Treatment method for surface modification of high thermal conductivity carbon fiber

A treatment method and surface modification technology, which is applied in fiber treatment, carbon fiber, textiles and papermaking, etc., can solve the problems of increased surface graphitization order, poor wettability, and increased difficulty, so as to improve the treatment effect, The effect of increasing wettability and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

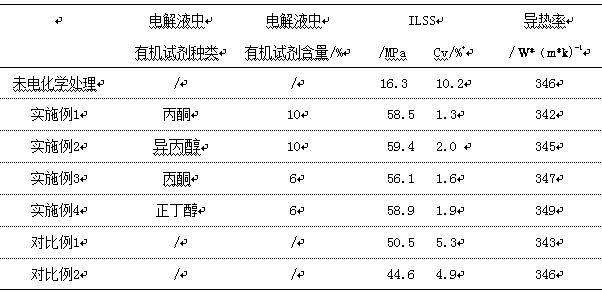

Embodiment 1

[0015] The 1.5K mesophase pitch-based carbon fiber obtained by heat treatment at 2800°C was electrochemically treated by constant current anodic oxidation technology. The electrolyte configuration method was as follows: 30g ammonium bicarbonate, 10g ammonium acetate and 10g ammonium dihydrogen phosphate were dissolved in 400g deionized water, Then add 50g of acetone and mix well. With carbon fiber as the anode and stainless steel plate as the cathode, the carbon fiber is subjected to constant current oxidation treatment at 50°C, and the current density is 2mA / cm 2 . The surface-treated carbon fiber was tested for thermal conductivity and ILSS respectively. The ILSS test sample was obtained by compounding the surface-treated carbon fiber with bisphenol A epoxy resin 6101. The volume ratio of carbon fiber to resin was 6:4, and the curing agent was Triethylenetetramine, curing temperature 80°C, curing time 2 hours. The test results are shown in Table 1.

Embodiment 2

[0017] Replace the acetone in embodiment 1 with 50g isopropanol, and others are the same as embodiment 1. The test results are shown in Table 1.

Embodiment 3

[0019] The electrolytic solution preparation method is as follows: 30g of ammonium bicarbonate, 10g of ammonium acetate and 10g of ammonium dihydrogen phosphate were dissolved in 420g of deionized water, and then 30g of acetone was added and mixed evenly. Others were the same as in Example 1. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com