P-type doped AlScN/AlScN superlattice barrier layer-based efficient light-emitting diode and preparation method

A technology of light-emitting diodes and barrier layers, applied in the field of microelectronics, can solve the problems of increasing the barrier height of hole injection quantum wells, reducing the luminous efficiency of light-emitting diodes, and reducing the efficiency of hole injection, etc., so as to improve performance indicators and increase concentration , The effect of increasing the barrier height

- Summary

- Abstract

- Description

- Claims

- Application Information

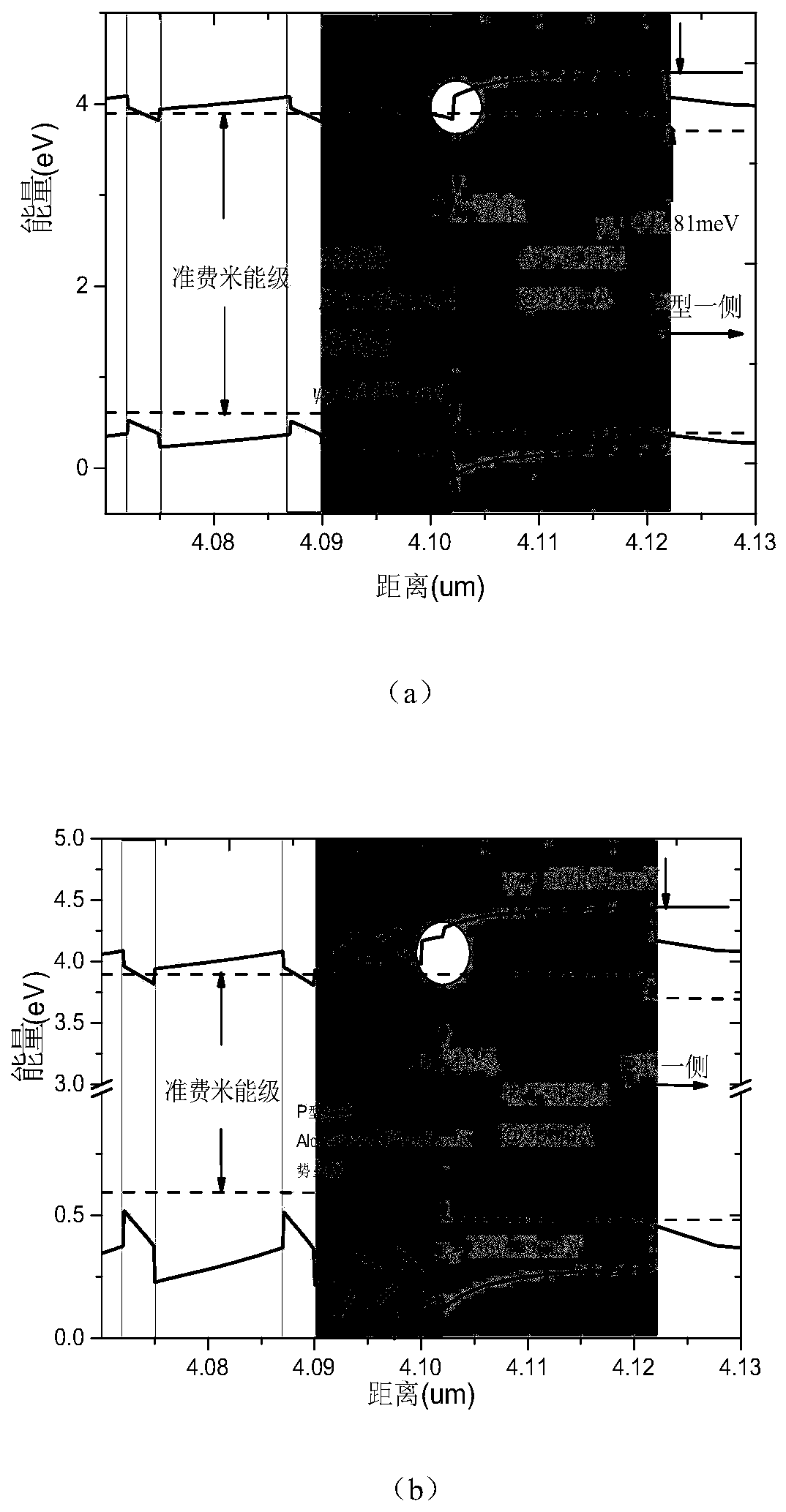

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

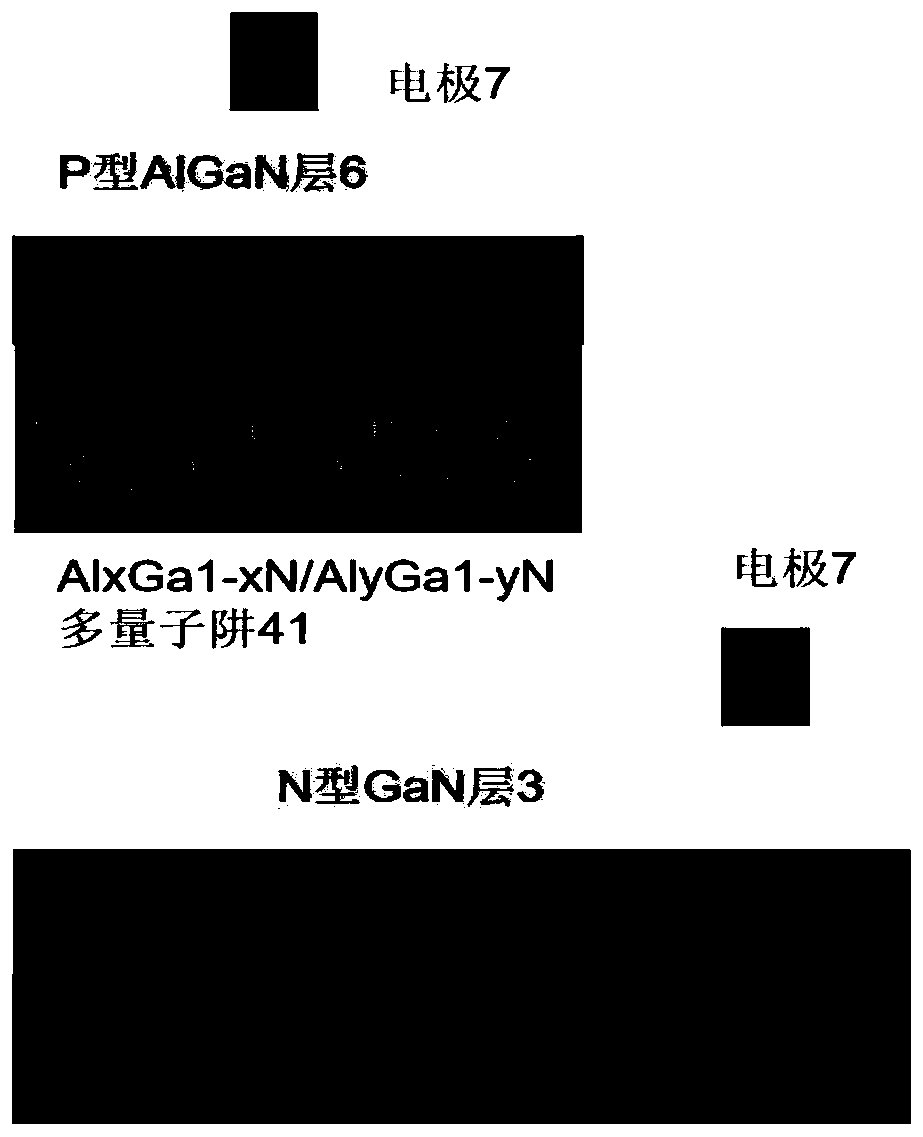

[0036] Example 1, preparing a light emitting diode with a light emitting wavelength of 365nm.

[0037] Step 1, pretreating the substrate substrate.

[0038] 1a) After cleaning the gallium oxide substrate, place it in the metal organic chemical vapor deposition MOCVD reaction chamber, and reduce the vacuum degree of the reaction chamber to 3×10 -2 Torr: Introduce hydrogen gas into the reaction chamber, and under the condition that the pressure of the MOCVD reaction chamber reaches 25 Torr, heat the substrate to a temperature of 900°C and keep it for 10 minutes to complete the heat treatment of the substrate;

[0039] 1b) The heat-treated substrate is placed in a reaction chamber with a temperature of 1000° C., and a nitrogen source with a flow rate of 3500 sccm is passed through, and the nitriding is carried out for 3 minutes, and the nitriding is completed.

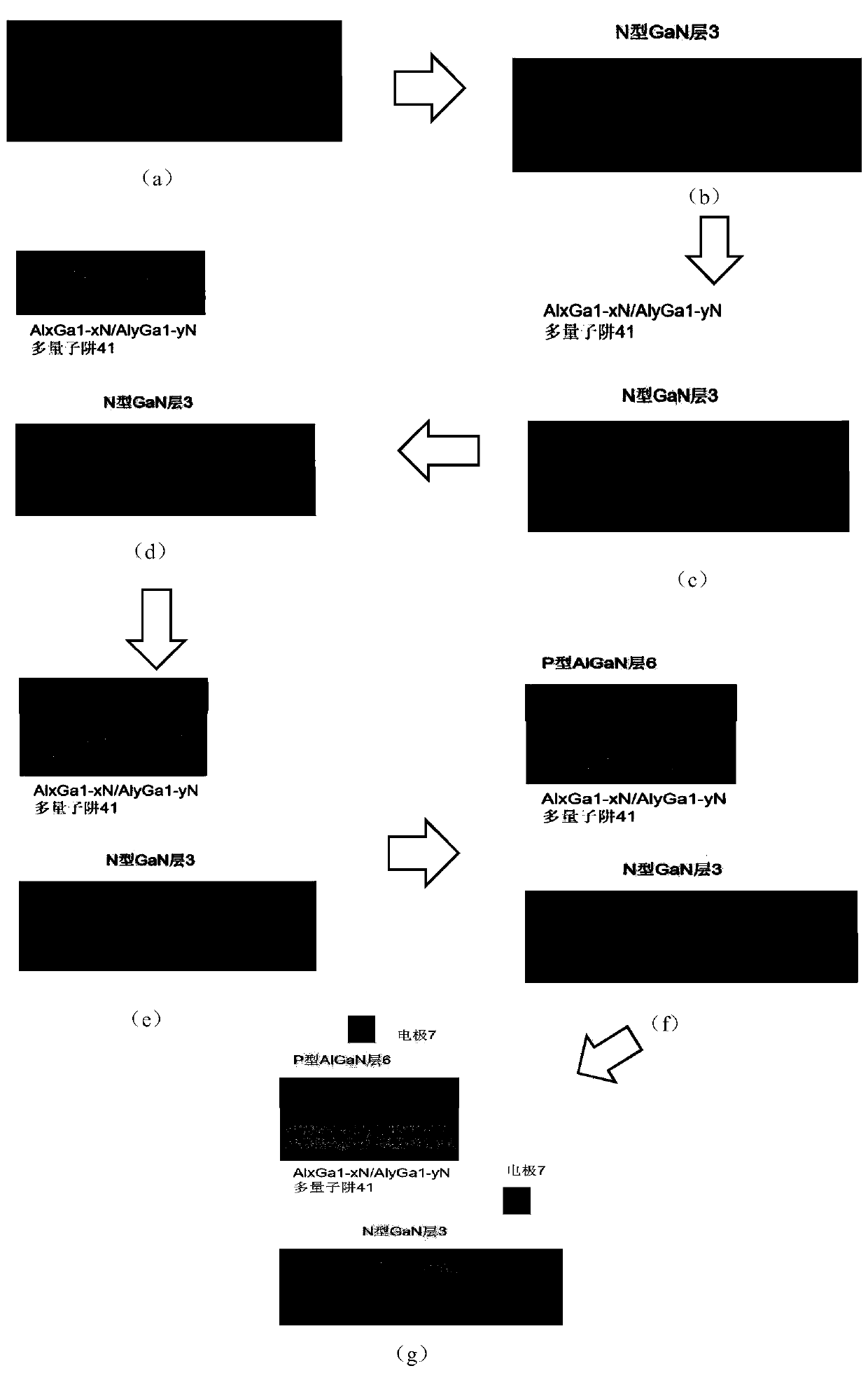

[0040] Step 2, growing a high-temperature AlN layer, such as figure 2 (a).

[0041] On the nitrided substrate, the ...

Embodiment 2

[0054] Example 2, preparing a light emitting diode with a light emitting wavelength of 283nm.

[0055] Step 1, pretreating the substrate substrate.

[0056] The specific implementation of this step is the same as step 1 of embodiment 1.

[0057] Step 2, growing a high temperature AlN layer, such as figure 2 (a).

[0058] On the substrate after nitriding, the MOCVD process is adopted. Under the condition that the temperature of the reaction chamber is 1200°C and the pressure of the MOCVD reaction chamber reaches 340 Torr, a nitrogen source with a flow rate of 3500 sccm and an aluminum source with a flow rate of 30 sccm are introduced simultaneously, and the growth thickness is 30nm high temperature AlN nucleation layer.

[0059] Step 3, grow n-type GaN layer, such as figure 2 (b).

[0060] On the AlN nucleation layer, the MOCVD process was adopted. Under the condition of the reaction chamber temperature of 1300°C, a nitrogen source with a flow rate of 2700 sccm, a galliu...

Embodiment 3

[0074] Example 3, preparing a light emitting diode with a light emitting wavelength of 233nm.

[0075] Step A, pretreating the substrate.

[0076] The specific implementation of this step is the same as step 1 of embodiment 1.

[0077] Step B, growing a high temperature AlN layer, such as figure 2 (a).

[0078] On the substrate after nitriding, the MOCVD process is adopted. Under the conditions of the temperature of the reaction chamber at 1300°C and the pressure of the reaction chamber at 400 Torr, a nitrogen source with a flow rate of 4000 sccm and an aluminum source with a flow rate of 40 sccm are simultaneously introduced, and the growth thickness is 50 nm. high temperature AlN nucleation layer.

[0079] Step C, growing an n-type GaN layer, such as figure 2 (b).

[0080] On the AlN nucleation layer, the MOCVD process was adopted. Under the condition of the reaction chamber temperature of 1500°C, a nitrogen source with a flow rate of 3000 sccm, a gallium source with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com