Self-repairing modified silicone rubber and preparation method thereof

A modified silicon, self-healing technology, applied in the field of polymer materials, can solve the problems of volatile matter release and energy consumption environment, single self-healing mechanism, unable to obtain self-healing effect materials and other problems, achieve excellent self-healing function, Avoiding environmental problems and enhancing resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of self-healing modified silicone rubber, specifically comprising the steps of:

[0046] step one:

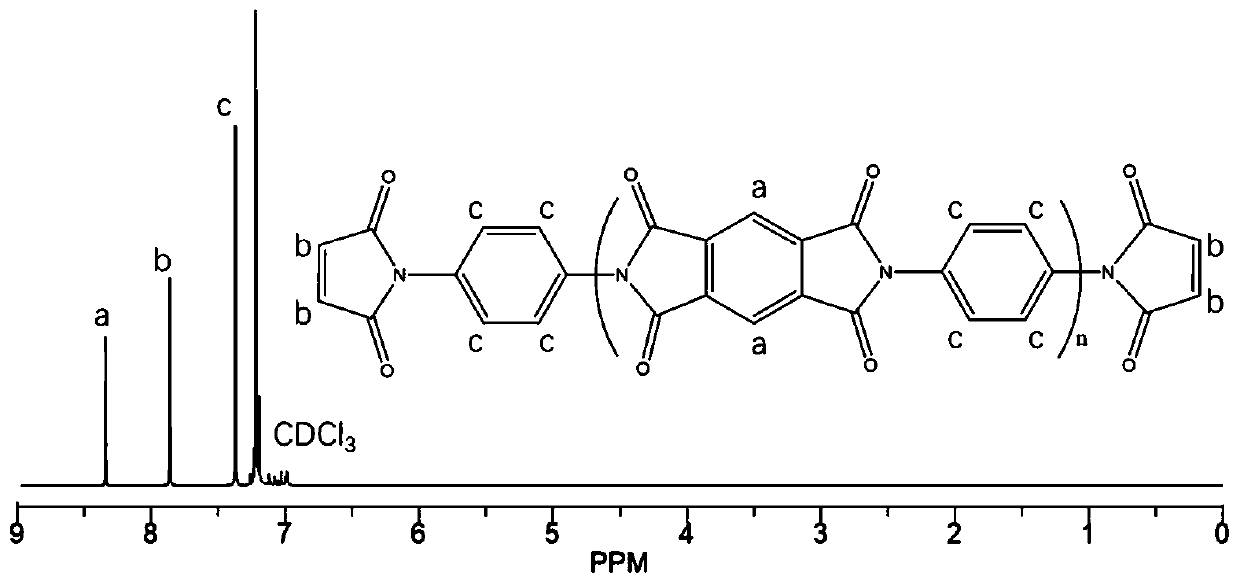

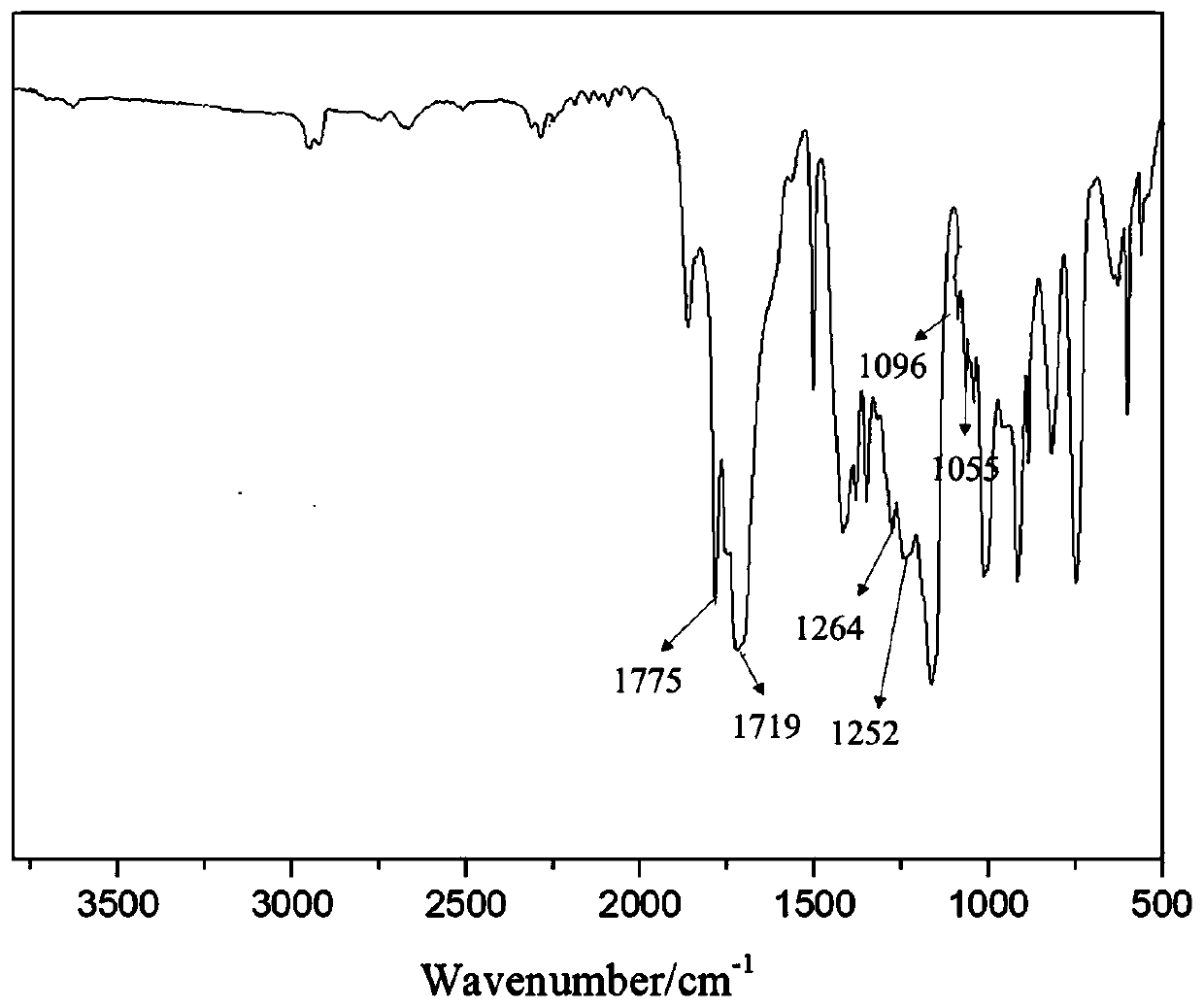

[0047] Add 1.0 parts of phenylenediamine and 0.5 parts of pyromellitic anhydride to dimethylacetamide, stir at room temperature for 5 hours, add 0.1 parts of maleic anhydride, continue the reaction for 3 hours, add 1.5 parts of triethylamine and 1.5 parts of acetic anhydride parts, the temperature was raised to 60°C, and the reaction was carried out for 8h. The reaction solution was poured into petroleum ether, a large amount of solid precipitation occurred, filtered, the obtained solid was washed 3 times with 5wt% aqueous sodium bicarbonate solution, washed with deionized water three times, and dried to prepare the product I. 3 As a solvent, NMR characteristic absorption spectrum (such as figure 1 Shown): δ=8.32~8.35(a, 2H), δ=7.84~7.88(b, 4H), δ=7.35~7.39(c, 8H);

[0048] Step two:

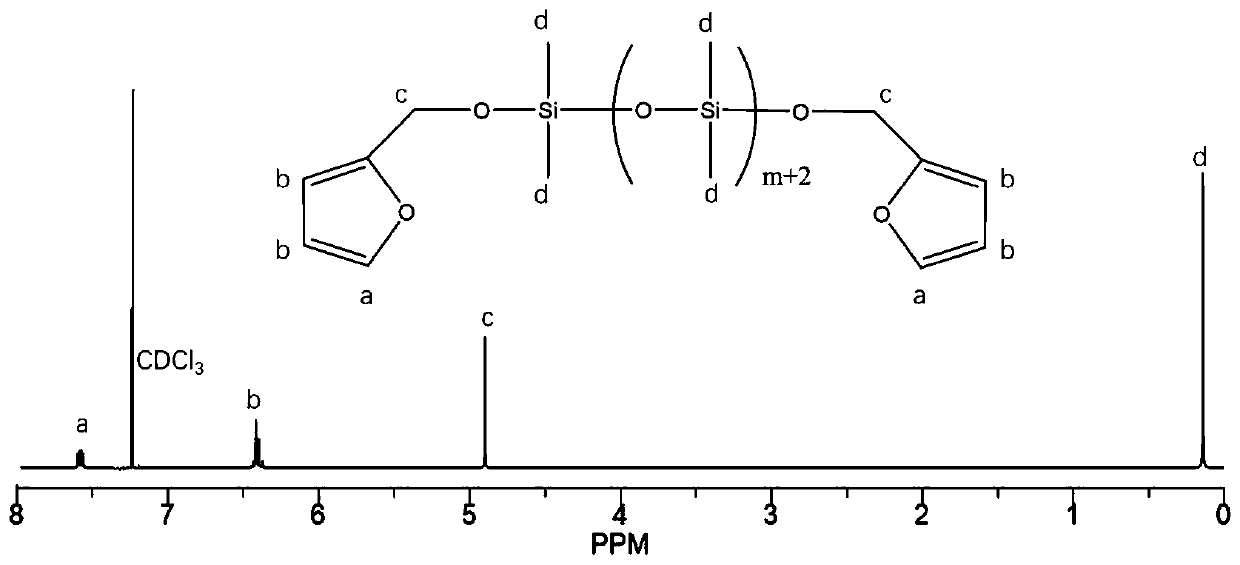

[0049]Add 2 parts of dichlorodimethylsilane to the solvent et...

Embodiment 2

[0055] A preparation method of self-healing modified silicone rubber, specifically comprising the steps of:

[0056] step one:

[0057] Add 1.0 parts of phenylenediamine and 0.6 parts of pyromellitic anhydride to dimethylacetamide, stir at room temperature for 6 hours, add 0.3 parts of maleic anhydride, continue the reaction for 4 hours, add 1.8 parts of triethylamine and 1.8 parts of acetic anhydride parts, the temperature was raised to 60°C, and the reaction was carried out for 8h. The reaction solution was poured into petroleum ether, and a large amount of solid precipitated, filtered, and the obtained solid was washed three times with 5 wt% sodium bicarbonate aqueous solution, three times with deionized water, and dried to prepare product I.

[0058] Step two:

[0059] Add 2 parts of dichlorodimethylsilane to the solvent ethyl acetate, and 5 parts of triethylamine as an acid-binding agent, place it in an ice bath, and then add dichlorohydrin dropwise through a constant p...

Embodiment 3

[0065] A preparation method of self-healing modified silicone rubber, specifically comprising the steps of:

[0066] step one:

[0067] Add 1.0 parts of phenylenediamine and 0.9 parts of pyromellitic anhydride to dimethylacetamide, stir at room temperature for 8 hours, add 0.5 parts of maleic anhydride, continue the reaction for 3 hours, add 2.0 parts of triethylamine and 2.0 parts of acetic anhydride parts, the temperature was raised to 60°C, and the reaction was carried out for 8h. The reaction solution was poured into petroleum ether, and a large amount of solid precipitated, filtered, and the obtained solid was washed three times with 5 wt% sodium bicarbonate aqueous solution, three times with deionized water, and dried to prepare product I.

[0068] Step two:

[0069] Add 2 parts of dichlorodimethylsilane to the solvent ethyl acetate, and 6 parts of triethylamine as an acid-binding agent, place it in an ice bath, and then add dichlorohydrin dropwise through a constant p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com