Nano silica microsphere with surface topological structure and preparation method of nano silica microsphere

A technology of nano-silica and topological structure, applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve problems such as difficult batch preparation and complex synthesis process, and achieve the effect of reducing pollutant emissions and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

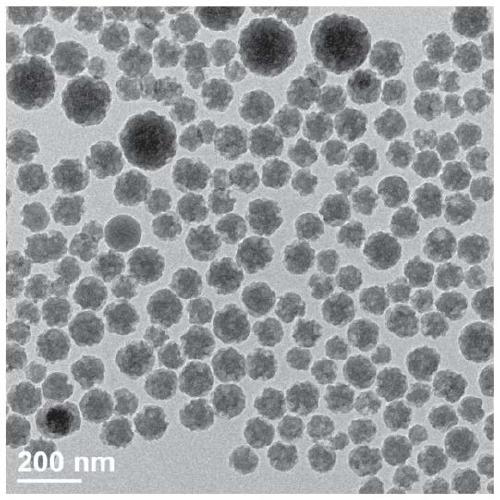

[0059] Example 1: Inject 50ml of water and 1ml TEOS into a 250mL Erlenmeyer flask at a room temperature of 20°C under stirring, and stir (300rmp at a rotational speed) for 2 hours; add 40ml of ethanol to the Erlenmeyer flask, and stir at a room temperature of 20°C (rotational speed 300rmp) 2 hours, the concentration of TEOS is 0.05M; Add mass fraction 28% ammonia solution in conical flask, make the concentration of ammonia reach 0.44mol / L, react 2h under the condition of stirring (rotational speed 200rmp), add to it A certain volume of 3.3% ammonia solution was added (ratio of the volume of added ammonia water to the volume of the original sol, 17:5), and reacted for 12 hours to obtain silica sol. Silica sol was centrifuged at room temperature at 20°C (rotating speed 15000rmp, time 30min), and washed with ethanol 3 times to obtain silica microspheres with an average particle diameter of 103nm and a uniform surface topological structure (see figure 1 ).

Embodiment 2

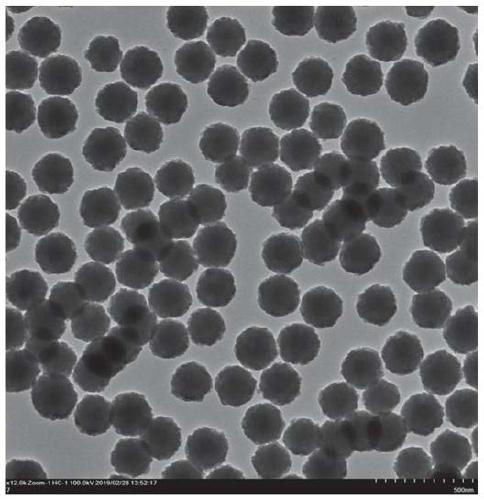

[0060] Example 2: Inject 30ml of water and 3ml TEOS into a 250mL Erlenmeyer flask at a room temperature of 20°C under stirring, and stir (300rmp at a rotational speed) for 2 hours; add 40ml of ethanol to the Erlenmeyer flask, and stir at a room temperature of 20°C (rotational speed 300rmp) 2 hours, the concentration of TEOS is 0.19M; Add mass fraction 28% ammoniacal solution to conical flask, make the concentration of ammonia reach 1.48mol / L, react 2h under the condition of stirring (rotational speed 250rmp), add to it A certain volume of 2.8% ammonia solution was added (ratio of the volume of added ammonia water to the volume of the original sol, 50:11), and reacted for 11 hours to obtain silica sol. Under the condition of room temperature 20°C, the silica sol is centrifuged (rotating speed 5000rmp, time 10min), and the silica sol is washed 3 times with ethanol to obtain silica microspheres with an average particle diameter of 250nm and uniform size (see figure 2 ).

Embodiment 3

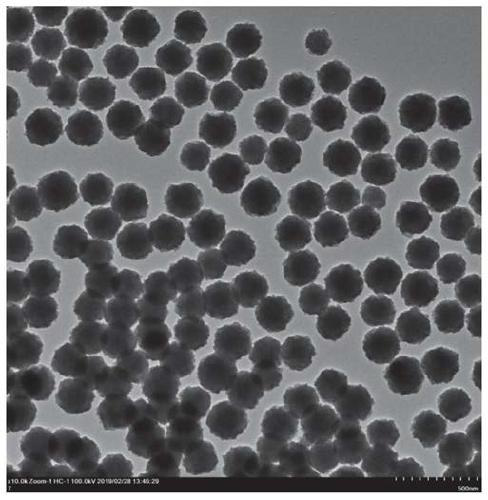

[0061] Example 3: Inject 25ml of water and 5ml TEOS into a 250mL Erlenmeyer flask at a room temperature of 20°C under stirring, and stir (rotating at 300rmp) for 2 hours; add 35ml of ethanol to the Erlenmeyer flask, and stir at a room temperature of 20°C (rotating speed 300rmp) 2 hours, the concentration of TEOS is 0.36M; Add mass fraction 28% ammonia solution in conical flask, make the concentration of ammonia reach 1.48mol / L, after stirring (rotating speed 300rmp) condition 2h, add to A certain volume of 2.8% ammonia solution was added therein (the ratio of the volume of added ammonia water to the volume of the original sol was 50:11) and reacted for 10 hours to obtain a silica sol. Silica sol was centrifuged at room temperature at 20°C (rotating speed 4000rmp, time 20min), washed with ethanol 3 times, and silica microspheres with an average particle diameter of 225nm and uniform size could be obtained (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com