solve problems such as low productivity, achieve the effects of suppressing deterioration and good laser processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

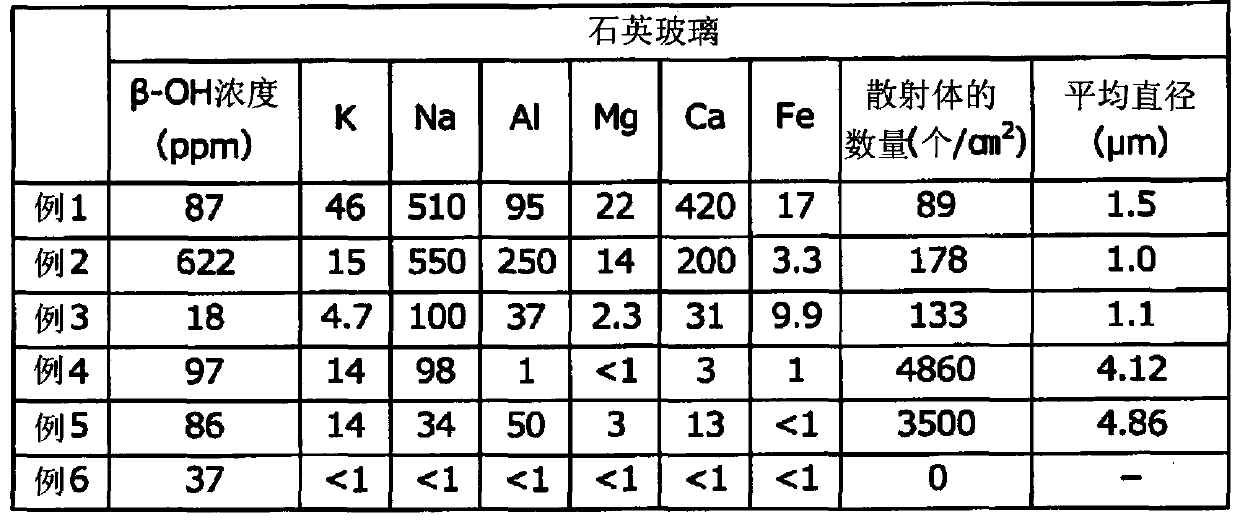

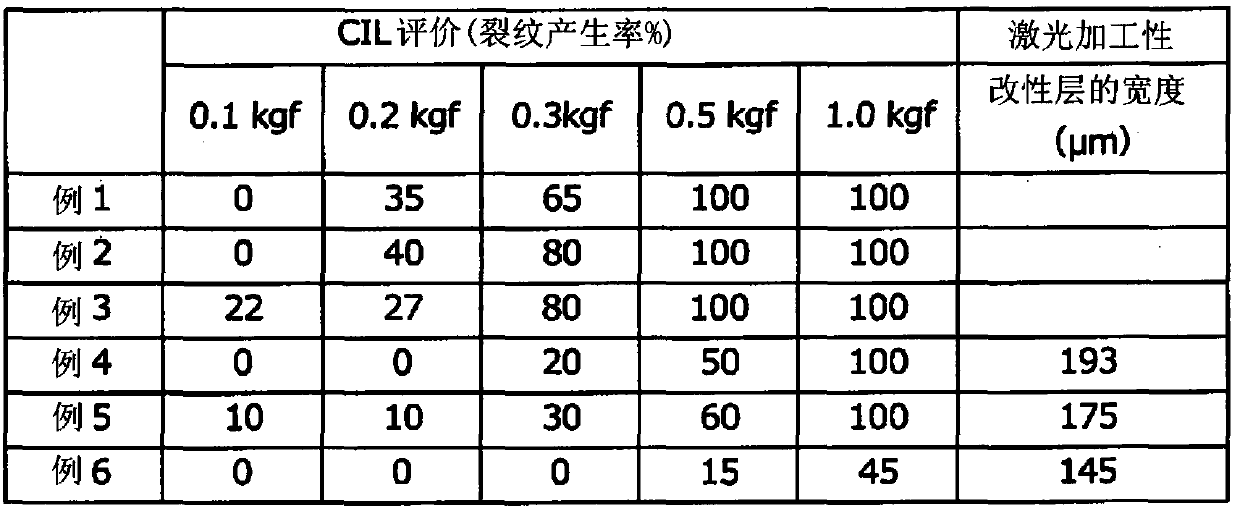

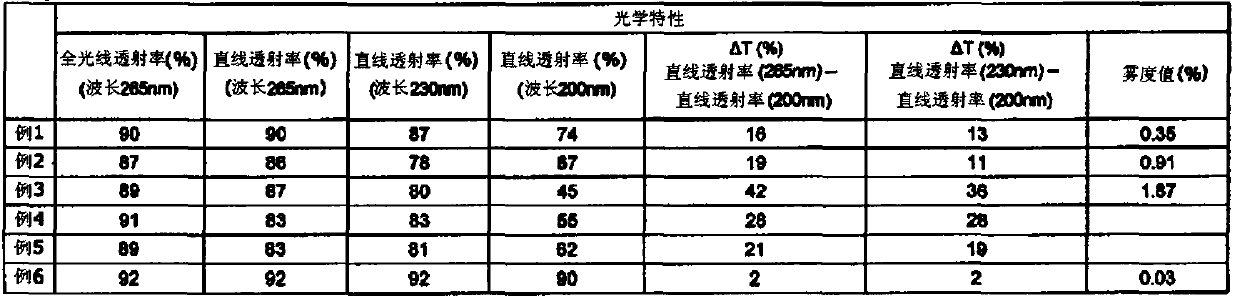

example 1

[0113] The above steps of Step 1 to Step 8 are carried out to obtain quartz glass.

[0114] In step 1, the purity of 99.9% or more, the average particle size of 20nm, and the specific surface area of 90m 2 33.9 parts by mass of silicon dioxide powder / g as a raw material was dispersed in 66.1 parts by mass of water whose pH was adjusted to 13 using a pH adjuster as a solvent to prepare a dispersion liquid.

[0115] In step 2, 88.2 parts by mass of the above-mentioned dispersion liquid, 10.0 parts by mass of the water-soluble epoxy resin, and 1.8 parts by mass of the aliphatic amine curing agent were mixed and defoamed by a rotary mixer equipped with a vacuum pump to prepare a mixed solution.

[0116] In step 3, the above-mentioned liquid mixture was filled in a mold made of polyethylene with a diameter of 30 mm×10 mmt.

[0117] In step 4, the liquid mixture filled in the mold is allowed to stand at room temperature to be solidified.

[0118] After the molded body is taken o...

example 2

[0140] In step 7, the molded body degreased in step 6 was subjected to atmospheric firing at 1125° C. instead of vacuum firing. Except for the step 7, the same procedure as in Example 1 was carried out.

example 3

[0142] In step 1, the purity of 99.9% or more, the average particle size of 100nm, and the specific surface area of 55 to 65m 2 A dispersion was prepared by dispersing 62.9 parts by mass of silica powder / g as a raw material and 37.1 parts by mass of water whose pH was adjusted to 13 with a pH adjuster as a solvent.

[0143] In step 2, 94.1 parts by mass of the dispersion liquid, 5.0 parts by mass of the water-soluble epoxy resin, and 0.9 parts by mass of the aliphatic amine curing agent were mixed and defoamed using an autorotation-revolution mixer equipped with a vacuum pump to prepare a mixed solution.

[0144] In the following steps, the same steps as in Example 1 were carried out to obtain quartz glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com