Fireproof and waterproof composite floor and fireproof and waterproof composite decoration board

A composite floor and composite panel technology, applied in floor coverings, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of natural environment damage, high price, gaps, etc., and achieve the goal of reducing production costs and protecting the natural environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

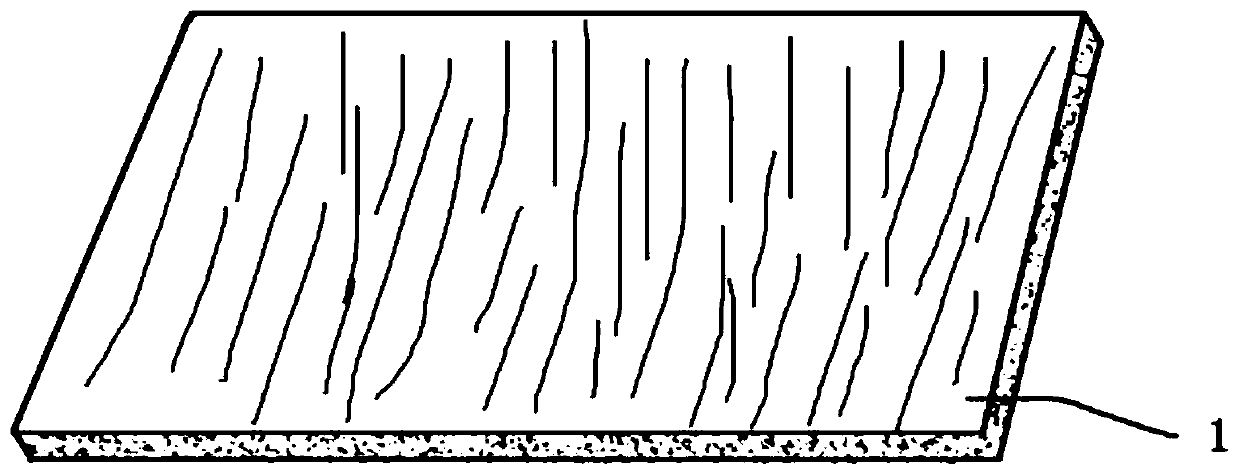

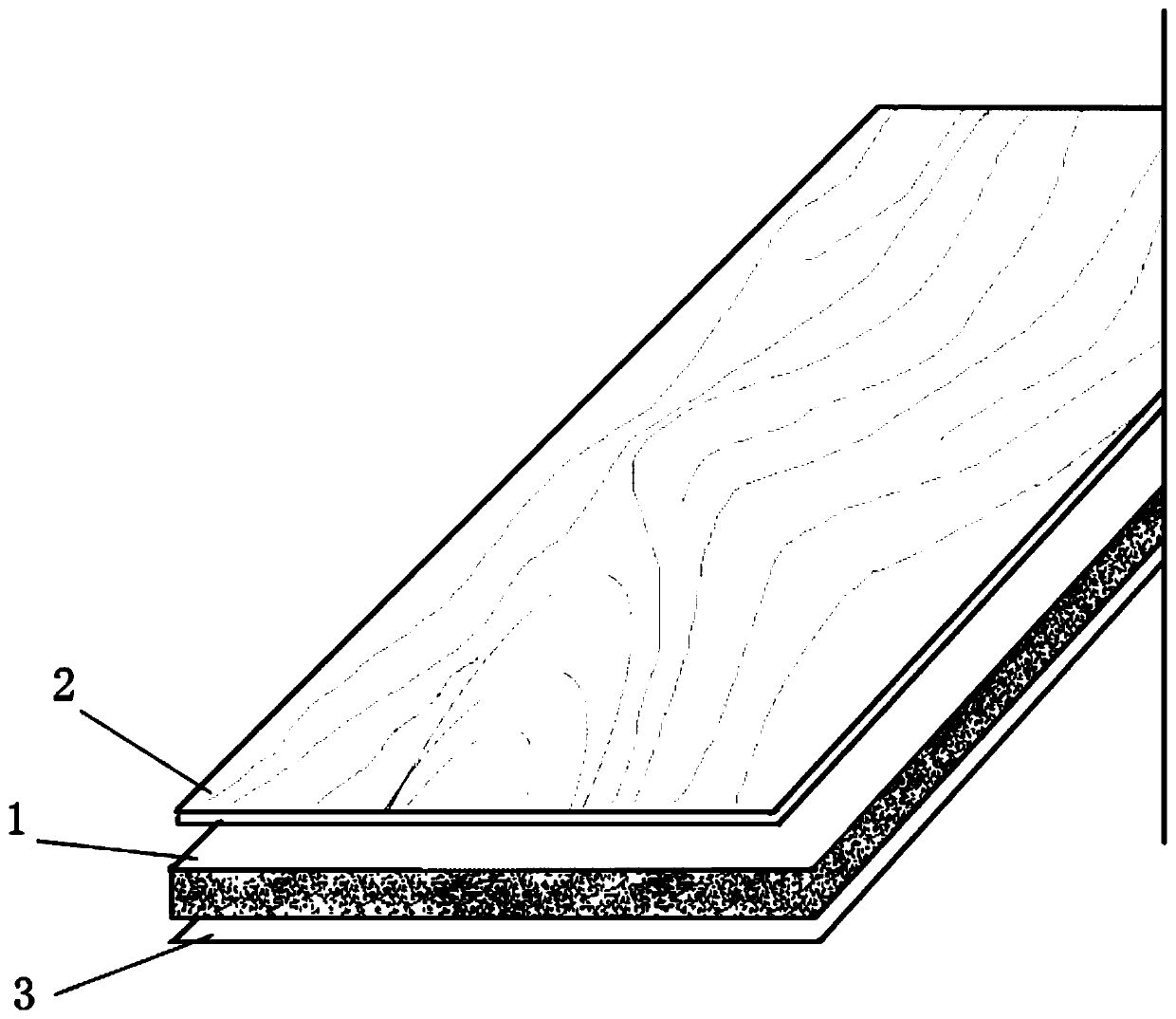

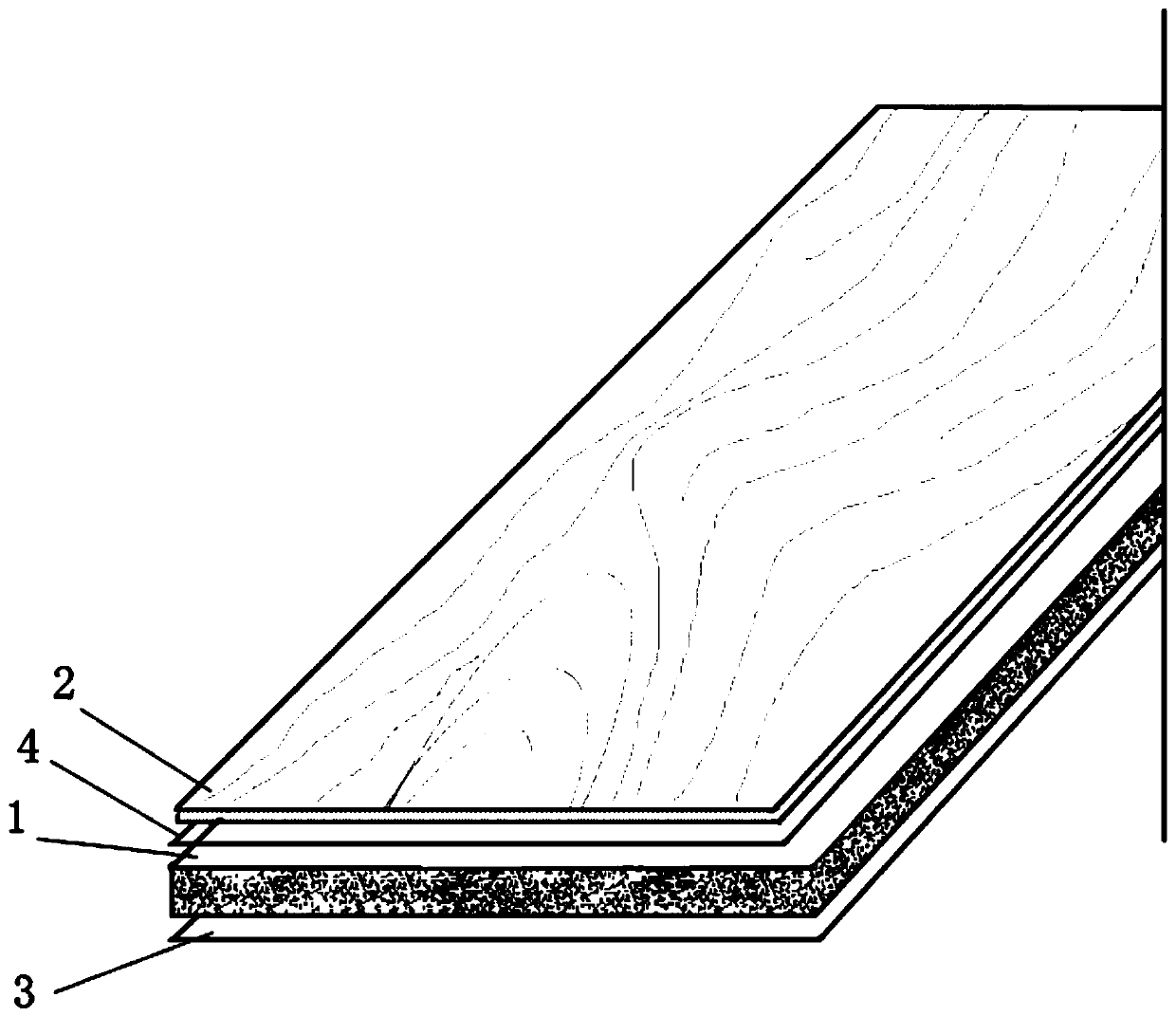

[0095] The raw materials of a fireproof and waterproof core material are as follows in parts by mass: 82 parts of PCB powder, 15 parts of PVC powder, and 3 parts of coloring agent.

[0096] The PCB powder used in this example is electronic circuit board resin powder obtained by recycling waste electronic circuit boards, and the colorant is titanium dioxide.

[0097] The fireproof and waterproof core material of this example can be synthesized by processing each raw material of the fireproof and waterproof core material through an internal mixer.

Embodiment 2

[0099]The raw materials of a fireproof and waterproof core material are as follows in parts by mass: 65 parts of PCB powder, 15 parts of bakelite powder, 15 parts of PVC powder, 3 parts of coupling agent, 3 parts of coloring agent, and 0.001 parts of copper powder.

[0100] The PCB powder used in this example is electronic circuit board resin powder obtained from leftover scraps, the bakelite powder is obtained by crushing waste bakelite products, the coupling agent is KH-550, and the colorant is titanium dioxide.

[0101] The fireproof and waterproof core material of this example can be synthesized by processing each raw material of the fireproof and waterproof core material through an extruder.

Embodiment 3

[0103] The raw materials of a fireproof and waterproof core material are as follows in parts by mass: 30 parts of PCB powder, 50 parts of bakelite powder, 10 parts of epoxy resin glue, 5 parts of antioxidant, 3 parts of colorant, and 0.001 parts of aluminum powder.

[0104] The PCB powder used in this example is electronic circuit board resin powder obtained by recycling waste electronic circuit boards, the bakelite powder is obtained by crushing waste bakelite products, the antioxidant is antioxidant 168, and the colorant is carbon black.

[0105] The fireproof and waterproof core material of this example can be synthesized by processing each raw material of the fireproof and waterproof core material through a hot press.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com