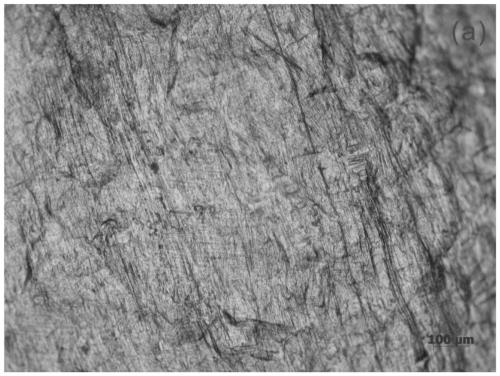

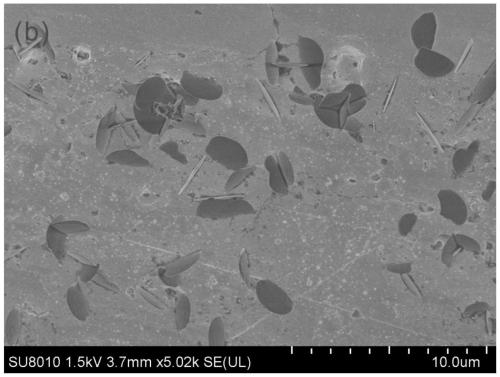

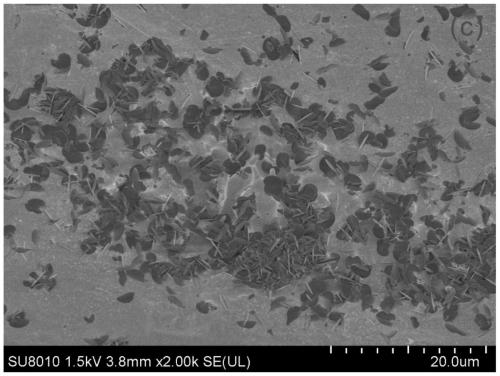

A kind of high (001) surface flaky zirconia and its preparation method

A technology of zirconia and flakes, applied in zirconia and other directions, can solve the problems of zirconia morphology limitations, etc., and achieve the effect of intact crystal plane, low reaction temperature and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (1) 0.92g of fluozirconic acid solution (45% concentration of H 2 ZrF 6 Solution, Shanghai McLean Company, the same below) was dissolved in 100ml deionized water, and was diluted to obtain a 0.02mol / L solution to be reacted, and the prepared reaction solution was packed into a 200ml hydrothermal reactor, which was sealed at high temperature High-pressure reaction kettle, high-temperature and high-pressure reaction kettle is connected with high-precision ultra-high pressure pressure gauge, ventilation pipe, air inlet, and gas outlet stop valve. High-temperature and high-pressure reaction kettle has a metal shell, and a polytetrafluoroethylene internal Lining, place a flat gold sheet at the bottom of the reactor, tighten the reactor, close the gas outlet shut-off valve, open the air inlet shut-off valve, inject argon into the kettle through the ventilation pipe to a pressure of 80MPa, close the air inlet to stop The valve stops gas injection, and the reactor is heated th...

Embodiment 2

[0071] (1) Dissolve 0.46g of 45% concentration of fluozirconic acid solution in 100ml of deionized water, dilute to obtain a 0.01mol / L solution to be reacted, and put the prepared reaction solution into a 200ml hydrothermal reaction kettle, hydrothermal reaction kettle In order to seal the high-temperature and high-pressure reactor, the high-temperature and high-pressure reactor is connected with a high-precision ultra-high pressure pressure gauge, a ventilation pipe, an air inlet, and an outlet valve. Lining, place a flat gold sheet at the bottom of the reactor, tighten the reactor, close the gas outlet shut-off valve, open the air inlet shut-off valve, inject argon gas into the kettle through the ventilation pipe to a pressure of 50MPa, close the air inlet to stop The valve stops gas injection, and the reactor is heated through the heating furnace, and the reaction temperature is set to 250°C;

[0072] (2) After the temperature rises to 250°C, open the cut-off valve of the a...

Embodiment 3

[0075] (1) Dissolve 0.92g of 45% concentration of fluozirconic acid solution in 100ml deionized water, dilute to obtain a 0.02mol / L solution to be reacted, and put the prepared reaction solution into a 200ml hydrothermal reaction kettle, hydrothermal reaction kettle In order to seal the high-temperature and high-pressure reactor, the high-temperature and high-pressure reactor is connected with a high-precision ultra-high pressure pressure gauge, a ventilation pipe, an air inlet, and an outlet valve. Lining, after tightening the reactor, close the shut-off valve of the gas outlet, open the shut-off valve of the inlet, inject argon into the kettle through the ventilation pipe to a pressure of 80MPa, close the shut-off valve of the inlet to stop the gas injection, and heat the reactor through the heating furnace. Heating is carried out, and the reaction temperature is set to 250°C;

[0076] (2) After the temperature rises to 250°C, open the cut-off valve of the air inlet in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com