Method for preparing Anilofos by recycled ammonium thiophosphate salt from phosphorus-containing wastewater

A technology of phosphorothioate ammonium salt and saponin, which is applied in the field of chemical pesticide preparation to achieve the effects of cheap and easy-to-obtain raw materials, convenient operation, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

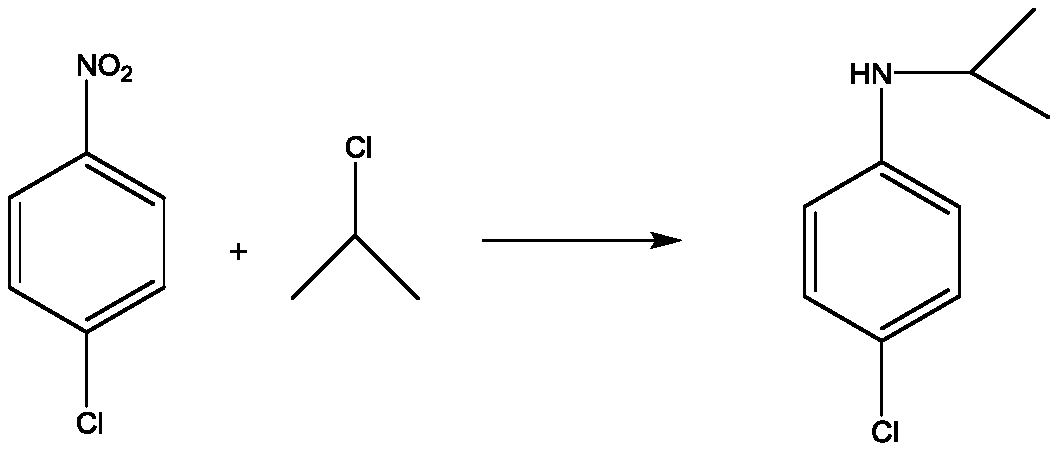

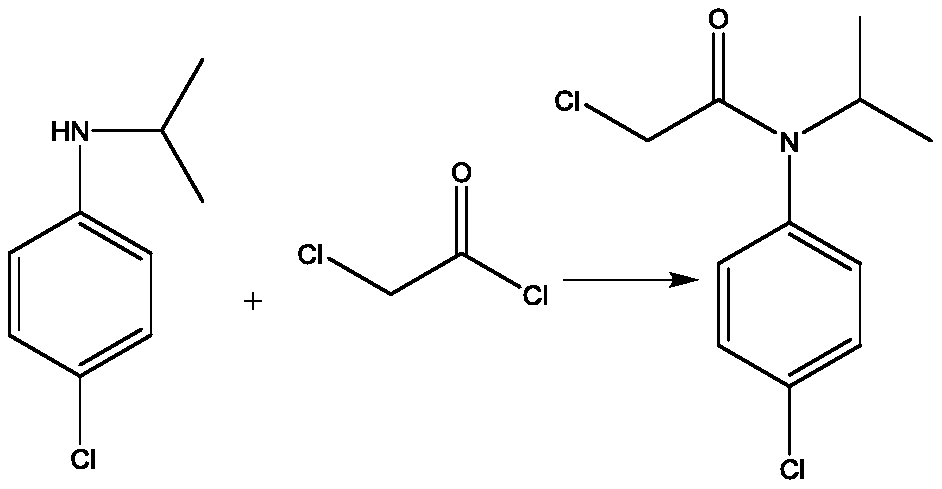

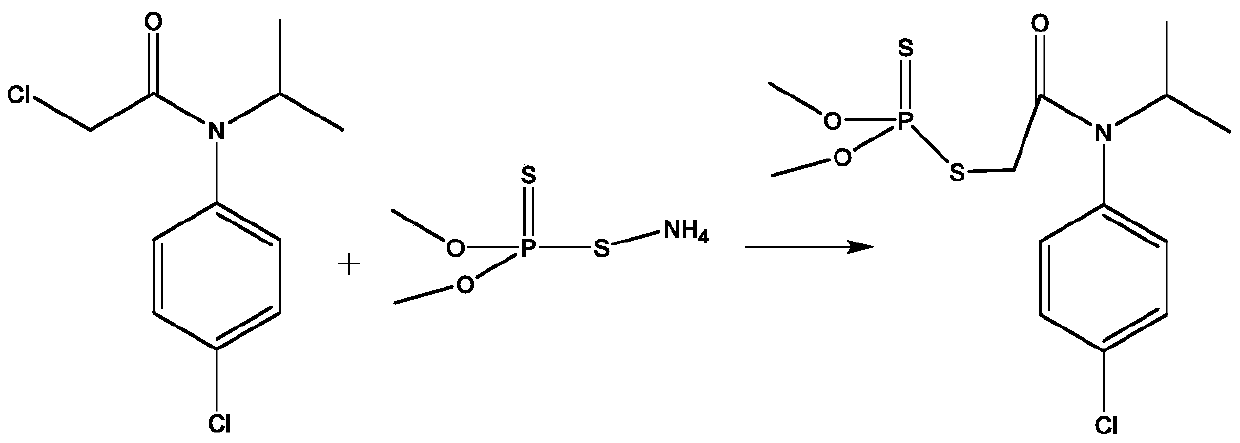

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing saponin by reclaiming phosphorothioate ammonium salt from phosphorus-containing wastewater, comprising the following steps:

[0029] (1) after the malathion synthetic reaction finishes, add the pure water of malathion process oil weight 10% in the malathion process oil, slowly add massfraction 25% ammoniacal liquor, temperature is controlled below 20 ℃, Ammonia water was added dropwise until the pH of the reaction system was 9, then the dropwise addition was completed, and after standing for 80 minutes, an aqueous methyl sulfide ammonium salt solution was obtained, which was filtered, extracted with toluene, dehydrated by a low-temperature evaporation system, and centrifuged in a centrifuge. , obtain the methyl sulfide ammonium salt solid, wherein the quality of the methyl sulfide ammonium salt solid obtained is as shown in Table 1:

[0030] project purity,% Moisture, % Methyl sulfide ammonium salt solid 96 1

[0031] (2) ...

Embodiment 2

[0036] A method for preparing saponin by reclaiming phosphorothioate ammonium salt from phosphorus-containing wastewater, comprising the following steps:

[0037] (1) after the synthetic reaction of malathion finishes, add the pure water of malathion process oil weight 10% in the malathion process oil, slowly add massfraction 25% ammoniacal liquor, temperature is controlled below 20 ℃, Ammonia water is added dropwise until the pH of the reaction system is 9, the dropwise addition is completed, and after standing for 100 minutes to separate layers, an aqueous solution of methyl sulfide ammonium salt is obtained, which is filtered, extracted with toluene, dehydrated by a low-temperature evaporation system, and centrifuged in a centrifuge. , obtain the methyl sulfide ammonium salt solid, wherein the quality of the methyl sulfide ammonium salt solid obtained is as shown in Table 2:

[0038] project purity,% Moisture, % Methyl sulfide ammonium salt solid 97 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com